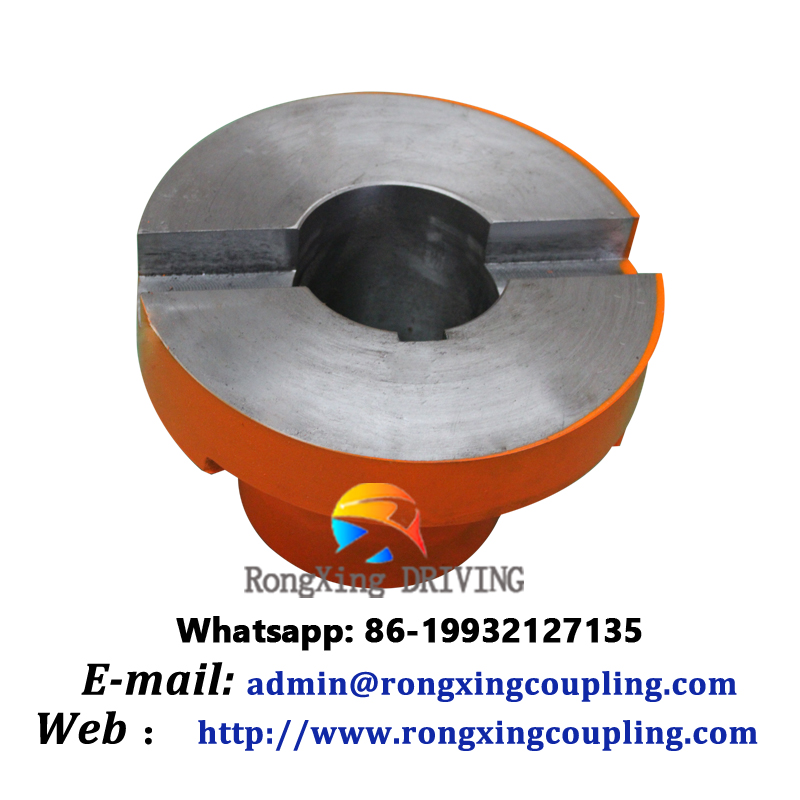

Intermediate Shaft Double Diaphragm Coupling For Mining Machinery Special Flexible Coupling

GⅡCL Drum Gear Coupling Suitable for connecting two horizontal coaxial axis drive shaft system, with a certain Angle to compensate the relative offset performance of two shafts drum tooth coupling, working environment temperature -20 ~ +80C, transmission nominal torque is 0. 4-4500KN-m

GⅡCL Drum Gear CouplingParameters And Dimensions mm

| Type | Nominal TorqueTnKN・m | Allowable Speed[n] r/min | Shaft Hole Diameterd | Shaft Hole LengthLY J, | D | D, | d2 | C | A | B, | Weightkg | Inertia Momentkg • m2 |

| GHCL1 | 0.4 | 4000 | 16 〜35 | 38 〜82 | 103 | 71 | 50 | 8 | 36 | 76 | 5. 1 | 0. 0037 |

| G1ICL2 | 0.71 | 4000 | 20 〜45 | 44 〜112 | 115 | 83 | 60 | 8 | 42 | 88 | 6.2 | 0. 0067 |

| GIICL3 | 1. 12 | 4000 | 22 〜56 | 44 〜112 | 127 | 95 | 75 | 8 | 44 | 90 | 8.6 | 0.0113 |

| GIICL4 | 1.8 | 4000 | 38 〜65 | 60 〜142 | 149 | 116 | 90 | 8 | 49 | 98 | 14.5 | 0. 0245 |

| G1ICL5 | 3. 15 | 4000 | 40 〜75 | 84 〜142 | 167 | 134 | 105 | 10 | 55 | 108 | 19.6 | 0. 0433 |

| GIICL6 | 5.0 | 4000 | 45 〜90 | 84 〜172 | 187 | 153 | 125 | 10 | 56 | 110 | 31.2 | 0. 0843 |

| GIICL7 | 7. 1 | 3750 | 50 〜105 | 84 〜212 | 204 | 170 | 140 | 10 | 60 | 118 | 47.5 | 0. 151 |

| GIICL8 | 10.0 | 3300 | 55 〜115 | 84 〜212 | 230 | 186 | 155 | 12 | 67 | 142 | 60.2 | 0. 241 |

| GIICL9 | 16.0 | 3000 | 60 〜135 | 107〜252 | 256 | 212 | 180 | 12 | 69 | 146 | 95.8 | 0. 470 |

| GII CLIO | 22.4 | 2650 | 65 〜150 | 107〜252 | 287 | 239 | 200 | 14 | 78 | 164 | 119 | 0. 745 |

| GIICL11 | 32.5 | 2350 | 70 〜175 | 107〜302 | 325 | 276 | 235 | 14 | 81 | 170 | 189 | 1.588 |

| GIICL12 | 50.0 | 2100 | 75 〜200 | 107〜352 | 362 | 313 | 270 | 16 | 89 | 190 | 285 | 3. 055 |

| GIICL13 | 71.0 | 1850 | 150〜225 | 202〜352 | 412 | 350 | 300 | 18 | 98 | 208 | 360 | 4.918 |

| GIICL14 | 112 | 1650 | 170〜250 | 242〜410 | 462 | 420 | 335 | 22 | 172 | 296 | 544 | 9. 725 |

| GIICL15 | 180 | 1500 | 190〜285 | 282〜470 | 512 | 470 | 380 | 22 | 182 | 316 | 786 | 17. 45 |

| GIICL16 | 250 | 1300 | 220〜320 | 282〜470 | 580 | 522 | 430 | 28 | 198 | 354 | 1027 | 29. 1 |

| GIICL17 | 355 | 1200 | 250〜365 | 330〜550 | 644 | 582 | 490 | 28 | 209 | 364 | 1532 | 53. 725 |

| GIICL18 | 500 | 1050 | 280〜400 | 380〜650 | 726 | 658 | 540 | 28 | 222 | 430 | 2278 | 99.5 |

| GIICL19 | 710 | 950 | 300〜370 | 380〜650 | 818 | 748 | 630 | 32 | 232 | 440 | 3026 | 175.5 |

| GIICL20 | 1000 | 800 | 360〜540 | 450〜800 | 928 | 838 | 720 | 32 | 247 | 470 | 4430 | 360. 75 |

| GIICL21 | 1400 | 750 | 400〜600 | 540〜800 | 1022 | 928 | 810 | 40 | 255 | 490 | 6152 | 561.5 |

| GIICL22 | 1800 | 650 | 450〜680 | 540〜900 | 1134 | 1036 | 915 | 40 | 262 | 510 | 7738 | 904. 75 |

| GIICL23 | 2500 | 600 | 530〜770 | 680〜900 | 1282 | 1178 | 1030 | 50 | 299 | 580 | 11553 | 1725 |

| GIICL24 | 3550 | 550 | 560〜850 | 680〜1000 | 1428 | 1322 | 1175 | 50 | 317 | 610 | 16615 | 3131.75 |

| GIICL25 | 4500 | 460 | 670〜1040 | 780〜1100 | 1644 | 1538 | 1390 | 50 | 325 | 620 | 27797 | 7198. 25 |

| Note: 1. The weight and moment of inertia of the coupling are calculated according to the type J hole.2. It is recommended to choose the length of J-shaped hole.3. Nitriding and surface quenching shall be agreed in the contract. | ||||||||||||

Flexible Coupling , Flange coupling , sleeve coupling , clamp coupling , Rigid coupling , Flexible coupling , inelastic element flexible coupling , Flexible coupling for elastic elements , Slide block coupling , gear coupling , universal coupling , chain coupling , Elastic sleeve pin coupling , elastic pin coupling , quincund-shaped coupling , wheel type coupling , snake spring coupling , spring spring coupling , Non-metallic elastic element flexible coupling , column elastic sleeve pin coupling coupling , elastic dowel pin coupling , elastic dowel pin coupling , elastic block radial elastic dowel pin coupling , H elastic coupling , fan-shaped blocks of elastic coupling , Saddle live piece of elastic coupling , elastic pin coupling , elastic coupling , tyred coupling , metal elastic element flexible coupling , Diaphragm coupling , diaphragm disc coupling , serpentine spring coupling , spring spring coupling , flexible rod coupling , helical spring coupling , coil spring coupling , bellows coupling , elastic tube coupling , film coupling , floating disc , spring coupling , Lens cross coupling , sliding block coupling , cross universal coupling , tooth coupling , flange coupling , sliding block coupling , Cross slide coupling , Cross shaft universal coupling

Company: Hebei Rongxing Driving Equipment Technology Co., Ltd.

Contact: Spark Wang

Tel: 86-

Phone /

E-mail:

WEB :

Address: North side of Planning 4th Road, Southern Industrial New Town, Jizhou District,

Hengshui City, Hebei Province, China

Send product request

Other supplier products

| Stainless steel Spring type Bellows Coupling Elastic Coupling for rotary encoder 6-6mm | Snake Spring Coupling Housing is suitable for coaxial axis drive shaft system, with certain compensation performance of angular, radial and axia... | |

| customized SWC type universal flexible shaft coupling,coupling universal,universal crowfoot couplings | swc universal shaft coupling , Swc440 Universal Coupling , Swc Gland Universal Coupling , Swc 315 Universal Joint Cross Pack , swp universal shaft ... | |

| Wholesale Ball screw bracket plum Elastic universal hook coupling JM2-30 customize Aluminum alloy and stainless steel | The coupling is suitable for all kinds of coaxial drive systems, using nylon rod cross-sectional shear strength to transfer torque, transfer t... | |

| GL disc coupling aluminum alloy double diaphragm clamp series shaft couplings Diameter 34mm length 45mm flexible coupling | Main Parameters And Dimensions Of Quine Type Elastic Coupling With Brake Wheel JB/ZQ4728-2006 Model Nominal TorqueTn N.m Allowa... | |

| Good Quality Multi-function Electric Motor Shaft Flange Expansion Joint For Pipeline Snake Spring Coupling | Zl Elastic Pin Tooth Coupling is suitable for the drive shaft system of the coaxial line, using nylon rod longitudinal section shear streng... |