Surgical Mask Flame Retardant Tester

The Surgical Mask Flame Retardant Tester is designed to evaluate the flame-retardant performance of surgical masks. In the event that a mask is accidentally exposed to flame, its flame-retardancy directly affects the safety of medical personnel. This instrument provides quantitative assessment of burning behavior, after-burning time, and smoldering, serving as a critical quality indicator for surgical masks.

The tester simulates actual use by mounting the mask on a head model and moving it over a flame igniter at a controlled linear speed, while recording flame interaction parameters.

Application

The Surgical Mask Flame Retardant Tester is applicable to flame-retardancy evaluation across the following industries and products:

(1) Medical and Healthcare Industry: surgical masks, disposable medical masks, N95/FFP masks, protective masks

(2) Protective Clothing Industry: flame-retardant facial protective equipment, medical gowns with mask integration

(3) Research and Development: development of flame-retardant mask materials, testing new mask prototypes, material performance evaluation

(4) Quality Control: production batch verification, monitoring mask compliance with flame-retardant standards

(5) Third-Party Testing Laboratories: certification testing, product performance verification, laboratory evaluations for regulatory compliance

The instrument is widely used for product development, production quality control, R&D, and laboratory testing.

Standards

The instrument complies with and can be applied to the following standards (including but not limited to):

(1) GB 19083-2010 – Technical Requirements for Medical Protective Masks — Synthetic Blood Penetration and Barrier Performance

(2) YY 0469-2011 – Technical Requirements for Medical Surgical Masks — Blood Penetration Test Device

(3) GB 2626-2006 – Respiratory Protective Equipment — Filtered Particulate Respirator — Flammability

(4) BS EN 136-1998 – Respiratory Protection Equipment — Full Face Mask Requirements — Flammability Test

Features

(1) Touch-tone and digital counting module control with automatic stop after preset time (1–99,999 s)

(2) Emulated human head model with metal mask clamp simulating actual mask usage

(3) High degree of automation: records burning time and flame-retardant time digitally

(4) Equipped with thermocouple flame temperature sensor and digital display

(5) Automatic ignition and adjustable flame height

(6) Precise linear movement of the head model for consistent flame exposure

(7) Safe observation through a box-type window with operation port

Technical Parameters

| Item | Specification |

|---|---|

| Test Mode | Automatic |

| Burner Timing | 0 – 9999.9 s |

| Linear Velocity of Head Model | 60 ± 5 mm/s |

| Distance Between Burner Tip and Mask | 20 ± 2 mm |

| Flame Height | 40 ± 4 mm |

| Flame Temperature | 800 ± 50 °C |

| Temperature Sensor | Thermocouple detection |

| Burner Height Adjustment Range | 30 mm |

| Wall Thickness of Head Model | 2 – 3 mm |

| Weight | 65 kg |

| Power Supply | 220 V, 50 Hz |

| Physical Dimension | 810 mm × 510 mm × 870 mm |

Accessories

Main test unit with box-type observation window

Metal head model with mask clamp

Automatic linear movement mechanism

Digital counting module

Thermocouple temperature sensor

Flame igniter assembly

Power cable

Operation manual

Calibration certificate

Test Procedures

(1) Mount the mask on the metal head model ensuring correct alignment

(2) Set linear movement speed, flame height, and burner timing according to test protocol

(3) Start automatic ignition and linear movement of the head model

(4) Observe burning behavior through the observation window

(5) Record after-burning and smoldering times, as well as flame-retardant performance

(6) Repeat test for multiple specimens or different flame conditions

(7) Clean head model, burner, and observation window after testing

Maintenance Information

(1) Clean the head model, burner, and observation window after each test

(2) Verify flame height and temperature sensor calibration periodically

(3) Inspect linear movement and automation system for proper function

(4) Check electrical and ignition components regularly

(5) Store the instrument in a clean, dry laboratory environment

Send product request

Other supplier products

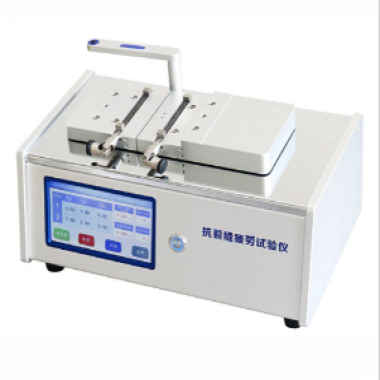

| Anti-crack fatigue tester | Standard HG/T 4343 ASTM E739 ASTM E647 GB/T 3075 Functional features High precision measurement: The accuracy of the test results can be ensu... | |

| Konan Tester | Product Description Conforms to the UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 11.5.1 Test 1(b): Kernan... | |

| Fabric textile 45 degree flammability tester | Applications: 45 degree flammability testeris designed to determine the burning characteristics of textiles. Stainless steel test cabinet with g... | |

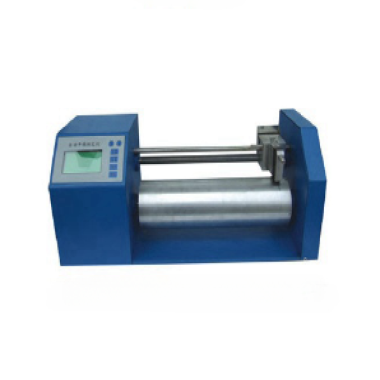

| Artificial turf wear tester | An artificial turf wear tester is a device specifically designed to evaluate the wear resistance of artificial turf. It tests the wear performance ... | |

| Ink drying apparatus device | How it works: The working principle of the ink drying instrument is based on simulating the drying environment of the ink in the printing process,... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |