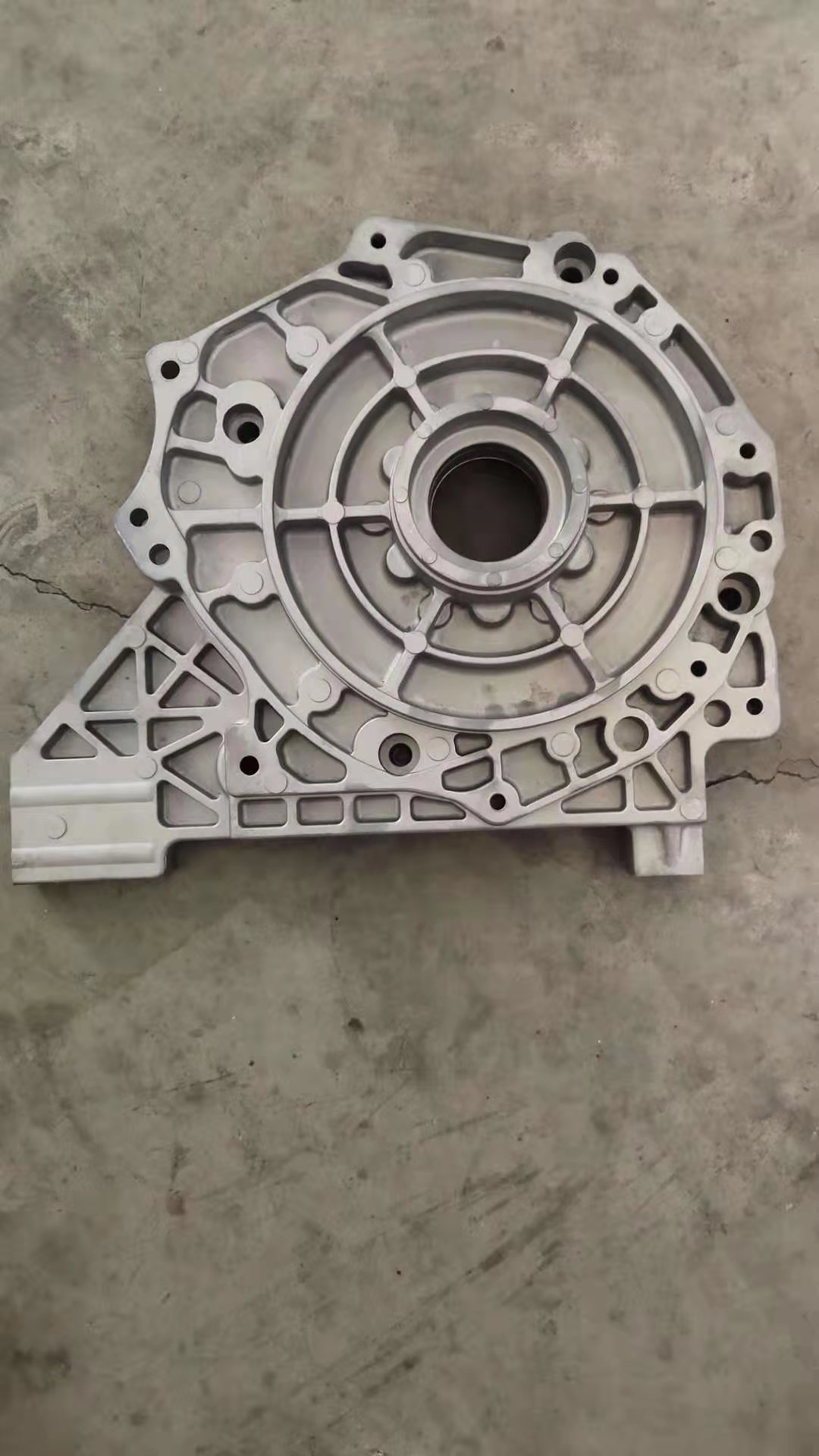

Aluminum Casting

Aluminum is a lightweight metal with silvery-white color. Because of its chemical features, aluminum never exists in the metallic form in nature. But aluminum compounds are abundant, with the development of modern extraction technology, now aluminum becomes one of the most widely applicable non-ferrous metals. The casting process is one of the major methods applied to form the aluminum into the required product.

The basic method of aluminum casting molding is relatively similar to iron castings, sand casting, and die casting. There're other techniques such as lost foam and lost investment casting methods. And these methods also are used by the foundry to apply to some specific demands, but only in fewer cases.

Rayforce casting manufacturing company uses state-of-the-art equipment to offer the aluminum casting product with great flexibility and competitive price for our clients. The production method by green sand and lost investment casting is able to make all size and complexity model products, with beautiful surface quality, and fast delivery from prototype to finished product.

Features of Manufacturing Aluminium Die Casting Products

High pressure and high speed filling die-casting aluminum type are the two main characteristics of making aluminum die casting products. It is commonly used pressure injection ratio from thousands to tens of thousands of kPa, even up to 2 × 105 kPa. The filling speed is about 10 ~ 50m/s. Sometimes even up to 100m/s or more. The filling time of injection die casting is very short, generally in the range of 0.01~0.2s.

With strict inspection, Rayforce provides high-quality products for customers at a reasonable aluminum die casting price.

Advantages of Aluminum Casting Alloys

Aluminum casting alloys have some unique advantages compared with other castings, such as beautiful, lightweight, and corrosion resistance, which makes them widely favored by users, especially since the lightweight of automobiles. Aluminum casting alloys have been widely used in the automotive industry. The density of aluminum cast alloy is smaller than cast iron and cast steel, while the specific strength is higher.

Aluminum casting alloys have many advantages, which makes them become the development direction of the casting industry and one of the most popular casting products for customers purchasing. In the future, with the progress of aluminum casting alloys technology in aluminum casting foundry, it will show itself on a bigger stage.

Rayforce Manufacture is a private aluminum die casting factory,we provide metal casting china,low pressure aluminum casting, green sand for casting aluminum, aluminum sand casting foundry, aluminum gravity die castingand etc. Want to know aluminium die casting priceor more? Please contact us.

There are many metal casting companies, but we are one of the best choices for you.

Send product request

Other supplier products

| Die casting | High precision die castinginvolves 3 key elements: the die casting machine, the mold, and the alloy materials, and the die casting could be describ... | |

| Agriculture & Vehicle | Rayforce's metal casting can be applied to plough, tractor part, soil cultivation, planting, harvesting, hay making, animal feeding machine, etc. ... | |

| Brass, Bronze, Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Sodium Silicate Sand Casting | Sodium silicate castingis soluble in water in various amounts. A more common name for sodium silicate is water glass, which is used in iron or stee... | |

| Semi-Solid Die Casting | Based on the theory of stir cast invented by Mr. D.B. Spencer and M.C.Flemings, the semi-solid die casting technic has been further developed and a... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |