Investment Casting

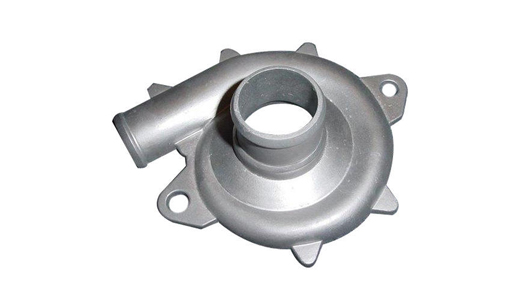

Investment casting, also called the lost-wax casting process, is actually an ancient metal casting technology with a history of over 6,000 years. It generally refers to the mold made by meltable materials (such as wax, plastic, etc.) in very accurate dimensions. The mold is applied to several layers of refractory coating, then heat it to create a solid and hard shell over the mold. The further step is to heat it at a very high temperature, so as to melt the inner mold so that let the fire-resistant shell left. All these processes together we call them "molding", it describes the basic method to make the shell that we desired for the next casting works.

After making the shell, the next casting works is similar to normal sand casting. Pouring the melted metal into the shell, wait until the casting part cooling down. Then break the shell to acquire the finished part.

The Advantages of Investment Casting

Manufacture of Investment Casting

The first process of investment casting production is the manufacture of the investment casting mold, which is used to form the model of the cavity in the refractory shell, so to obtain castings with high dimensional accuracy and surface finish. In addition, the performance of the investment casting mold itself should make the subsequent processes such as shell making as easy as possible. In order to get the above high-quality requirements of the investment casting mold, in addition to a good press (press molten die mold), but also must choose the appropriate investment casting materials (referred to as mold material) and reasonable mold making process.

Most of the production uses pressure to press the paste mold material into the pressed shape to make the investment casting mold. Before pressing the casting mold, a thin layer of the parting agent is applied to the surface of the mold so that the molten mold can be removed from the mold. When pressing a wax-based mold, the parting agent can be divided into machine oil, turpentine, etc.; when pressing a resin-based mold, a mixture of sesame oil and alcohol or silicone oil is often used as a parting agent. The thinner the parting agent layer, the better, so that the investment casting mold can better replicate the surface of the pressed mold and improve the surface finish of the molten mold. There are three methods of pressing the investment casting mold, plunger pressurization, pneumatic pressurization, and piston pressurization.

Description of Investment Casting

Investment casting is also called lost wax casting when the wax is used for the mold. Investment casting usually refers to a casting scheme in which to shape by fusible material, and the shape surface is coated with several layers of refractory material to make the shell. Then the shape is melted out of the shell, so as to obtain the investment casting without parting surface, and the casting scheme can be filled with sand after high-temperature roasting. Because the investment casting mold is widely made of wax material, investment casting is often called lost wax casting.

The types of alloys that can be produced by invest casting process include carbon steel, alloy steel, heat-resistant alloys, stainless steel, precision alloys, permanent magnet alloys, bearing alloys, copper alloys, aluminum alloys, titanium alloys, and ductile iron.

The shape of the investment casting mold is generally more complex, which can be cast out of the minimum diameter of the hole up to 0.5mm. The minimum wall thickness of the casting is 0.3mm. In the manufacturing process, some parts are originally made from a combination of several parts, by changing the structure of the parts, design to a whole part and cast directly from the investment casting mold, in order to save processing time and metal material consumption, so that the structure of the parts more reasonable.

Rayforce Manufacture is a private investment casting factory, we provide metal casting china, investment casting technology, investment casting systems, direct investment casting, apa itu investment casting, and etc. Want to know investment casting priceor buy investment casting? Please contact us.

Send product request

Other supplier products

| Brass,Bronze,Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Semi-Solid Die Casting | Based on the theory of stir cast invented by Mr. D.B. Spencer and M.C.Flemings, the semisolid die castingtechnic has been further developed and app... | |

| Low Pressure Die Casting | The low pressure die casting is to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting par... | |

| Low Pressure Die Casting | The low pressure die casting is to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting par... | |

| Sand Casting | Sand casting chinais the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroallo... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |