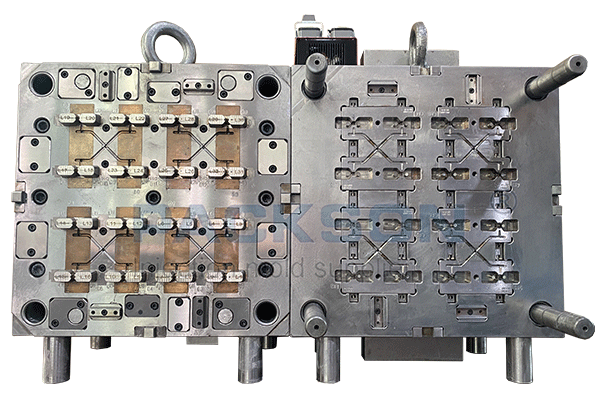

Multi-cavities Injection Molding

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold designis to produce multiples of the same part for high volume production since it means each production will produce a large number of finished parts. Multi cavity bait molddesign will help to make high-efficiency production.

Sometimes we will mix up the meaning of multi cavity moldand family injection molds. But these two types of injection mold are totally different. Family injection mold also includes multiple cavities but the shape of cavities is quite different. In other words, family mold is suitable for making different parts by a single run. The family mold can be much harder to maintain during production because of the different shapes of the cavities. It also increases the risk of molding defects.

With the rapid development of mold making,Packson moldalso makes the multi cavity mould for meeting the demands of customers. Especially for a medical industry like BD, they have the need for multi cavity soft plastic moldproduction. Such as disposable products: injection syringe, testing tube, and container. Feel free to contact us for further details of the multi cavity mold solutions today!

Multi Cavity Mould Parameters

|

Cavity Number |

2-120 cavities |

|

Plastic Resin |

PP,PP+20% GF,PA6,PLA,PE,PVC,PS,PC,POM,PET,ABS,TPE/TPR etc |

|

Tooling Material |

P20,NAK80,718H,S316H, etc. 20~60 HRC |

|

Mold Base |

LKM,HASCO,DME standard |

|

Mold Runner |

Cold and Hot Runner |

|

Mold Cold Runner |

Point way, side way, follow the way, direct gateway, etc. |

|

Mold Hot Treatment |

Nitridation, tempering, etc. |

|

Mold Surface |

texture, EDM, high gloss polishing |

|

Mold Cooling System |

water cooling or Beryllium bronze cooling, etc. |

|

Lead Time |

25-60 days |

Why Choose Multi Cavity Mould?

The Benefits of Multi Cavity Injection Molding

A

Multi cavity mould can be more than one cavity of the part with the same shape. Multi cavity injection molding is able to produce a large number of parts per molding cycle. It's suitable for high-volume production. Here are some other benefits of multi cavity injection mold:

Quick Lead Time: The cycle time of lead time will be shorter since numerous parts can be done per cycle.

Competitive Mold Cost: The cost of a mold with 2 cavities is cheaper and we will cost less than making 2 separate molds.

Low Part Price: Multi cavity mould helps reduce the part price by shorter labor and machine time.

Order Flexibility: It’s difficult to meet a demand for a million parts only by mold with a single cavity. Multi cavity moulds enable you to place large production orders that can be accomplished with high efficiency.

A Single Mold VS Multi Cavity Mold

A

A single cavity mold will create a single cycle while a multi cavity mold can make more than one product per cycle.

However, it's up to the customer's actual situation no matter they choose single or multi cavity mould. When customers require millions of the same parts with a short lead time and low part cost, a multi cavity mould is a good choice for them to get parts into the market quickly and competitively. But multi cavity moulds are not the best solution for all the projects since it requires more investment than single-cavity mold. Multi cavity mould needs substantial investment during or before project processing. Therefore we need to choose a suitable multi cavity mould solution according to the project property.

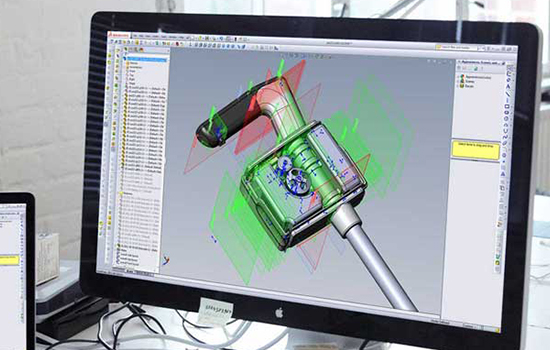

Process For Multi cavity Mould

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer.

Send us your part 3D to get your multi cavity mould and part quote.

Confirm quotation and order issues. Packson starts the multi cavity mold and part order process.

Making DFM and create processing solution.

Tooling design review by Packson engineers.

Get approval of the design. Packson start building your multi cavity mold.

Customer checks samples for approval.

Part mass production begins.

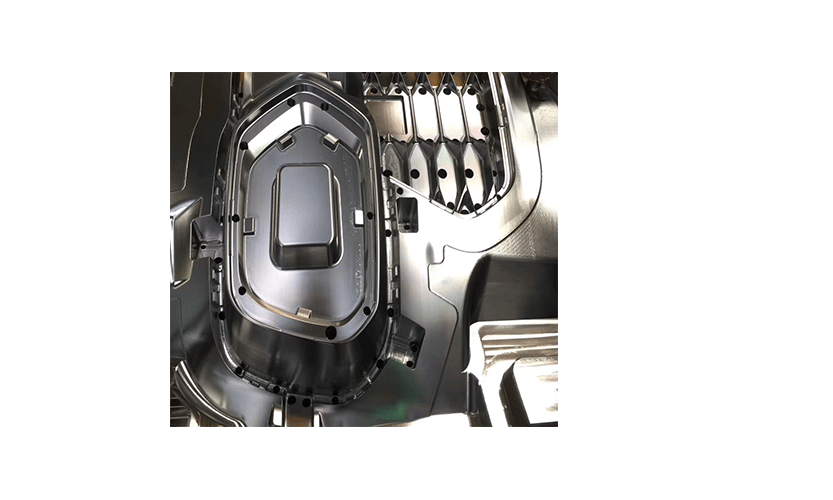

Applications Of Multi Cavity Mould

Packson creates single-cavity and multi cavity moulds for the medical and paramedical industry such as Y-bodies and straight connectors, caps, syringe plungers, syringe barrels, valve components, dispensers nozzles, etc.

From our mold case for medical, we have to build a 4 and 8 multi cavity mould with a full hot runner system also valve gates by rotary index system.

Packson has over 15 years of medical grade plastics injection moldingexperience. Our professional team who is an expert in custom multi cavity injection molding is ready to assist make a custom multi cavity injection molding solution for your application needs.

Send product request

Other supplier products

| Silicone Rubber Injection Molding | Silicone rubber injection molding has more than a half-century history since the late 1970s. There are two molding ways of silicone rubber injectio... | |

| Custom Metal Machining Parts | Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more. Our t... | |

| Plastic Injection Molding | Packson's injection molding machines range in capacity from 60-800T, providing a wide range of options for our clients. Our facility includes 40 se... | |

| Medical Plastic Injection Molding | Packson is not totally the same as other medical molding companies. Because we are an ISO-certified medical molding provider. Packson had got the c... | |

| Product Design & Development | In addition to providing moulding die designsolutions, we can also provide customers with product design optimization solutions to save more cost a... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |