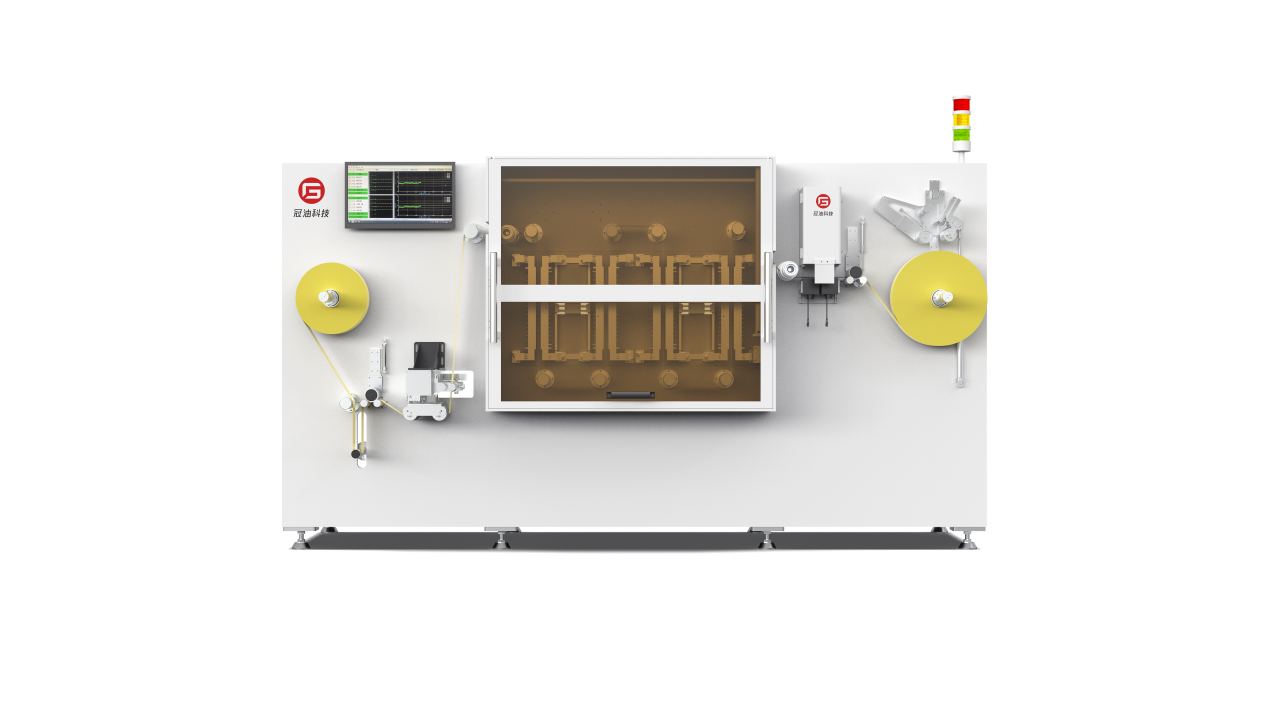

Multifunctional Closed stamping hydraulic press series

1.Product description

Multifunctional Closed stamping hydraulic press mainly used for metal thick and thin sheet drawing, blanking, flanging, bending, blanking and other forming processes. It also has the conventional functions of general hydraulic press and is widely used. Customerized as four-column type, frame type single-point closed type, double-point closed type and other machines according to users' requirements

2.Application

It is widely used in various fields such as automobiles, motorcycles, household appliances, petrochemical industry, rail transit, aerospace and so on. It is suitable for automobile parts, household electrical appliance parts, kitchen utensils, etc., especially for drawing and forming processes of special-shaped products, and pressing processes of metal or nonmetal parts, such as sheet drawing, bending, turning and forming.

3.Main Parameter model

| Multifunctional Closed drawing hydraulic press YM series | ||||||||||

| Item | Unite | YM-100 | YM-160 | YM-200 | YM-250 | YM-315 | YM-400 | YM-500 | YM-630 | |

| Nominal capacity | KN | 1000 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 6300 | |

| Slide stroke | mm | 300~2000 | 300~2000 | 400~2000 | 400~2000 | 400~2000 | 400~2000 | 500~2000 | 500~2000 | |

| Slide speed | Idle down | mm/s | 150/250 | 150/250 | 180/250 | 180/250 | 180/ 250/ 300 | 180/ 250/ 300 | 180/ 300/ 400 | 180/ 300/ 400 |

| Return | mm/s | 130/ 180 | 130/ 180 | 150/ 200 | 150/ 200 | 150/ 200/ 280 | 120/ 180/ 240 | 110/ 260/ 320 | 140/ 280/ 320 | |

| Working | mm/s | 10~25 / 10~25 | 10~25 / 10~25 | 6~15 / 8~20 | 6~15/ 8~20 | 6~15/ 8~20/ 12~30 | 6~15/ 10~25/ 12~30 | 5~13/ 12~30/ 15~37 | 6~15/12~30/15~37 | |

| Daylight opening height | mm | 500~2000 | 500~2000 | 600~2000 | 600~2000 | 600~2000 | 600~2000 | 700~2000 | 700~2000 | |

| Table size | F-B*L-R | mm | 700x 600 | 800x 650 | 900x 700 | 1000x800 | 1100x900 | 1200x1000 | 1300x1100 | 1400x1200 |

| 1000x800 | 1100x900 | 1200x1000 | 1300x1100 | 1600x1200 | 2000x1600 | 2200x1600 | 2200x1600 | |||

| 1500x1200 | 1600x1300 | 1700x1400 | 1000x1500 | 2200x1600 | 2600x1800 | 3600x 2200 | 3600x 2200 | |||

| Motor | KW | 11/15 | 18.5/22 | 18.5/22 | 18.5/30 | 18.5/ 30/ 37 | 30/37/60 | 30/ 67/ 74 | 37/ 74/ 97 | |

| Optional | knock out force / stroke | KN/mm | 200x150 | 300x150 | 400x200 | 500x 200 | 630x 260 | 800x300 | 800x300 | 800x300 |

| Moving working table | Direction | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | |

| Multifunctional Closed drawing hydraulic press YM series | ||||||||||

| Item | Unite | YM-800 | YM-1000 | YM-1250 | YM- 1600T | YM-2000T | YM--2500T | YM- 3000T | YM- 4000T | |

| Nominal capacity | KN | 8000 | 10000 | 12500 | 16000 | 20000 | 25000 | 30000 | 4000 | |

| Slide stroke | mm | 500~2000 | 500~2000 | 600~2000 | 600~2000 | 600~2000 | 700~2000 | 700~2000 | 700~2000 | |

| Slide speed | Idle down | mm/s | 180/ 300/ 400 | 200/ 300/ 400 | 200/ 300/ 400 | 200/ 300/ 400 | 200/ 300/ 400 | 200/ 250/ 300 | 200/ 250/ 300 | 200/ 250/ 300 |

| Return | mm/s | 120/ 230/ 270 | 140/ 220/ 300 | 170/ 250/ 340 | 150/ 240/ 300 | 110/ 220/ 300 | 150/ 200/ 240 | 170/ 230/ 270 | 170/ 230/ 270 | |

| Working | mm/s | 6~15/ 12~30/ 15~37 | 6~15/ 12~30/ 15~37 | 6~15/ 12~30/ 15~37 | 7~18/ 12~30/ 15~37 | 6~15/ 12~30/ 15~37 | 6~15/ 8~20/ 12~30 | 6~15/ 8~20/ 12~30 | 6~15/ 8~20/ 12~30 | |

| Daylight opening height | mm | 700~2000 | 700~2000 | 800~2000 | 800~2000 | 800~2000 | 900~2000 | 900~2000 | 900~2000 | |

| Table size | F-BxL-R | mm | 1500x1300 | 1600x1400 | 1700x1500 | 1800x1500 | 1900x1600 | 2000x1600 | 2100x1800 | 2200x1800 |

| 2600x1800 | 2600x1800 | 3600x 2000 | 3600x 2000 | 3600x 2000 | 4200x 2200 | 4200x 2200 | 4200x 2200 | |||

| 3600x 2200 | 3600x 2200 | 4600x 2600 | 4600x 2600 | 4600x 2600 | 5000x 2600 | 5000x 2600 | 5000x 2600 | |||

| Motor | KW | 60/ 104/ 111 | 67/ 111/ 148 | 74/ 148/ 222 | 111/ 148/ 185 | 111/ 222/ 296 | 148/ 222/ 296 | 222/ 259/ 370 | 296/ 370/ 444 | |

| Optional | Knock out force / stroke | KN/mm | 1000x300 | 1000x300 | 1250x 300 | 1600x400 | 2000x400 | 2500x 300 | 3150x 500 | 4000x500 |

| Moving working table | Direction | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | LR/FB | |

4. Advantage and characteristics

· Adopt integral frame structure, with strong rigidity and small deformation after artificial aging, polishing and antirust treatment.

· The sliding block movable plate has fast descending speed and high production efficiency. Pressure, stroke, and holding pressure can be adjusted according to pressing process requirements.

· New sealing element of oil cylinder, with high reliability and long service life.

· PLC circuit design, touch screen action optional operation, digital control.

· Large table top, large mold-mounting space, and eight long guide rails to ensure stable precision and product quality.

· The fixed-point and quantitative dilute oil continuous circulation cooling and lubrication system is adopted to make the engine run more safely.

5. Delivery date and quality assurance policy

Delivery period: 3-6 months.

Warranty period: 12 months.

Send product request

Other supplier products

| JH21 C Frame Pneumatic Press | JH21 Series pneumatic press machine adopted Japanese technology wet clutch is featured of stable working performance, high production efficiency, l... | |

| End cover pressing press machine supplier | Single-column hydraulic press is a multifunctional small and medium-sized hydraulic press. This series of C-type single-column hydraulic press mach... | |

| Hydralic Press Machine for bearing parts assembly | Hydralic Press Machine for bearing parts assembly | |

| Multifunctional Closed stamping hydraulic press series | 1.Product description Multifunctional Closed stamping hydraulic press mainly used for metal thick and thin sheet drawing, blanking, flanging, bendi... | |

| J23 series C frame Inclinable Press | Application: This J23 punch belongs to small stamping machinery and equipment, suitable for instruments, electronics, clocks, electrical appliance... |

Same products

| The Single Workstation Electrostatic Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | The single workstation electrostatic perforating machineis a professional cigarette paper static ... | |

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |