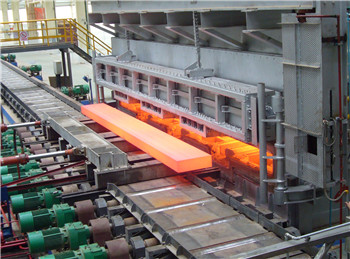

aluminum walking beam type heating furnace

This furnace are made up by feeding device, furnace body, walking beam system, door, lifting device, combustion system, combustion supporting system, purging system, waste-heat utilization device, unloading device, hydraulic system, industrial television monitoring system, lubricating system and automatic control system.

Billets are delivered at the charging door by the feeding roller. According to the different billet size, billets can be delivered on the walking beam inside furnace by pusher or cantilever roller inside furnace. The walking beam or walking bottom which loads billet moves in according with rectangle track generally, billets go through different temperature zones for heating, the heated billets go out from furnace by drawer or cantilever roller to be rolled.

There are pre-heating, heating and soaking zone 3 area of heating, the rated temperature is 1050℃, the difference inside the furnace is ±5℃.

Safety control system: before ignition, the furnace will be blowed clear in case of explosion.

The walking beam consists of horizontal walking beam, lifting walking beam and bevel pathway.

Send product request

Other supplier products

| Skew rolling mill for steel ball | Steel Ball Skew Rolling Machine is specially designed for the grinding steel balls of different materials such as medium carbon steel, alloy steel ... | |

| Aluminum UBC System chips recycling machine | Aluminum chips line specially for chips processing. Capacity can be 1 tons to 2 tons per hour processing. Energy saving is the most feature and the... | |

| Transformer HV foil Winding Machine | The HV foil winding machine is used to wind high voltage coils for cast resin encapsulated transformers with Al or Cu foil strips. The individual A... | |

| rock wool board and strips production | Rock/mineral/stone/slag wool is a kind of insulation material mainly used in purpose of fire proof, heat insulation and sound insulation. The rock ... | |

| aluminum strip foil hot rolling line | Technical performance of aluminum hot rolling mill: Slab thickness range from 150mm to 290mm Slab width range from 500mm to 850mm Strip width... |