Solid Auto - ignition Point Tester

This tester determines the self - ignition characteristics of solid chemical products by placing the substances in a 20mm - side - length cubic wire mesh and increasing the temperature. It complies with standards such as GB/T 21756 - 2008 *Determination of the Relative Self - Ignition Temperature of Solid Substances in Chemical Products for Industrial Use* and NF T20 - 036.

Applications

This testing instrument provides data on the spontaneous combustion of solid products induced by high temperatures, thereby determining the spontaneous combustion properties of solid chemical products. The instrument is not suitable for explosive products, products that spontaneously combust at room temperature or in air, or products that melt under these experimental conditions. This instrument supports two testing modes: "Standard Test" and "Self-Test Mode." The "Standard Test" is used to determine the spontaneous combustion properties of solid substances, while the "Self-Test Mode" is used to calibrate the temperature sensor, ensuring the reliability of the test accuracy. This instrument meets all requirements for solid spontaneous combustion point testing and features automatic heating and temperature control functions, greatly facilitating the production and transportation supervision of solid substances.

Standards

It meets the requirements of GB/T 21756-2008 "Determination of Relative Autoignition Temperature of Solid Substances for Industrial Use", French National Standard NFT "Determination of Relative Autoignition Temperature of Solid Solids for Industrial Use", and NY/T1860 "Experimental Guidelines for the Determination of Physicochemical Properties of Pesticides" Part 24: Relative Autoignition Temperature of Solids.

Features

1. It adopts an embedded processor and the Windows CE operating system.

2. With an 8 - inch liquid - crystal touch screen, it can display the test status in real - time.

3. It supports two working modes, the "standard mode" and the "custom mode" (during the custom experiment, it can save the exothermic peak value in real - time, etc.), taking into account both the standardization and flexibility of the test.

4. It integrates high - temperature heat - insulation technology, temperature control, and precise detection technology.

5. It uses an electrically heated muffle furnace with natural air - circulation convection to ensure uniform heating of the samples.

6. The furnace cavity is made of heat - insulating vacuum ceramic fiber, which has a good heat - insulation effect.

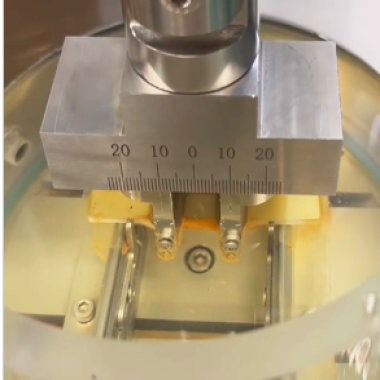

7. The cubic wire mesh is hung at the bottom of the furnace cover, making it safe and convenient to place samples.

8. It realizes automatic heating control, temperature control, and combustion detection.

9. A cleaning rod is provided for cleaning the inner cavity's central through - hole.

10. A debris tray is provided to collect samples falling from the wire mesh and residual samples cleaned out by the rod.

11. A cooling bracket is provided to place the assembled furnace cover on it for cooling after the test.

12. It uses a thermocouple sensor to quickly and accurately respond to temperature changes.

13. It displays the time - temperature curve in real - time, and the original data can be viewed.

14. The test process is fully automated, requiring no manual intervention. It supports functions such as parameter setting, data storage, and report viewing.

Technical Parameters

|

Working Environment |

(5~40)℃, <85%RH |

|

Test Objects |

Solid |

|

Temperature Control Range |

Room temperature~650℃ |

|

Standard Rise Rate |

0.5 ℃/min |

|

Customized Rise Rate |

(0.1~3.0)℃/min |

|

Temperature Measurement Range |

(0~800)℃ |

|

Temperature Measurement Resolution |

0.1 ℃ |

|

Temperature Measurement Accuracy |

±2.5 ℃ below 300 ℃ |

|

Heating Chamber Capacity |

±(0.75% of the reading) above 300 ℃ |

|

Timing Range |

2L |

|

Mesh Cage Size |

(0~96)h |

Accessoriess

1. Core Operating Components

Test Carrier Component: 20mm side length cubic metal mesh (for loading solid samples, matching standard test requirements);

Heating Unit: High-temperature muffle furnace with natural air circulation convection (ensuring uniform sample heating);

Furnace Chamber System: Vacuum ceramic fiber furnace chamber (excellent thermal insulation) + furnace lid with bottom hooks (for easy sample placement);

Temperature Monitoring Component: Thermocouple sensor (fast and accurate response to temperature changes);

Control and Display Module: Embedded processor, Windows CE operating system, 8-inch LCD touchscreen (real-time display of test status and time-temperature curve);

Operational Auxiliary Components: Cleaning rod (for cleaning the furnace chamber interior), debris tray (for collecting sample residue), cooling bracket (for placing the furnace lid for cooling after testing);

Functional Unit: Automatic heating/temperature control module (supporting precise temperature control).

2. Auxiliary Accessories

Sample Processing: Sample spoon (for quantitative solid sample taking), sample grinding/sieving tools (to ensure uniform sample particle size);

Calibration and Maintenance: Standard auto-ignition point sample (for instrument accuracy calibration), high-temperature resistant protective gloves (for operating the furnace lid);

Data Management: USB flash drive (for exporting test data, time-temperature curves, and reports).

Test Procedures

1. Core Operating Components

Test Carrier Component: 20mm side length cubic metal mesh (for loading solid samples, matching standard test requirements);

Heating Unit: High-temperature muffle furnace with natural air circulation convection (ensuring uniform sample heating);

Furnace Chamber System: Vacuum ceramic fiber furnace chamber (excellent thermal insulation) + furnace lid with bottom hooks (for easy sample placement);

Temperature Monitoring Component: Thermocouple sensor (fast and accurate response to temperature changes);

Control and Display Module: Embedded processor, Windows CE operating system, 8-inch LCD touchscreen (real-time display of test status and time-temperature curve);

Operational Auxiliary Components: Cleaning rod (for cleaning the furnace chamber interior), debris tray (for collecting sample residue), cooling bracket (for placing the furnace lid for cooling after testing);

Functional Unit: Automatic heating/temperature control module (supporting precise temperature control).

2. Auxiliary Accessories

Sample Processing: Sample spoon (for quantitative solid sample taking), sample grinding/sieving tools (to ensure uniform sample particle size);

Calibration and Maintenance: Standard auto-ignition point sample (for instrument accuracy calibration), high-temperature resistant protective gloves (for operating the furnace lid);

Data Management: USB flash drive (for exporting test data, time-temperature curves, and reports).

Send product request

Other supplier products

| Safety Footwear Compression Puncture Tester | Test purpose Measure the compression resistance of the shoe head cover and the puncture resistance of the steel plate to prevent the operator from... | |

| Battery Diaphragm Gas Permeability Tester | The Battery Diaphragm Gas Permeability Tester is a precision instrument designed to evaluate the gas permeability of battery diaphragms and separat... | |

| Initial Bonding Strength Testing Apparatus | The initial - tack tester, also known as the initial - tack property tester or adhesive tape tackiness tester, is an instrument specifically used t... | |

| 5-Station Seatbelt Webbing Abrasion Tester, ASTM D6770,commercial vehicle seat belt tester | The 5-Station Seatbelt Webbing Abrasion Tester is designed to evaluate the abrasion resistance of webbing materials used in seat belts, lap belts, ... | |

| Bone Cement Four-Point Bending Fatigue Tester | Standard YY/T 1429 (China): Specifies four-point bending fatigue tests for acrylic resin bone cements under quasi-static and cyclic loading. ISO ... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |