Catheter Vacuum Leak Tester

The Catheter Vacuum Leak Tester is a professional device used to detect leaks in medical catheter systems under vacuum conditions. Its primary purpose is to ensure the sealing integrity and safety of catheters during use, preventing medical accidents caused by leaks. This tester can be widely used for leak detection in various medical catheters, such as suction catheters, drainage catheters, anesthesia catheters, and endotracheal tubes.

Applications

The catheter vacuum leak tester is a professional device used to detect leaks in medical catheter systems under vacuum conditions. It is mainly used to ensure the sealing and safety of catheters during use and prevent medical accidents caused by leaks. This tester can be widely applied to the leak detection of various medical catheters, such as suction catheters, drainage catheters, anesthesia catheters, endotracheal tubes, etc.

Standards

GB 15812.1 - 2005 :Non - Vascular Intravascular Catheters - Part 1: General Performance Test Methods

GB 8368 :Disposable Infusion Sets

YY 0489 - 2004 :Test Method for Piston Tightness of Disposable Sterile Syringes

Features

1. High-precision measurement: It can quickly and accurately detect the location and size of leaks in the pipeline system, enabling precise measurement of minute pressure changes and flow differences.

2. Safe and reliable: It prevents safety accidents and quality problems caused by leaks, ensuring the safety and stability of the production process.

3. Easy to operate: The operation interface is simple and clear, allowing users to complete the testing process by following the prompts. Some testers also feature user-level access control and a comprehensive password protection scheme to ensure data integrity, standardization, and traceability.

4. Multifunctional: Some advanced testers offer features such as real-time data display, data recording and analysis, test report generation, and multiple testing modes, meeting the needs of different users.

Technical Parameters

| Parameter | Specification |

|---|---|

| Measuring Range | Usually 0 to -90kPa, which can meet the negative-pressure testing requirements of various catheters |

| Accuracy | Generally reaching level 0.1 to ensure the accuracy of test results |

| Vacuum Maintenance Performance | Equipped with an automatic pressure-holding function to ensure the stability of the vacuum during the test |

| Test Time | Setting range: 1 to 9999 seconds; error ≤ ±1 second |

| Power Supply | Usually 220VAC 50Hz or 120VAC 60Hz, adapting to voltage requirements of different regions |

| Net Weight | Approximately 20kg (varies by model) |

Accessoriess

Standard accessories include: specialized connection adapters for different sizes of medical catheters (compatible with various catheter interfaces such as suction tubes and drainage tubes), vacuum-sealed connecting tubing (for connecting the main unit to the vacuum tank), sample fixing clamps (to secure the catheter under test), standard leak calibration components (to ensure the accuracy of the equipment's measurements), operating instructions, and a calibration certificate.

Test Procedures

Open-system catheter: Open the catheter vacuum control device to the release position, turn on the vacuum pump, and adjust the flow rate to the specified value (e.g., 30 L/min).

Closed-system catheter: Remove the pressure gauge, turn on the vacuum control device and vacuum pump, adjust the flow rate to the specified value, then switch the vacuum control device to the closed position, and reattach the pressure gauge. Read and record the residual vacuum value measured on the pressure gauge, which is usually expressed in kPa. For respiratory tract suction catheters, the residual vacuum should not exceed the specified value (e.g., 0.33 kPa or 3.4 cmH₂O).

Send product request

Other supplier products

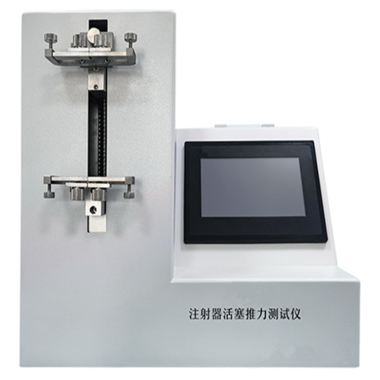

| Syringe piston thrust test device | Product introduction The syringe piston thrust tester is a kind of high precision and high stability measuring equipment, which is used to measure... | |

| Room Corner Test Machine, ISO 9705. En 14390 | Introduction: According to ISO 9705 of building materials fire prevention performance standards, this machine control platform to provide independ... | |

| Mask Bacterial Filtration Efficiency Tester | Medical Masks bacterial filtration efficiency tester also called BFE test machine is to determine the bacterial filtration efficiency (BFE) of medi... | |

| Cut Susceptibility Tester | Standard IEC 61730-2: Photovoltaic (PV) Module Safety Qualification – Requirements for Testing UL 1703: Flat-Plate Photovoltaic Modules and... | |

| FPC Flex Durability chamber | Standard ASTM F392 Product features 1. the stepper motor drive, high-precision positioning, low noise, can be used for a long time 2. program-c... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |