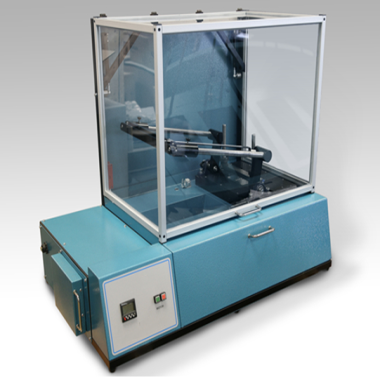

Metal Wire Wrap Tester

The Metal Wire Wrap Tester is designed to evaluate the ductility and winding performance of metallic wires. It measures the ability of wires to withstand plastic deformation under controlled tension and rotation, revealing surface defects such as cracks or inclusions that may not be visible otherwise. This instrument is widely used in metal wire production, quality control, research, and development to ensure consistent wire performance and compliance with national and international standards.

Application

(1) Testing ductility and plastic deformation of metallic wires.

(2) Detecting surface cracks, inclusions, and other defects in wires.

(3) Evaluating wire quality in steel manufacturing and wire production industries.

(4) Research and development of elevator ropes, cables, and spring wires.

(5) Quality inspection in factories producing bare or coated metal wires.

(6) Simulating forming and winding processes in wire-based applications.

(7) Testing wires used in automotive, aerospace, and construction industries.

(8) Educational and laboratory experiments in materials science and mechanical engineering.

Standards

(1) GB/T 2976 – Wire Winding Test Method for Metal Materials.

(2) ISO 4101 – Cold Drawn Steel Wire for Elevator Wire Ropes – Technical Specifications.

(3) ISO 7802:2013(E) – Method of Test for Wire Winding of Metallic Materials.

(4) GB/T 4909.7 – Bare Wire Test Methods – Part 7: Winding Test.

(5) ASTM standards related to metallic wire ductility and winding tests.

(6) DIN standards for wire winding and torsion evaluation.

Features

(1) Evaluates wire ductility under controlled tension and rotation.

(2) Detects surface defects such as cracks and inclusions.

(3) Provides standardized testing according to national and international standards.

(4) Ensures consistent wire quality and performance.

(5) Simulates real-world forming and winding processes.

(6) Adjustable parameters allow repeatable and precise testing.

(7) Suitable for production, R&D, quality inspection, and laboratory environments.

Parameters

| Parameter | Specification |

|---|---|

| Working power supply | AC 220V, 50Hz |

| Winding speed | 1–5 RPM, adjustable |

| Number of winding cycles | 1 cycle |

| Winding wheel diameter accuracy | ±0.5 mm |

| Damping system loading strength | 0–137 Kg |

| Damping system torque | 190 N·m |

| Pneumatic pressure | 0.4–0.7 MPa |

Accessories

(1) Main testing machine

(2) Winding wheel

(3) Pneumatic pressure system

(4) Damping system components

(5) Power cable

(6) User manual

Test Procedures

(1) Secure the wire sample on the winding station.

(2) Set the desired winding speed, number of cycles, and tension parameters.

(3) Start the machine and monitor the winding process.

(4) Observe the wire for any surface cracks, inclusions, or deformation.

(5) After the test cycle is complete, remove the wire and record the results.

(6) Repeat the procedure for multiple samples if necessary.

Maintenance Information

(1) Regularly inspect the winding wheel and damping system for wear or damage.

(2) Maintain pneumatic system pressure and check for leaks.

(3) Ensure electrical connections and power supply are stable and safe.

(4) Keep the machine and surrounding area clean to avoid contamination.

(5) Lubricate moving parts according to manufacturer guidelines.

(6) Handle wire and machine components carefully to prevent damage during testing.

Send product request

Other supplier products

| Flammabillity Test Machine,BSS 7230 ,FAA.FAR.25.853 | Introduction The product is according to aviation standards FAR-25 Appendix F of the first part b (4), b (6), b (7) Equipment integrated appendix ... | |

| Shoe Shank Stiffness Tester | This machine evaluates the thermal insulation and moisture permeability performance of the entire shoe by measuring its heat retention, moisture ab... | |

| Minimum Ignition Temperature (MIT) – Dust Cloud Tester | Dust Cloud Minimum Ignition Temperature Tester is mainly used to assess the explosiveness of dust in the production and processing places such as a... | |

| Salt Spray Testing Machine | Meet the standard: GB/T2423.17 Product Introduction: This type of salt spray test chamber is one of the artificial climate environmental “... | |

| Leather Water Vapor Permeability Tester | The Leather Water Vapor Permeability Tester measures the ability of leather and leather-like materials to transmit water vapor. By assessing the we... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |