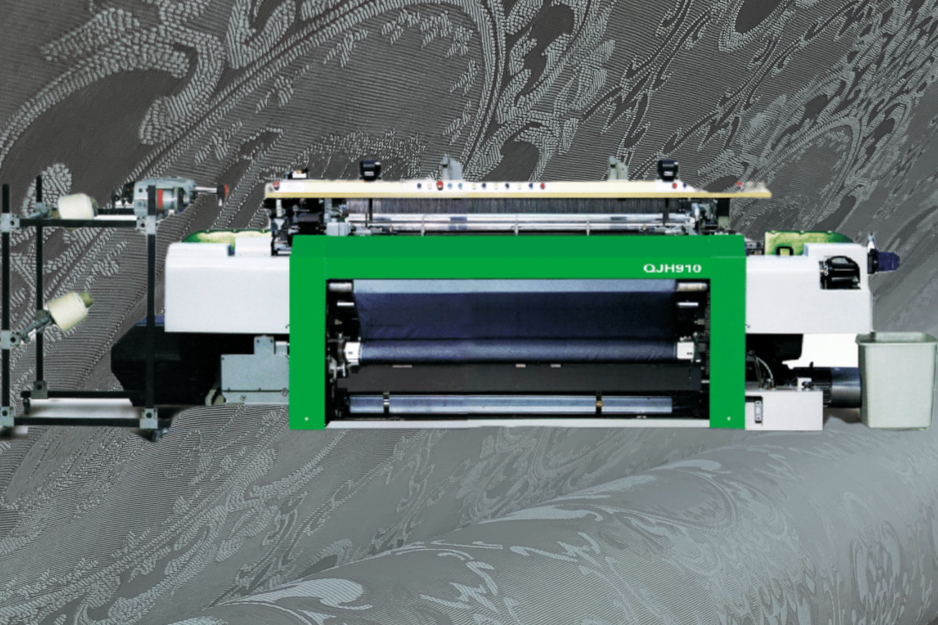

GA738-I Towel Loom

GA738-I Towel Loom

GA737 rapier towel loom,industrial weaving loomhas been released to the market for a long time a received good feedback from customers. This loom machine is known for features like stable function, cost performance, easy maintenance, long endurance and excellent fabric quality. The success of GA737 towel loom has lifted us to the leading position among all the weaving machine suppliers.

SALIENT FEATURES

Adoption of cam type terry pilling device to increase the softness of terry; the adjustment of terry height is very convenient.

The adoption of strengthened beat-up structure has increase the beating power, suitable for thick heavy terry fabrics.

Thicker weft beating shaft assures enough beating rigidity, making it possible to weave wide width terry towels above 280cm.

The optimized six-linkage weft insertion structure allows a softer and more rational weft insertion curve.

The two electromagnets controlled by process program on electronic system are able to weave both high and low terry.

The reed seat and other main parts made from aluminum alloy ensure a fast and stable performance of the loom.

TECHNICAL PARAMETERS

|

Width |

200cm(78”), 230cm(90”), 260cm(102”), 280cm(110”) |

|

Operation speed |

200cm 240rpm |

|

Yarn count |

cotton 7Ne~60Ne, wool 12Nm~100Nm, chemical fiber 100D~650D |

|

Take up |

rollerdiameterφ400mm |

|

Letoff |

Upper: positive electric let-off withbeam diameter φ600mm; ground:intermittentmechanical let-off, beam diameterφ600mm |

|

Shedding |

inhead typespring reversingmechanical dobby 24 shafts |

|

Colorselector |

6~8 colors |

|

Terry pilling |

Cam type movable reed terry pilling |

|

Terry height |

2~12 times stepless adjustment |

|

Weft stop |

Piezoelectric control |

|

Warp stop |

2 row electric warp stop |

|

Maindrive |

1.8KW~2.2KW |

|

Electronic control |

PLC |

|

Weight |

1900KG~2300KG |

|

Overall size |

4706*1936*2220(230CM/90”) |

Send product request

Other supplier products

| GA738-I Towel Loom | GA737 rapier towel loom is a kind of industrial weaving loom, and has been released to the market for a long time a received good feedback from cus... | |

| High Speed Rapier Loom | The application of high speed rapier loomis increasing due to wide adaptability, high speed, low energy-consumption and harmless to the environment... | |

| QJH810 Rapier Loom | QJH810 Rapier Loom QJH810 rapierauto loom machinehas been a best seller since the first machine was released to the market. It is an auto lo... | |

| Somet Looms | Our dozens of years experience and knowledge in the textile field have enabled us to supply all kinds of used somet rapier loomsand reconditioned m... | |

| Sulzer Looms | Our dozens of years experience and knowledge in the textile field have enabled us to supply all kinds of used textile machinery and reconditioned m... |

Same products

| RFAW20 High-Speed Assembly Winding Machine | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RFAW20 High-Speed Assembly Cone Winding Machine This product is a new assembly winder machine wi... | |

| RF310 Filament Fiber Two-For-One Twister | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RF310 Filament Fiber Two-For-One Twister Since the launch of the first set two for one twisterin... | |

| Through-Hot Air Bonding Non-woven Fabrics Production Line | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Through-Hot Air Bonding Non-woven Fabrics Production Line The Through-hot air through nonwoven f... | |

| Spun-Laced Non-woven Fabrics Production Line | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Spun-Laced Spunbond Non Woven Fabric Machine The spunlace linefrom RIFA is a cutting-edge system... | |

| Needle Punched Non-woven Fabrics Production Line | Seller: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Needle Punched Non Woven Needle Punching Machine The Needle Punched Non-woven Fabrics Production... |