Catalytic combustion

Catalytic combustion is an efficient waste gas treatment method. Its main principle is to use a catalyst to oxidize and decompose combustible substances in the waste gas at a lower temperature (usually 200-400c). This method has low energy consumption, simple operation, safety and high purification efficiency, and is very suitable for the application of chemical industry, painting, insulating materials, coating production and other industries.

The basic principle of catalytic combustion is as follows: catalytic combustion, with the help of a catalyst, organic waste gas at a low ignition temperature, flame less combustion, and oxidation decomposition into carbon dioxide and water, at the same time release a large amount of heat.

Catalytic combustion process can be divided into:

The preheating type is the most basic process form of catalytic combustion. When the temperature of organic waste gas is below 100℃ and the concentration is low, the heat cannot be self-sufficient, so it needs to be heated in the preheating chamber before entering the reactor. Gas or electric heating is usually used to heat the exhaust gas to the ignition temperature required for the catalytic reaction. The purified combustion gas is heat exchanged with the untreated waste gas in the heat exchanger to recover part of the heat.

Organic waste gas has a high temperature and a high content of organic matter, so it is usually only necessary to set an electric heater in the catalytic combustion reactor to be used when starting combustion. The heat generated by part of the purified gas can be recovered through the heat exchanger, and the thermal balance can be maintained under normal operation without adding heat.

Send product request

Other supplier products

| S52 series centrifugal regeneration machine | The machine adopts turbo regeneration principle, the main use of the old rub between sand to achieve the objective of the membrane and rounded off ... | |

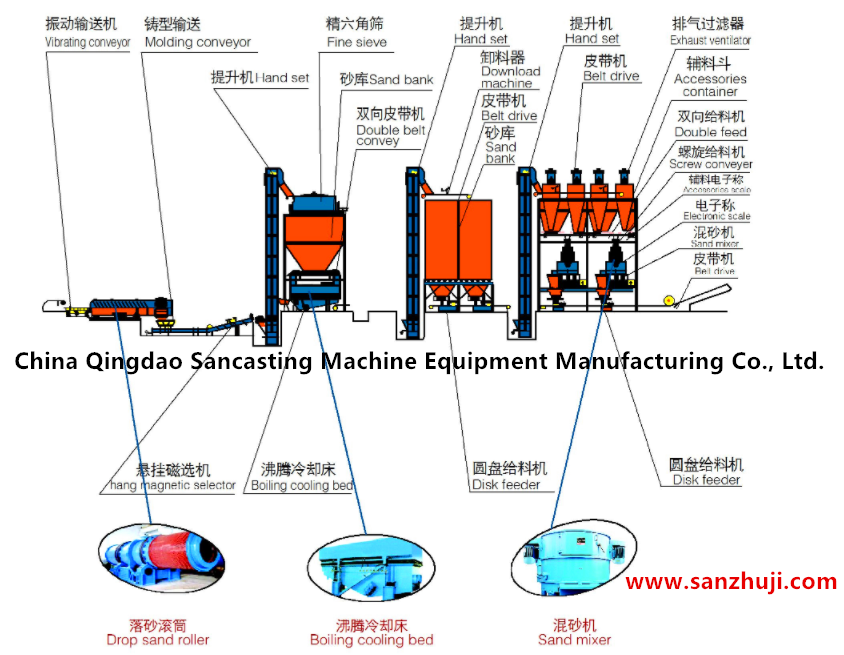

| Clay sand treatment process production line | Clay sand is the molding sand with clay as the binder. Sand treatment department is an important part of the foundry. Its main task is to provide q... | |

| S37 series tablet crusher | The machine is used to loosen the molding sand or break the old sand after flling on the assembly line of mechanized sand treatment of wet connecte... | |

| 28GN metal track shot blasting machine | ||

| S14 series rotor type sand mixer | Low speed scraper and medium speed rotor are best matched, the sand mixing capacity is large, the sand mixing ability is strong, the sand comprehen... |

Same products

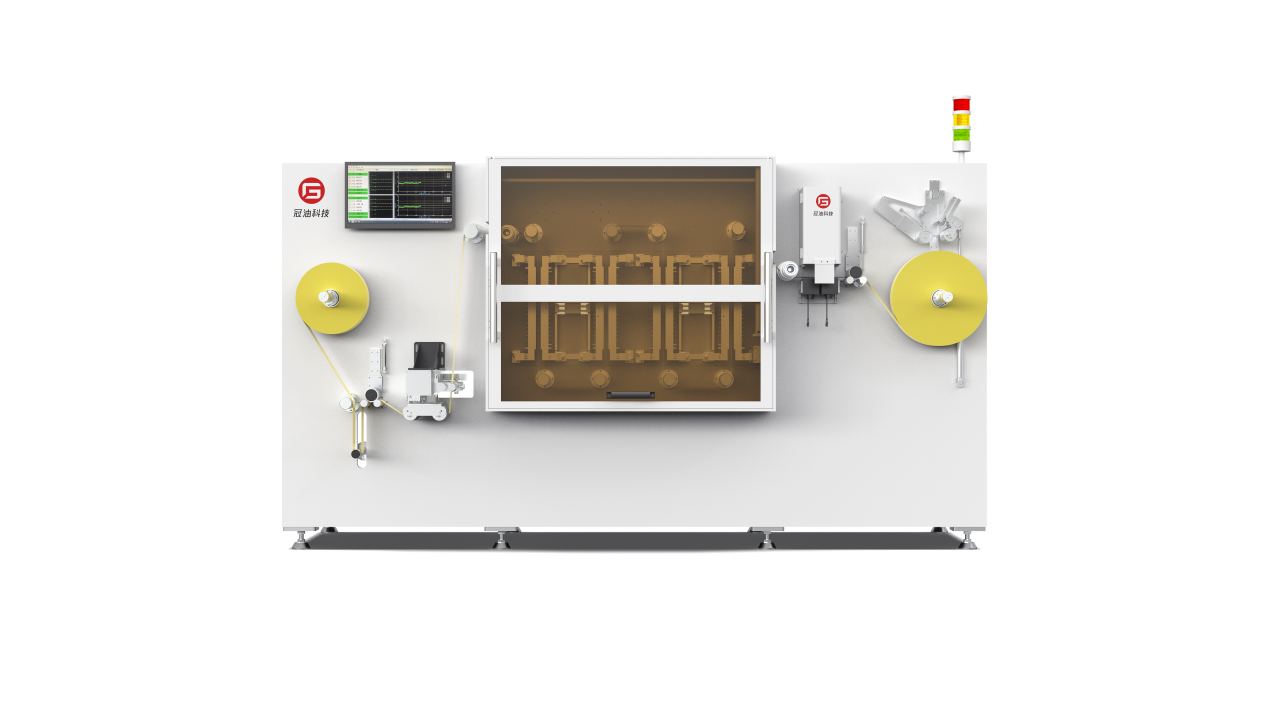

| The Single Workstation Electrostatic Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | The single workstation electrostatic perforating machineis a professional cigarette paper static ... | |

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |