Purified Water (PW) System

System adopts the latest processes such as reverse osmosis and EDI. A complete set of purified water treatment process has been designed in a targeted manner. The quality of purified water meets the requirements of the current USP, EP, JP and ChP for purified water.

Pretreatment is mainly used to remove particles that may damage the film and free chlorine. The reverse osmosis process is to separate and remove the soluble solids, organics, colloidal substances and bacteria in the water by using the semipermeable spiral membrane. The raw water is sent to and passes through the reverse osmosis membrane under a certain pressure. The water passes through the tiny pore diameter on the membrane and is collected to obtain pure water. Different impurities are concentrated in the intercepting liquid and discharged. RO can remove more than 96% of dissolved solids, more than 99% of organic matters and colloids, and almost 100% of bacteria from raw water.

EDI electromigration removal salt is to use the high voltage of electrodes at both ends of the module to move charged ions in water, and cooperate with ion exchange resin and selective resin membrane to accelerate the removal of ions, so as to achieve the purpose of water purification. During EDI desalination, ions are removed by ion exchange membrane under the action of electric field. At the same time, water molecules generate hydrogen ions and hydroxide ions under the action of electric field, which continuously regenerate the ion exchange resin to keep the ion exchange resin in the best state.

Degassing membranes are widely used to remove oxygen and carbon dioxide from water.

TYPES OF PURIFIED WATER SYSTEM

Water Pre-treatment

Based on the quality of different raw water, we are committed to providing customers with customized solutions. Modular design is adopted, with reasonable and compact structure, beautiful appearance a...

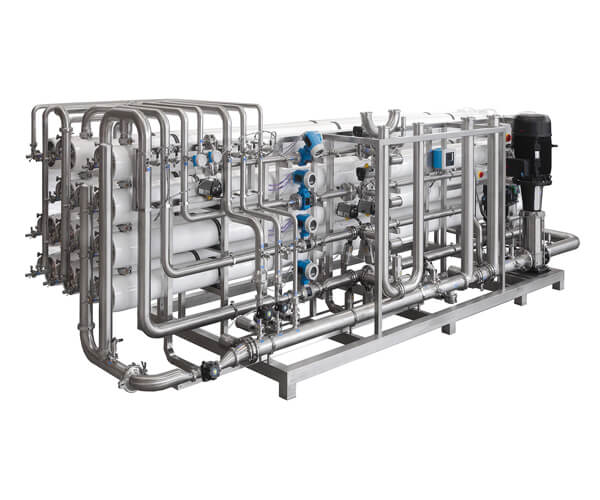

Pharmaceutical Reverse Osmosis System

With RO membrane separation technology as the core, it adopts automatic control, integrated design, modular installation, low energy consumption and small floor area. Double pipeline water supply and ...

FACTORS AFFECTING THE LIFE OF PURIFIED WATER SYSTEM

Due to the difference of user's raw water quality, the required purified water process plans will also be quite different (the system can achieve online pasteurization of pretreatment devices; reverse osmosis membranes and EDI modules can choose normal temperature and resistant pasteurization membranes according to requirements; pre-treatment devices can choose to add scale inhibitors or softeners according to requirements; users have high requirements for TOC indicators, and can choose UF (ultrafiltration) to remove TOC at the water production terminal). Based on years of design and practical experience, Biocell has not only been able to design purified water equipment more in line with users' needs, but also developed a purified water energy conservation and emission reduction process scheme with higher recovery rate for users.

WHY CHOOSE BIOCELL PURIFIED WATER SYSTEM?

01

Standardized and systematic parts are convenient for disassembly, maintenance and cleaning of equipment.

02

Automatic control is carried out through the terminal control system, and a humanized operation display system is configured to facilitate users to intuitively understand various data and adjust setting parameters.

03

The status of flushing, water shortage, full water, maintenance, etc. will be displayed on the purified water operation display system according to the actual situation, and the user will be reminded through the audible and visual alarm system.

04

The system has many unique functions, such as three-level password protection, fault shutdown alarm (manual reset is required), high and low pressure protection, automatic flushing, dual pipe water supply, etc.

We provide purified water system in pharmaceutical, pharmaceutical purified water systems, purified water system pharmaceutical, purified water system in pharmaceutical industry, purified water system in pharmaceuticaland etc. For more, contact us.

Send product request

Other supplier products

| CLEAN STEAM GENERATOR | The prototype of the clean steam generatoris a pure steam generator in the pharmaceutical industry. In structural design, it simplifies and weakens... | |

| ELECTRIC CLEAN STEAM GENERATOR | Clean steam generator using electric energy as heating source is referred to as electric heating clean steam generator. The steam generated after t... | |

| CLEAN STEAM GENERATOR | The prototype of the clean steam generatoris a pure steam generator in the pharmaceutical industry. In structural design, it simplifies and weakens... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | With RO membrane separation technology as the core, it adopts automatic control, integrated design, modular installation, low energy consumption an... | |

| REVERSE OSMOSIS PLANT | Separate the pure water from the solution containing solute with a semi permeable membrane that can only pass through water. At this time, the wate... |

Same products

| TOFFON bioproduct freeze dryer TF-LYO-2 | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | The LYO Biopharmaceutical Freeze Dryer is produced using standardized manufacturing processes, re... | |

| TOFFON freeze dryer TF-LYO-0.5 lyophilizer | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | LYO Bioproduct freeze dryer is a specialized machine used in biopharmaceuticals to preserve and ... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | Seller: Nanjing Biocell Environmental Technology Co., Ltd | PHARMACEUTICAL REVERSE OSMOSIS SYSTEM With RO membrane separation technology as the core, the re... | |

| SANITARY HEAT EXCHANGER | Seller: Nanjing Biocell Environmental Technology Co., Ltd | SANITARY HEAT EXCHANGER The wfi sanitary heat exchanger(sterile double tube plate heat exchanger... | |

| CLEAN STEAM GENERATOR | Seller: Nanjing Biocell Environmental Technology Co., Ltd | CLEAN STEAM GENERATORS The prototype of the clean steam generatorfor humidification is a pure st... |