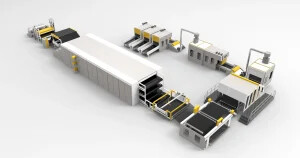

A.L –SS 1600mm Non Woven Machine Baby Diapers Fabric Pp Spunbond Nonwoven Making Machine

Product Features

|

Raw Material |

Polypropylene granule,Polypropylene powder ,Polypropylene recycle,additive |

|

Final Products Name |

PP Spun-bond Non-woven Fabric Making Production Line |

|

Fabric width |

1600mm(standard width after edge trimming) |

|

Spinning size |

|

|

Fines of filament |

spunbond system≤2.8den(1.8d-2.5d); |

|

Basic weight |

S: 10-200g/ m2 , SS: 15-200g/ m2 |

|

Machine speed |

10-250m/min |

|

Kinds of product |

SS spunbond nonwovens fabric S spunbond nonwovens fabric |

|

Machine size |

25m * width: 20m * height: 13m |

|

Electrical |

Transformer (actual need) : 500KVA (buyer's preparation) Power consumption: 450KW/ h |

Working Process:

1Feeding→2.Extruding&Melting→3.Filtering→4.Metering→5.Spinning→6.Cooling→7.Stretching→8.Web forming →9.Calender→10.online slitting →11.Winding →12.Offline Slitting&Winding(2sets)

Nonwoven fabric making machine supplier PP Nonwoven Machines are designed and manufactured in accordance with individual customer requirements, which are equivalent to Reifenhäuser Reicofil 3/4 types. Their possible area of application therefore is correspondingly wide.

PP Spunbond Nonwoven Fabric Making Machine manufacturers are featured with lower investment, compact construction, small area, simple production technology, simple operation, saving of labour and widely compatibility and so on.

In the Spunbond nonwoven process, polymers are transformed into endless filaments by melting and stretching, and then deposited on a wire mesh belt. The conversion of granulate into nonwoven takes place in a single production step.

We distinguish between three different types of spunbond lines: the one-, two- and three-beam lines. The biggest Rifference is the greater line speed and thus the extra output capacity that extra beams provide.

Why Choose AL NONWOVEN?

1:When you encounter problems, or your equipment needs to be upgraded, we can provide you with the most energy-efficient and reasonable budget solution

2:If you are a novice in the market, we will provide you with the most professional consulting services and guidance according to your expectations.

Make sure you do a test or trial before shipment so that you can witness real-time production and make necessary adjustments according to your market needs.

3:If you are planning to Increase your production scale, Let us know your requirements ( Intended product, Capacity, Density and Raw material)

We avail you the Production layout of the new line for your reference.

Our Service

Machinery complies to the highest standard in nonwoven industry creating by with individual outstanding components . supported by modern technology A.L designed for custom-built machinery and machinery offers an optimum solution for all customer requirements .

After sales service

We believe that only :Best Quality Machine With Innovative Ideas and Excellent After-sale Service “shall meet you special requirements

Send product request

Other supplier products

| ALBJB--1500mm Needle Punching Nonwoven Cleaning Cloth Scouring Pad Making Machine | Main Details: Weight (Chemical fiber): 200–500gsm Weight (Fiber + Glue): 250–550gsm Thickness: Max 20mm Finished Wi... | |

| AL- 2400mm SMS PP Melt-blown Fabric Making Production Machinery Line Non-woven Fabric Filters Machine | Product Description 1:Product name : AL-2400mm SMSPP SpunbondNonwoven FabricProduction Line 2:Manufacturer : AOLONG NONWOVEN (A.LNONWOVEN) 3:U... | |

| ALTGB---6500mm Geotextile Needle-punching High Speed Non Woven Fabric Making Machine | Technical Parameters Final Product Name: Geotextile Needle-punching High Speed Non Woven Fabric Making Machine Machine Width: 7000mm ... | |

| A.L – SS 1600mm Nonwoven Machine for Baby Diaper Fabric | Model: SS Spunbond PP Nonwoven Fabric Making Machine Manufacturer: DongYang Aolong Nonwoven Equipment Co., Ltd. This compact and efficient is opt... | |

| ALTG--PET Asphalt Geotextile High Way Needle Punching Nonwoven Fabric Production Line | The ALTG--PET Asphalt Geotextile High Way Needle Punching Nonwoven Fabric Production Line integrates the latest Nonwoven fabric production line tec... |