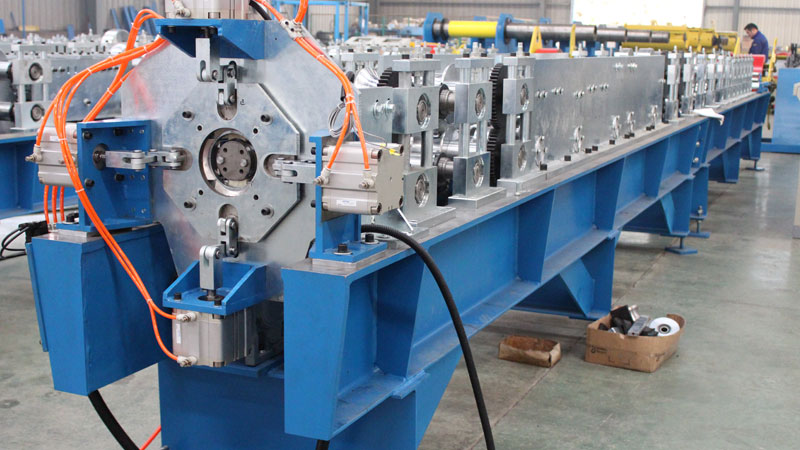

Ridge Cap Roll Forming Machine

The series of metal roof ridge cap machine are mainly used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge capping is placed along the peak of a roof to cover where the roof sheets meet. Roll-top ridge capping is a rolled product that is made to specific dimensions and cut to requested lengths. We manufacture both standard size ridge capping roll forming machines and customized roll forming machines.

Features and Advantages of Ridge Cap Machine

Capable of producing ridge capping under mass-production with different sizes and specifications.

Have the working speed choices ranging from 15m to 30m/min.

Certified with multiple patents

Prompt delivery for roof machine in stock.

Suitable Raw Material for roof ridge cap roll forming machine

Material type: Color coated Steel, Aluminum sheet

Thickness: 0.3-0.6(mm)

Yield Strength: 230-300/350 (MPa) optional

Width: 385 (mm) as profile requests

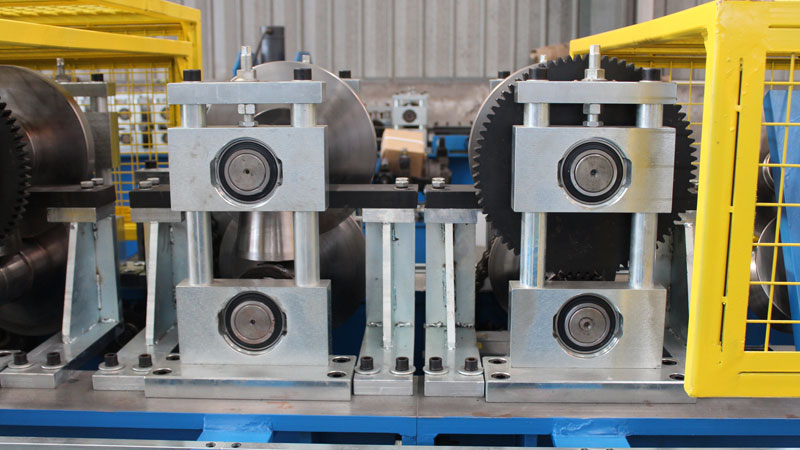

Production line Components and Parameters of Ridge Cap Roll Forming Machine

1. Decoiler 2t/3t/5t Motor/hydraulic motor/passive (optional)

2. Filming covering device optional

3. Front shear optional

4. Lubricating device no need

5. Roll forming system 15/20/30 m/min

6. Safety cover optional

7. Post cutting Motor/hydraulic (optional)

8. Output System Manual supporter/ Automatic Stacker (optional)

Stackmaster (Output direction) Lateral/Longitudinal (optional)

9. Hydraulic system Power supply for decoiler /post-cutting system

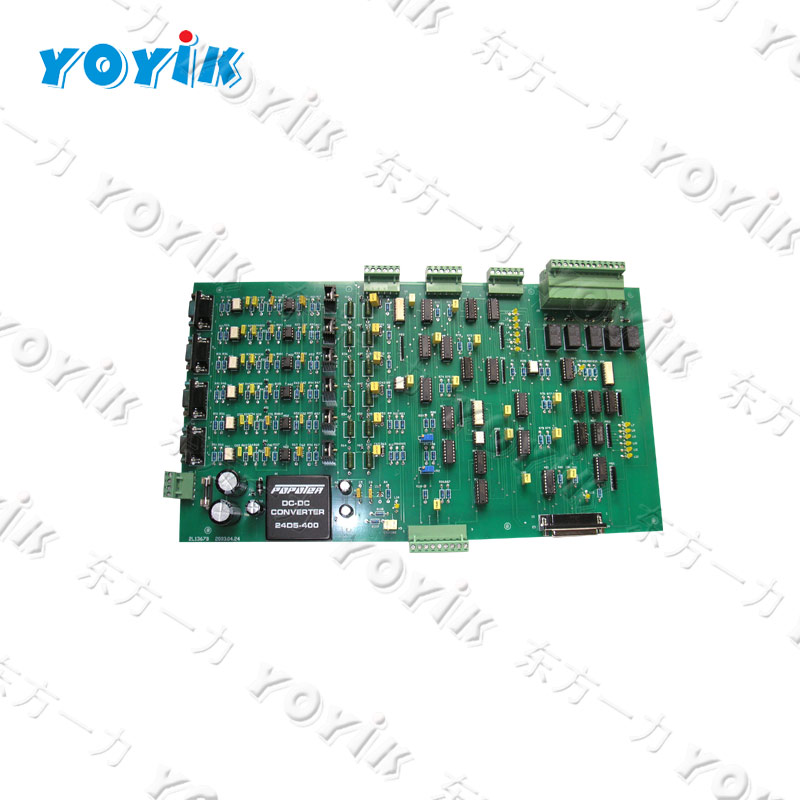

10. Electric control syste MITSUBISH/ SIEMENSE/AMS (optional or as requested )

Working Flow of Ridge Capping Roll Forming Machine

The general working flow of the metal ridge cap roof machine / ridge cap roof machines is as follows: Coil Charging Car (optional) - Decoiler (passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System - Step Punching unit(as profile requests) - Post-Cutting to length (Hydraulic/Motor) - Output Manual Supporter/Stackmaster(optional)

Application of Ridge Cap Roll Forming Machine

Roof ridge caps produced using this machinery are used for a variety of light steel structure construction and large building projects.

Specification of Ridge Cap Roll Forming Machine

Panel Shape As profile drawing and customer’s requirements

Operator needed 1 person

Power Supply 220V/380V/415V/460V, 50/60Hz, 3P (as requests)

Equipment Weight About 8t

Dimension (L*W*H) about 20*2.5*2m

LOADING SIZE Normally need 1x 40' container.

Equipment Color Normally Blue/White, or as requests;

Place of Origin Zhejiang, China (Mainland)

Packing Standard and careful export packing

As one of the most professional tube mill supplier, we provide roll forming equipment, coil upender, roll formed metal roof ridge cap,metal roof ridge cap roll forming machine, ridge cap forming machine and etc. For more information about

direct forming technology, please feel free to contact us!

Send product request

Other supplier products

| Round Downspout Roll Forming Machine | This round downspout machineis used to make round downspout. A downspout is a pipe that runs vertically along the side of the home. It is connecte... | |

| High Speed Double Deck Roll Forming Machine | Having 2 layers of guiding tables and the advanced roll forming and cutting to length systems, this series of high-speed double deckroll forming ma... | |

| Recoilers | Recoiler is the recoiling part of the slitting line. The used recoilers turns raw materials into coils by mechanical means. The recoiler is widely ... | |

| Garage Door Guide Rail Roll Forming Machine | This series ofgarage door roll former is used to make various guide rails. A guide rail is a device or mechanism to direct products, vehicles, or o... | |

| Horizontal Accumulator | Accumulators are divided into the horizontal accumulator and vertical accumulator. The vertical accumulator requires a high plant height due to its... |

Same products

| 9606 Angle Grinder Chamfering Stand | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | 1. High compatibility; fits over 90% of models on the market. 2. Constructed primarily from alum... | |

| 3025 Manual Ceramic Cutting Machine | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | The 3025 Manual Ceramic Cutting Machine is a versatile and reliable tool designed for precision c... | |

| China factory Open module ADAM-5056S for power station Sold by YOYIK | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | China factory Open module ADAM-5056S for power station Sold by YOYIK. Deyang YOYIK is a professio... | |

| Manual Tile Cutting | Seller: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | Manual tile cuttingis a skill that has been honed over centuries, a craft that requires patience,... | |

| Downspout Roll Forming Machine | Seller: Zhejiang Jinggong Science & Technology Co., Ltd. | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the c... |