UF Membrane Technology

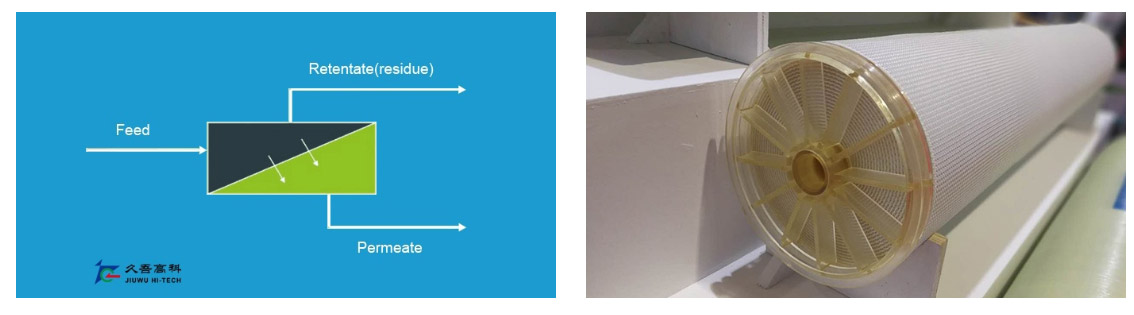

Ultrafiltration (UF) is a variety of membrane filtration in which forces, such as pressure or concentration gradients, cause separation through the semi-permeable membrane. High molecular weight suspended solids and solutes remain in the so-called retentate while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). The pore size of the ultrafiltration membrane is in the range of 0.01μm ~ 0.05μm, suitable for the separation, concentration and purification of macromolecules and small molecules.

Application of Ceramic ultrafiltration Membrane

UF technologycan be used to remove particulates and macromolecules from raw water to produce potable water. It has been used to replace the existing secondary (coagulation, flocculation, sedimentation) and tertiary filtration (sand filtration and chlorination) systems used in water treatment plants or as stand-alone systems in isolated areas with a growing population.

When treating water containing highly suspended solids, primary (screening, flotation and filtration) and some secondary treatments are often used as a pretreatment stage to incorporate ultrafiltration into the process.

When water recovery is simple, very little processing is often required. However, when more in-depth processing is required, industry standard procedures include the use of UF membrane technology, which means removing the physical solids from the water by passing them through a semipermeable membrane. With ultrafiltration, the solids are primarily captured by the filter and discarded.

Circulating water can also be used in a variety of industrial applications including water supply to boilers or cooling towers, pH control, cleaning equipment, hard beds and vehicles, fire fighting, rinsing or process water for manufacturing industrial lines, toilet flushing, dust control, construction activities Mix with concrete.

Ultrafiltration is often used to pre-treat surface water, seawater and bioprocessed municipal water upstream of reverse osmosis plants.

Industries that consume large amounts of water or discharge highly toxic wastewater may use ultrafiltration to recover water.

These include chemicals, steel, plastics and resins, paper and pulp, pharmaceutical and food and beverage industries, including soft drinks and canned foods, and electricity, water and wastewater treatment plants.

Ultrafiltration is used to recycle flow or add value to later products and more. In many cases ultrafiltration (UF) is used for prefiltration in reverse-osmosis plants to protect the reverse-osmosis process. Ultrafiltration is an effective means of reducing the silt density index of water and removing particulates that can foul reverse osmosis membranes.

Features of Ultrafiltration Membrane

Ultrafiltration processes are preferred over traditional treatment methods for the following reasons:

No chemicals required (aside from cleaning)

Constant product quality regardless of feed quality

Compact plant size

Capable of exceeding regulatory standards of water quality, achieving 90-100% pathogen removal.

JIANGSU JIUWU HI-TECH CO. LTD.,founded in 1997, focus on producing ceramic membrane filtersfor many years. And JIUWU HI-TECH has become a leading company in the membrane separation industry. We sincerely invite and welcome people from all around the world to invest and create more values together.

Send product request

Other supplier products

| Titanium Membrane Module | Titanium MembraneModule JIUWUcompany designs the module with Titanium material. The main application of titanium module is brine filtration. ... | |

| SS Membrane Module | The SS ceramic membranemodule is designed by different applications. Stainless steel could be used as the material of module/housing, that is, ss m... | |

| Organic Membrane | The organic membraneis a material having a selective separation function, and when there is a driving force on both sides of the membrane (such as ... | |

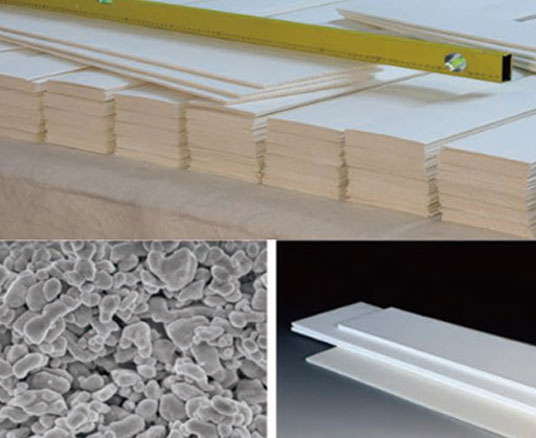

| Flat Sheet Ceramic Membrane | As a leading Chinese Ceramic Membrane factory, JIUWUHI-TECH has been focusing on the R&D of advanced ceramic membrane technology. The ceramic ... | |

| Ceramic Membrane | Ceramic membranes (Porous Ceramic Membrane& tubular ceramic membrane) are available for microfiltration, ultrafiltration and nanofiltration as ... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |