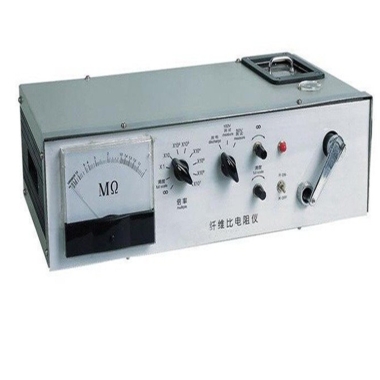

Fiber Blend Ratio Tester

The Fiber Blend Ratio Tester is designed to measure the electrical resistance of a compacted fiber sample and convert it into the specific resistance of the fiber according to its filling density. It provides accurate, repeatable measurements for fiber quality evaluation, research, and production control, suitable for textile, nonwoven, and fiber material laboratories.

Application

(1) Testing specific resistance of synthetic staple fibers such as polyester, rayon, acrylic, and nylon in textile manufacturing.

(2) Quality control and R&D of fiber blends in nonwoven fabrics, yarns, and felts.

(3) Evaluation of cotton, wool, and blended natural fibers for electrical properties.

(4) Measurement of resistance in technical textiles used in automotive, aerospace, and medical applications.

(5) Assessment of fiber-based materials for smart textiles, conductive fibers, and anti-static fabrics.

(6) Comparative analysis of recycled fibers or fiber mixtures for product development.

Standards

(1) GB/T 14342-1993: Synthetic short fiber specific resistance test method.

(2) GB/T 14342-2015: Updated national standard for specific resistance measurement of man-made staple fibers.

(3) ISO 2060: Determination of the fineness of fibers by electrical resistivity (analogous methodology).

(4) ASTM D4496: Standard test method for electrical resistance of textile fibers.

(5) EN 1149-1: Protective clothing—Electrostatic properties—Test method for surface resistivity of fibers and textiles.

(6) JIS L 1020: Test method for electrical resistance of textile fibers.

Features

(1) Standard Compliance: Fully adheres to GB/T 14342 and other international standards.

(2) Wide Measurement Range: Measures fiber specific resistance from 10^6Ω to 10^13Ω.

(3) Accurate Voltage Application: Provides stable 50V and 100V test voltages with less than 5% deviation.

(4) Stable Operation: Reliable in controlled temperature (20℃±2℃) and humidity (65%±10%RH).

(5) Low Zero Drift: Less than 4% over 1–8 hours under stable voltage with no signal input.

(6) High Basic Accuracy: Basic error ≤±20% relative to standard resistance measurements.

(7) Compact Design: Laboratory-friendly size (450×265×133 mm).

(8) Indirect Measurement: Converts measured bulk resistance of compacted fiber into specific resistance.

(9) Resistance Measurement System and Fiber Compaction Chamber: Ensures precise measurement.

Parameters

| Parameter | Specification |

|---|---|

| Fiber specific resistance range | 10^6Ω – 10^13Ω |

| Test sample weight | 15 g |

| Measurement voltage | 50V, 100V, deviation <5% |

| Working temperature | 20℃ ±2℃ |

| Working humidity | 65% ±10% RH |

| Zero drift | <4% over 1–8 hours |

| Basic measurement error | ≤±20% |

| Power supply | AC 220V |

| Overall size | 450 × 265 × 133 mm (L×W×H) |

Accessories

(1) Main unit

(2) Fiber compaction chamber

(3) Sample holder

(4) Power cable

(5) User manual

Test Procedures

(1) Prepare the tester and connect the power supply.

(2) Weigh 15 g of fiber sample and place it in the compaction chamber.

(3) Set the desired measurement voltage (50V or 100V) and ensure the environment meets the temperature and humidity requirements.

(4) Start the test; the instrument compacts the fiber and measures its resistance.

(5) The tester automatically calculates the specific resistance of the fiber.

(6) Record the displayed specific resistance values for analysis.

(7) Remove the sample and clean the compaction chamber after testing.

Maintenance Information

(1) Keep the compaction chamber clean to avoid residue affecting measurements.

(2) Check electrical connections regularly and ensure stable voltage supply.

(3) Calibrate periodically using standard resistors.

(4) Avoid exposure to moisture, dust, or corrosive substances.

(5) Store the instrument in a dry, controlled laboratory environment.

(6) Monitor zero drift periodically to maintain measurement reliability.

Send product request

Other supplier products

| Pipe coating scratch tester | The Pipe Coating Scratch Tester, also known as a paint and varnish scratch resistance tester or balanced scratch rod adhesion tester, is a precisio... | |

| Fabric thickness tester | Fabric thickness tester mainly used to measure the thickness of the fabric, suitable for leather, rubber and textiles and other materials, the thic... | |

| Programmable Ozone Test Chamber | study the effects of ozone on rubber, and then identify and evaluate the method to resist ozone and aging for rubber, adopt effective anti-aging me... | |

| SI80 Carbon Arc Aging Tester | Applications: Material Science: Accelerated aging tests for polymers, coatings, and textiles. Automotive Industry: Validation of exterior compone... | |

| Industrial Oven for Batteries | Features and Benefits 1.Real-time temperature monitoring, temperature range can be customized to +1000 ° C, +1200 ° C, accuracy ±0.... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |