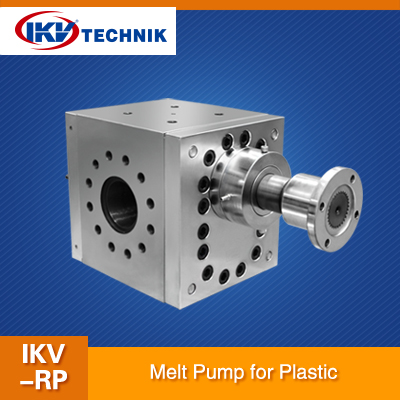

The melt pump operation instruction

IKV(Shanghai)Industry Co.,Ltd(Tel: Website: ) is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extruder lines in China. Our product widely used in plastic and rubber industry. Being a professional manufacturer, we are not only supply the best product. We also provide technical solutions for customs. We have been accumulating adequate experience on the application-specific technique.We have excellent team of engineers and quality control system to deliver quality value product and providing most important after sales service.

The melt pump operation instruction

1. The melt pump transport, storage to should take put down gently.After the arrival of the goods such as long time not to install use, should be to clean the shaft sealing, lifting the OM - 100 cc above series, melt pump lifting bolt should be used.

2. Use measurement inspection before installation, adjustment of pump and motor shaft concentricity shall ensure that the melt pump according to the order when at work indicate the direction of rotation, otherwise it will cause the input shaft fracture and damage of the pump body.The melt pump installed base should level off, and have enough intensity and rigidity.In the case of uniform bolt fastening, should guarantee the input shaft can no binding uniform rotation.Universal coupling installation error should not exceed the allowable deviation (10 °) or less, lest cause additional force, shorten the life of the shaft.Tighten the screws evenly as the strength should be installed.

3. The melt pump all pass the strict test run inspection before delivery, each index accords with a requirement, can be directly put into use after delivery.No matter what kind of specifications of the melt pump start using load load should be (around 5 RPM) running at low speed for a period of time, after waiting for each bearing place sufficient lubrication can be loaded up, slowly raise work pressure, after the overall operational condition is stable, can be gradually adjust pump and the whole system to the normal process speed and pressure.

4. Before operation, melt pump should be uniform heating, the temperature shall not exceed 120 ℃ per hour.In front of the pump not working temperature shall not be forced to start the melt pump.(working temperature is refers to the material used in the field process under the condition of molten melt temperature)

5. Fill in the material is used for sealing in the form of the melt pump, should timely adjust the sealing pressure builds position, ensure the best state seal.

Other supplier products

|

|

Performance analysis of the gear pump |

IKV(Shanghai)Industry Co.,Ltd(Tel: Website: ) is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed ... |

|

|

Inlaid round dripper style drip irrigation pipe |

IKV(Shanghai)Industry Co.,Ltd is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extrude... |

|

|

Inlaid flat dripper style drip tape machine |

IKV(Shanghai)Industry Co.,Ltd is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extrude... |

|

|

Fitting |

IKV(Shanghai)Industry Co.,Ltd is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extrude... |

|

|

Plastic Bottle Cap Extruder Line |

IKV(Shanghai)Industry Co.,Ltd is the leading manufacturer for melt pump, gear pump, metering pump, screen changer, die head, feed block and extrude... |

All supplier products

Same products