LOST-FOAM CASTING

As a lost foam castingsupplier, HQ provides lost-foam casting for the customers who need mass production of repeat products. Our professional team will help you from the design step, please feel free to contact us.

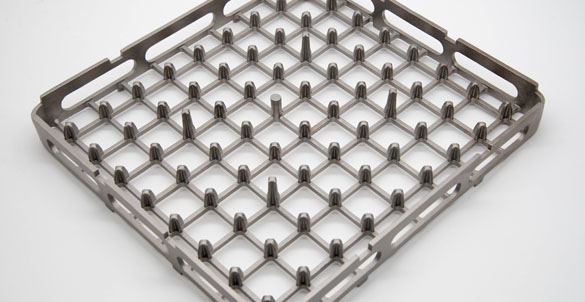

LOST-FOAM CASTING PRODUCTS

LOST FOAM CASTING PROCESS

After we receive the drawings and samples, HQ staff will follow the procedure below to ensure the customer successfully get the products they ordered.

Drawings or measure samples

Evaluation by the technical team

Decide manufacturing process

Confirm with customer

Mold designing and making

Casting

Inspection and Testing

Confirm with custome

Mass production

Monitoring and update progress

Finished products inspection

Shipment

LOST FOAM CASTING SUPPLIESINFORMATION

|

About 500KG |

|

|

About 10G |

|

|

LEAD TIME |

Mold designing and manufacturing 15~20 days Casting 25~35 days |

LOST-FOAM CASTING FAQS

Yes, with drawings, our engineering team could understand the products better and calculate the costs more accurately. However, we also accept samples for measuring and redesigning. Please contact us for more details.

Yes, as a professional investment casting factory in China, HQ not only cooperates with large enterprises but also is happy to help small business and DIY enthusiasts. Please contact us with products details for the minimum order numbers.

If you want to know more kinds of custom precision machined parts, please visit our website.

Send product request

Other supplier products

| TITANIUM FLAT WASHERS | TITANIUM FLAT WASHERS These beautiful titanium flat washers, titanium fender washersare made from Titanium Alloy and Available for multiple applic... | |

| COPPER CNC MACHINING | Copper CNC Machining As a leading machining factory, HQ is dedicated to providing high-quality machining products. We routinely supply Copper CNC a... | |

| METAL CASTING PRODUCTS | METAL CASTING PRODUCTS HQ accumulated years of experience in Metal casting products and accumulated technical know-how to help customers choose th... | |

| TITANIUM SHEET | TITANIUM FOIL SHEET As a leading titanium supplier, HQ always provide the best titanium sheets/plate with a reasonable price. We follow a strict p... | |

| TITANIUM WHEEL STUD | TITANIUM WHEEL STUD HQ Titanium Studs are manufactured with aerospace-grade forged titanium that ensures highly reliable usage These lightweight w... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |