PVC Wood Plastic Foaming Door Production Line

This machine unit adopts the specially-designed SJZ80 or SJZ92 conical twin-screw extruder, imported transducer for speed adjusting, and imported RKC temperature control instrument, having a wide adjusting scope, high temperature control precision, and convenient and reliable operation. The auxiliary machine comprises vacuum shaping platform, tractor, cutter, and loading rack. The equipment of enforced cooling device ensures the shaping effect of door plates. Claw type tractor adopts imported reducer motor and transducer and it’s distinguished by reasonable structure, large traction force, and stable traction. The cutter is reliable and stable in operation and accurate in cutting precision. The loading rack, equipped with movable loading trolley and special rubber protection layer, will not damage any materials and is convenient for use. The auxiliary machine unit adopts PLC control or domestic famous control system, reliable and stable.

Other supplier products

|

|

Vibration Sieve |

Vibration Sieve

1000.1200.1500

|

|

|

Twin-screw Extruders |

SJZ series cone twin-screw extruders are specially for various PVC powder materials. Mated with different moulds and auxiliary machinery, they can ... |

|

|

PVC Profile Bar Extrusion Production Line |

YF series PVC profile bar production line is mainly applied for extruding PVC door and window bars and multi-pore threading pipes (4-pore, 6-pore, ... |

|

|

UPVC PIPE PRODUCTION LINE |

GF series plastic pipe production line mainly produces PVC pipes of various calibrators and thickness for agricultural water supply and drainage, ... |

|

|

SRL-Z Mixing Machine |

Applied for various plastic dosing, mixing, drying, coloring, etc., it is the most ideal equipment of pipe manufacturers.

■ Main shaft sealing devi... |

All supplier products

Same products

|

|

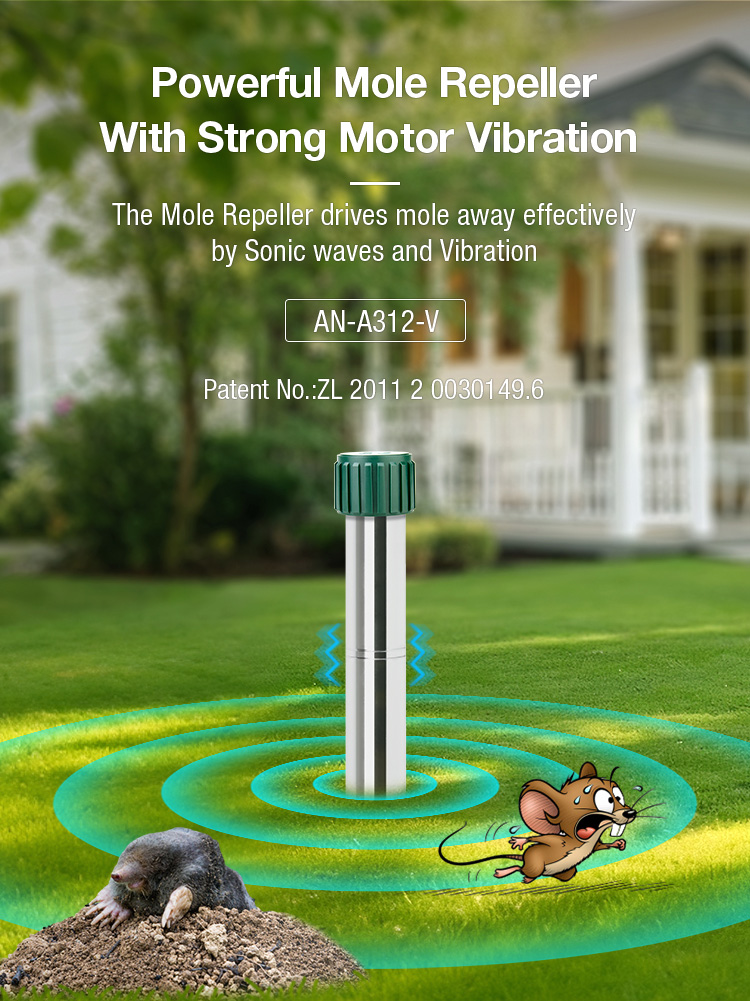

AOSION® Battery Sonic Vibrating Vole Mole Repeller With Motor AN-A312-V |

Seller: Aosion International(Shenzhen) Co., Ltd. |

1. The Vibrating Mole Repeller emits low frequency sound which vibrates the ground in a circular ... |

|

|

AOSION® Portable Ultrasonic Battery Mouse And Rat Repeller AN-A368 |

Seller: Aosion International(Shenzhen) Co., Ltd. |

1. Using ultrasonic to chase mice and other pests(like mosquitoes, flies, rats, wasps, etc...), i... |

|

|

High Quality Luxury Light Steel Villa |

Seller: Hebei Jiacheng Integrated Housing Co., Ltd |

High Quality Luxury Light Steel Villa

Double wing expansion box, with strong space expandability... |

|

|

Summer Vacation Style Luxury Villa |

Seller: Hebei Jiacheng Integrated Housing Co., Ltd |

Summer Vacation Style Luxury Villa

Packing houses are usually constructed with steel frames, mat... |

|

|

Portable Birch Wood Cutlery Set Wooden Spoon Knives Fork for Restaurants |

Seller: Yiwu Mengte Commodities Co., Ltd. |

Wood cutleryrefers to eating utensils made entirely out of wood, including spoons, forks, and kni... |