Steel Coil Coating Production Line

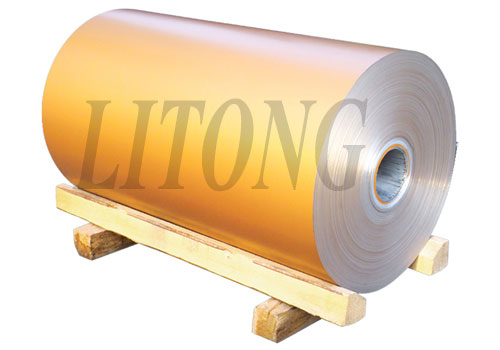

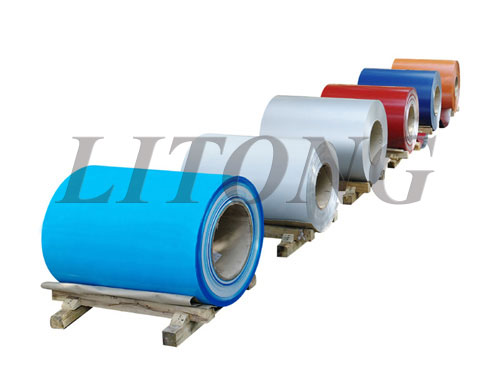

Main technical parameters Raw material: galvanized steel strip Roll coating technics: continuous triple coat and triple dry(Coat twice on back side, three times on front side) Steel coil weight: Max5000kg/coil Finished coil weight: Max5000kg/coil Steel coil OD: φ900~1600 mm Steel strip thickness: 0.19~0.8mm Steel strip width: 750~1250 mm Paints and coating pattern: PE for back and base,PVDF for face side The line speed: 30~60 m/min Instruction to Steel Coil Coating Line I. Technical parameters: 1、Roll coating technics: continuous triple coat and triple dry(Coat twice on back side, three times on front side) 2、Double uncoiling、with material storing loop 3、Structure pattern: uncoiling——coiling 4、Raw material: galvanized steel strip 5、Steel coil weight: Max5000kg/coil 6、Finished coil weight: Max5000kg/coil 7、Steel coil OD: φ900~1600 mm 8、Steel strip thickness: 0.19~0.8mm 9、Steel strip width: 750~1250 mm 10、Paints and coating pattern: PE for back and base,PVDF for face side 11、The line speed: 30~60 m/min 12、Energy source: natural gas and electricity power, the solid tunnel applies environment friendly and energy saving device to reach 10~35% of energy save. 13、Pretreatment: degrease with lye, roll coating for chromising without chrome ion release. 14、Speed before 1# storing group and after the 2# storing group is: 15~80 m/min 15、Color coating layer thickness: thickness of single dry film at face is 8~20μm,base paint thickness at both side can be adjusted between 2~15μm. 16、Coiling single layer error≤±1.0 mm 17、Annual output:37,000T/year(Calculate according 0.45mm×1220mm,speed 30m/min,daily work hours, 300days per year): 0.00045m×1.220m×30m/min×60min/h×16h/day×300day/year×7.8 =37,000ton/year

Send product request

Other supplier products

| Coated Aluminium Coil(PVDF) | Performance and usage PVDF coated aluminum coils are specially processed through the technics of roller coating and baking with precise paints from... | |

| Aluminium Coil(PE Colour Coated) | PE coated aluminum coil is processed through the technics of roller coating and baking with precise polyester paints. Its color is glossy and with ... | |

| Thermoplastic acrylic, Hydroxyl acrylic, Epoxy resin, PE, Isocyanate, Pigment, Additive, Solvent. | Usage of product Applied in machinery, instruments, hardware, electrical appliances, computers, bicycles, motorcycles, automobile, and various plas... | |

| MILL FINISH ALUMINIUM COIL | Alloy AA1100, AA3003, AA3005, AA3105, AA8011 Temper H16-18, H46 Thickness 0.15mm – 1.0mm Width 900mm – 1600mm Length 200m – 2000m | |

| heat-resistant paint | Usage of product Electrical appliances,inner and outer paint of non-sticky pan,ovens, electric irons, barrettes and so on,and other high temperatur... |