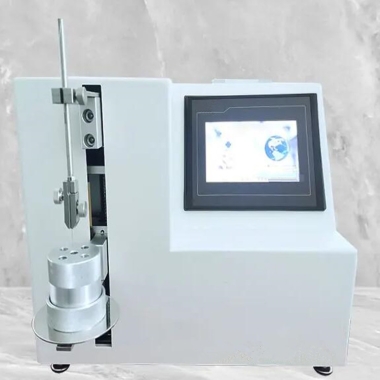

Guide pin anchoring force tester

The Guide Pin Anchoring Force Tester is designed to evaluate the anchoring performance of mammary positioning wires and guide needles. It ensures that the positioning filament remains stable within tissue, preventing displacement or dislodgement prior to surgery. This testing is essential for accurate tumor localization and safe surgical procedures.

Application

This instrument is suitable for a variety of medical and surgical applications, including:

(1) Mammary positioning wires for breast surgery – ensuring stability during preoperative procedures.

(2) Guide needles used in tumor localization – verifying anchoring effectiveness.

(3) Surgical R&D – testing new positioning wire or guide needle designs.

(4) Quality control in manufacturing – confirming the reliability of disposable guide needles and positioning filaments.

(5) Preclinical trials – simulating in-tissue performance of positioning devices.

Standards

The device is designed to meet the following standards:

(1) YY/T 0880-2013: Disposable Breast Positioning Wire and Guide Needle (China)

Optional international reference standards for extended compliance:

(2) ISO 10555-1: Sterile single-use intravascular catheters – General requirements

(3) ASTM F2084: Mechanical testing for medical guidewires

Features

(1) Accurately measures anchoring force to ensure clinical reliability.

(2) High-precision force sensor with hardware and software protection.

(3) Adjustable test speed and distance for flexible simulation.

(4) Built-in printer for immediate recording of test results.

(5) USB connectivity for data storage and export.

(6) Durable fixture made of high-quality 304 stainless steel.

(7) Simple operation with real-time force monitoring.

Parameters

| Parameter | Specification |

|---|---|

| Tensile force range | 0 – 20 N, accuracy ±1%, resolution 0.01 N |

| Test time | 1 – 999 s, error ±0.5 s |

| Test speed | 10 mm/min, 50 mm/min, 100 mm/min |

| Distance adjustment | 10 – 50 mm, adjustable |

| Force sensor | High-precision, with hardware/software protection |

| Fixture | 304 stainless steel |

| Force measuring mechanism | Built-in |

| Printer | On-board micro printer |

| Data storage | USB compatible, export to computer |

| Machine power | 70 W |

| Power supply | AC 90–240 V, 50 Hz |

Accessories

(1) Main test unit – 1 set

(2) USB storage device – 1 set

(3) Micro printer paper – 1 roll

(4) Operation manual – 1 set

(5) Optional fixtures/adapters for different guide needle diameters

Test Procedures

(1) Secure the guide needle or positioning wire into the stainless steel fixture.

(2) Adjust the test distance according to the sample size.

(3) Set the desired test speed and duration.

(4) Start the test; the instrument applies tensile force to the guide needle.

(5) Monitor the anchoring force in real-time.

(6) Test results are automatically recorded via the built-in printer and can be exported via USB.

Maintenance Information

(1) Keep the fixture, sensors, and printer clean and free of debris.

(2) Regularly calibrate the force sensor to ensure measurement accuracy.

(3) Avoid exposure to excessive moisture or vibration.

(4) Inspect mechanical components periodically for wear or loosening.

(5) Follow electrical safety standards during operation.

Send product request

Other supplier products

| Dispersion determination system for plastic carbon black | Scope of application: DW1431 plastic carbon black dispersion measurement system is based on a professional image acquisition system and correspond... | |

| Helmet Xenon Aging Tester | The helmet xenon lamp aging tester is a device that simulates the damage caused by long-term exposure of helmets to ultraviolet radiation from sunl... | |

| Electrode tortuosity tester & diaphragm ion conductivity tester | The Electrode Tortuosity Tester and Diaphragm Ion Conductivity Tester are precision systems designed for advanced analysis of battery electrodes an... | |

| Standard Helmet Visual Field Tester | The Standard Helmet Visual Field Tester is a precision instrument designed to evaluate the peripheral vision and visor obstruction of safety helmet... | |

| Mask Bacterial Filtration Efficiency Tester | Medical Masks bacterial filtration efficiency tester also called BFE test machine is to determine the bacterial filtration efficiency (BFE) of medi... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |