Cage Making Machine Factory

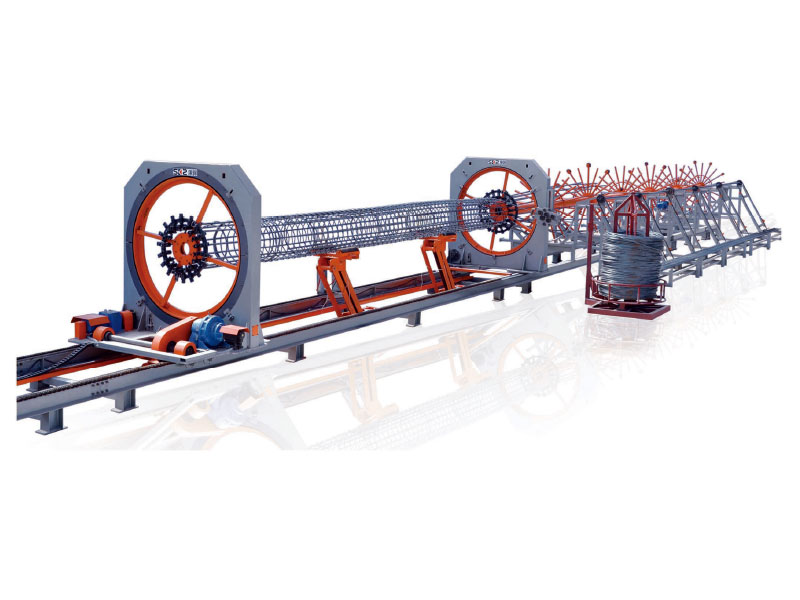

The construction of the steel cage is the significant part of the basic bridge construction.In the past of the traditional construction, reinforcement cage uses the manual rolling or the manual welding, except low efficiency,The main shortcoming is that the quality of the cage is poor and the equipment size is not standard which deeply affects the construction period and quality of project. The Steel Cage Welding Machine, Which combines steel straightening, bending forming with rolling welding, makesbacially realized mechanization and automation, reduces the process time and the deviation between various links, greatly improving the quality and efficiency of the steel cage forming, so as to creates a good economic and social benefits for the construction units and become the future development direction of reinforced cage.

Highlights

It is of highautomatic, fast processing speed .Compared with the ordinary manual molding,it is 3 ~ 4 timesmore thantraditional manual production

The processing qualityof is stable and reliable: with mechanical operations, the main reinforcementand the pitch of the winding is uniformand with high accuracy. Because of the mechanical rotation, the plate reinforcement works closely with the main bar wrapping. Adding stirrup afterforming, the uniform diametercan ensure the concentricity of the reinforcement cage.The product quality meets the standard requirements completely. The supervision of mechanized processing of steel reinforcement cage basically implements the “exemption”.

The processing cost is greatly reduced,whencomplete the same amount of work, mechanical production can save 3/4of the manpower

Workers fatigue strength is greatly reduced, due to the mechanical operation, workers play a supporting role. Construction image is greatly improved.

Stirrup does not needoverlapping, compared with the manual operation, itsaves 1% of the materials, which reduces the construction cost.Due to the uniform distribution of main barin its circumference, it is very convenientwhen more than one of and saves installation time

parameter

|

Model |

KZ1500X |

KZ2000X |

KZ2500X |

|

Cage diameter (mm) |

φ500-1360 |

φ500-1860 |

φ500-2360 |

|

Cage length (m) |

2-12 |

2-12 |

2-12 |

|

Max weight of reinforcement cages (KG) |

≤4500 |

≤6000 |

≤8000 |

|

Diameter of main bar (mm) |

φ16-32 |

φ16-32 |

φ16-32 |

|

Spiral diameter (mm) |

φ6-12 |

φ6-12 |

φ6-12 |

|

Spiral spacing (mm) |

50-500 |

50-500 |

50-500 |

|

Labeled electric power (kw) |

18 |

21 |

25 |

|

Walking speed (m/min) |

|||

|

Rotating speed (r/min) |

2-3 |

2-3 |

2-3 |

|

Over 0imension (L*W*H)(mm) |

27,000x4500x2700 |

27,000x5000x3200 |

27,000x5500x3700 |

Feeding → inserting main bar → fixing→overlaping spiral→ welding → normal welding→ stop welding→ cutting spiral→ Separate fixed disk → loose tendons →separating movable disk → unloadingcage→ lowering electricsupport →homingmovable disk

technical solutions

Staffing

Under normal circumstances, 5 to 6 personcan work.Specific distribution is as follows:

Preparationand feedingmaterials:2 people

Roll welding:1~2people

strengthening hoop: 2people

The Specific number of peope should be based on the sizeandthe modelof the steel cage.

Production efficiency

1500mmpile cage: two classes, can processe 300-400 meters / stand (about 20 tons)one day.

When Welding a 12-metre ,thegeneral loading and unloading time is approximately 15-20 minutes, normal welding time is approximately 18-25 minutes (spaced 120), sotne conprehensivetime is 30-45 minutes,the speed can be greatly improved after skilled.(generally,the weight ofa steel cage with diameter of 1.5meters and length of 12meters isabout 800 kg)

The efficiency of forming steelcage is related to the number of the main bars, the diameter of the reinforcement, the pitch of the woundand the operation of the workers.

With different project, the design of reinforcement cage will be changed (such as the number or diameterof main reinforcement ), it can adapt to different engineering needsby changing the template and the catheter.

Send product request

Other supplier products

| HIGH SPEED STRAIGHTENING & CUTTING MACHINE | HIGH SPEED STRAIGHTENING & CUTTING MACHINE,Double Wire Straightening Cutting Machine Manufacturer,Double Wire Straightening Cutting Machine... | |

| rebar shear-line Factory | This cutting machine is used to cut high-tensile steel bars of big diameter into expected-length pieces which will be then sorted and stored, al... | |

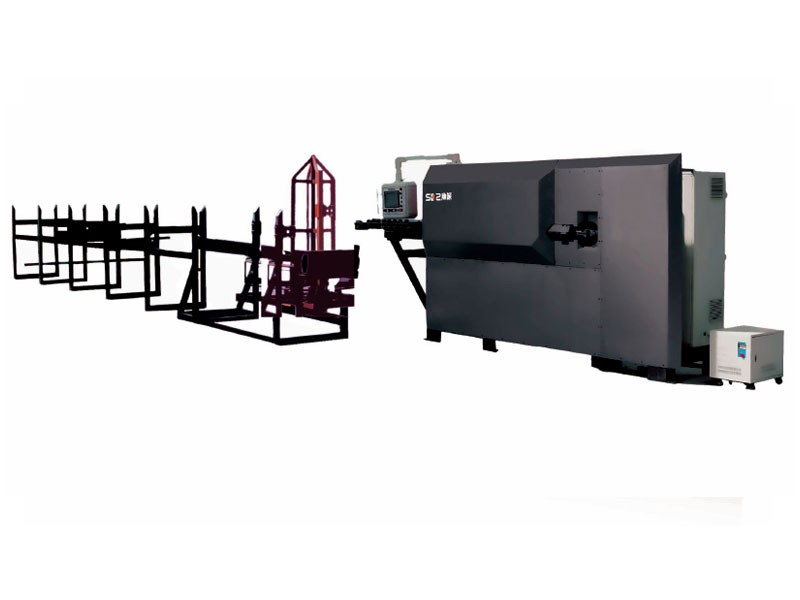

| Stirrup Bender Factory | Stirrup bender is designed for complete straightening,bending and cutting on one machine. Coil is the prefer raw material choice, but SKZ is the... | |

| HIGH SPEED STRAIGHTENING & CUTTING MACHINE | HIGH SPEED STRAIGHTENING & CUTTING MACHINE use the high speed rotating spinner to make straightening. This machine make straight bar from co... | |

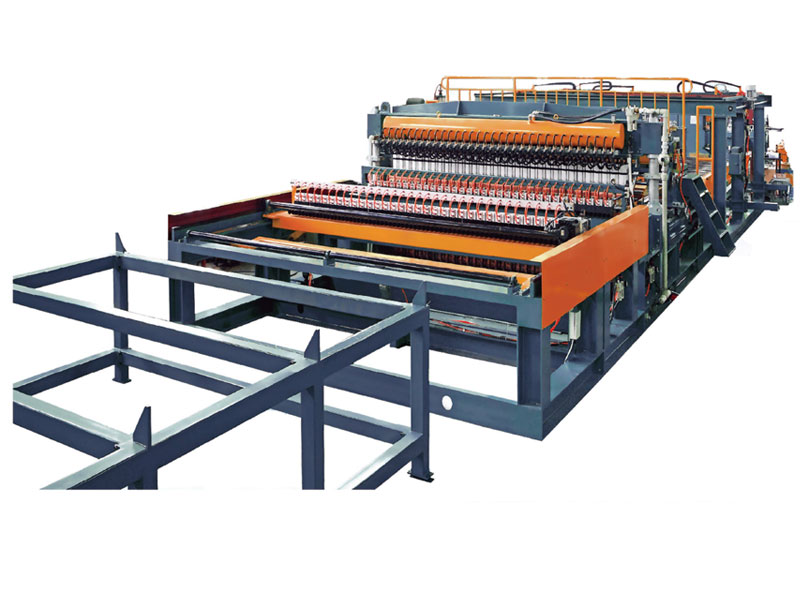

| Reasonable layout Mesh Welding Machine | SKZM3300 series wire mesh welding machine is complete equipment for welding wire mesh, which is manufactured by SKZ based on learning foreign ad... |