Waste web edge opener

Waste edge opener is a recycling machine especially designed for reprocessing nonwoven offcuts and waste raw materials. This equipment is mainly used for all kinds of non-woven fabric manufacturers. The waste edge of the product can be recycled and utilized with this product.

In the process of manufacturing and manufacturing non-woven fabrics, semi-finished products or finished trims are inevitably produced, which can be recycled into fibers by a waste edge opener. The opener does not damage the fiber, and waste edge can be reused in a certain proportion of the raw materials or used for other purposes.

Application:

reprocessing diverse nonwoven offcuts or waste and produce recycled fibers which can be used again for nonwoven products. It helps to save raw material and reduce production cost.

Features and Advantages:

1. Applicable for recycling diverse nonwovens offcuts and waste

2. High efficiency and less impairment of fiber

3.Compacted design and easy operation, available for online or offline running

4. Dynamic balanced components enable durable and good performance

Specifications:

|

Working width: |

500mm, 800mm, 1000mm |

|

Capacity: |

50 ~ 120kg/h |

Mechanical details:

1)Main cylinder covered with pins/card wire

2)Cylinder driven by individual motor and transmission, max. 1200rpm rotation speed

3)Separated feeding motor with diverse feeding rollers

4)Individual blower and conveying pipe

5)Complete safe protection

After more than 10 years of research and development, Sail already become one of leading maker of Waste edge opener machine in China. Due to the customized design, the update technology, the modern manufacturing process and the exllent after-sales service, Sail has shared a good reputation among our customers

Send product request

Other supplier products

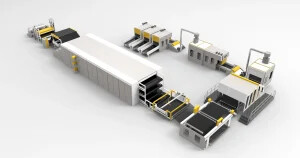

| Shoe material production line | Applications: For the production ofdiverse shoe material nonwoven involvingshoe lining, toe puff & countersand etc. | |

| Main opener(New) | Functionality & application:1.Handy pulling design to opening cover case, easy cleaning inside 2.Special air duct design largely reducing fiber... | |

| needle punching machine | needle punching machine(needle loom), as the first needle punching machine in work flow, needling stroke is higher than others, needle distribution... | |

| Nonwoven carpet and felt production line | Applications: For producing nonwoven carpet and felt fromPP, PET or other availablefibers. Usuallyit combineswithsome dipping, tentering or lamina... | |

| Single Cylinder Double Doffer Carding Machine | Sail nonwoven machinery Co.,Ltd is a professional manufacturer and suppliers that is concerned with the design, development and production ofSingle... |