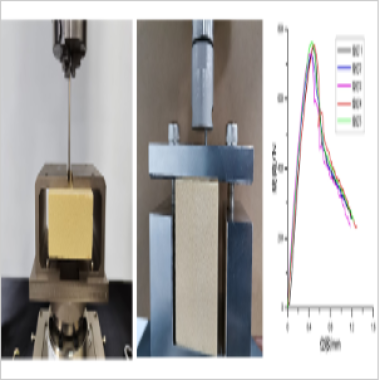

Socks wear tester

The Socks Wear Tester is a specialized testing instrument designed to evaluate the wear resistance, durability, and comfort of socks material. By simulating real-life wear and rubbing conditions, it provides objective data on abrasion, tearing, and overall performance, making it essential for quality control, product development, and research in the textile and apparel industry.

Application

The Socks Wear Tester can be applied in:

(1) Textile and Apparel Industry: Testing cotton, wool, synthetic fiber, and blended socks for wear resistance and durability.

(2) Footwear Industry: Evaluating knitted shoe liners or socks integrated into footwear.

(3) Material R&D: Assessing new yarns, coatings, or fabric treatments for enhanced wear resistance.

(4) Extended Applications: Can also be used for testing thin fabrics, textile coatings, and small polymer-based materials.

Specific products tested include: cotton socks, wool socks, synthetic athletic socks, blended fibers, and textile shoe linings.

Standards

The machine complies with international and national standards, including:

(1) EN 13770-2002 – Textiles – Determination of wear resistance of knitted footwear – Method C

(2) ASTM D4966 – Martindale Abrasion Tester standard

(3) ISO 12947 – Textiles – Determination of the abrasion resistance of fabrics by the Martindale method

(4) GB/T 3916-2008 – Textile testing for wear resistance

Features

(1) Dual workstations for simultaneous testing of two sock samples.

(2) Imported linear sliders ensure smooth and vibration-free operation.

(3) Large color touch screen with Chinese/English interface for easy control.

(4) Servo drive motor enables adjustable speed with low noise operation.

(5) Base treated with durable metal baking paint; electric control box also coated for long-term use.

(6) Sampling handwheel with thread-locking to prevent slippage.

(7) Cork-equipped leg surface to support accurate and consistent sample mounting.

(8) Supports multiple friction testing methods: Martindale (Lissajous curve), Schopper, and linear wear testing.

(9) Records the number of friction cycles until damage or thinning occurs for precise wear resistance analysis.

Parameters

| Parameter | Specification |

|---|---|

| Friction Frequency | 1 – 999,999 cycles, adjustable |

| Reciprocating Stroke | 1 – 30 mm |

| Reciprocating Frequency | 125 times/min |

| Workstations | 2 |

| Power Supply | AC 220 V ±10%, 50 Hz |

| External Dimensions (L × W × H) | 650 × 600 × 580 mm |

| Weight | 45 kg |

Accessories

(1) Main testing unit – 1 set

(2) Sample holders – 2 pcs

(3) Friction cloth/pads – 2 pcs

(4) User manual – 1 set

(5) Power cable – 1 pcs

(6) Certificate of Quality – 1 set

Test Procedures

(1) Mount the sock sample securely on the testing mold.

(2) Select the appropriate friction method (Martindale, Schopper, or linear).

(3) Set the friction frequency, stroke, and speed according to test requirements.

(4) Start the testing cycle. The friction head rubs the sock at a constant speed over the designated area.

(5) Observe the sample every 100–500 cycles to monitor for damage or thinning.

(6) Record the total number of cycles until wear occurs.

(7) Analyze the data to determine the sock’s wear resistance and compliance with standards.

Maintenance Information

(1) Keep friction pads and molds clean to maintain accuracy.

(2) Lubricate linear sliders and moving parts periodically.

(3) Inspect the servo motor and electronic components for proper function.

(4) Store the machine in a dry, dust-free environment.

(5) Calibrate the friction head and cycle counter regularly for consistent results.

Send product request

Other supplier products

| Xenon Arc Exposure Apparatus | Features and Benefits 1.The spectra of the xenon arc lamp and sunlight are highly convergent.Xenon arc exposure apparatusadopts quartz globe sea... | |

| Battery Slurry Resistance Tester丨Battery Slurry Resistance Test Mechine | Standard ASTM B193: Standard Test Method for Resistivity of Electrical Conductor Materials ISO 18516: Conductive Coatings – Measurement o... | |

| Bone Screw Pull-out Tester | Standard YY/T 1504. ASTM F543: standard specifies a test method for measuring the axial force required to extract or fail a metallic bone screw f... | |

| Protective Clothing Liquid Static Pressure Tester | Standards GB24540-2009,LFY-252 Instrument use The acid-proof clothing material anti-seepage acid static acid pressure tester is used to measure ... | |

| MST Medical Compression Stocking Tester,compression sock tester | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the compression performance, elasticity, and durabili... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |