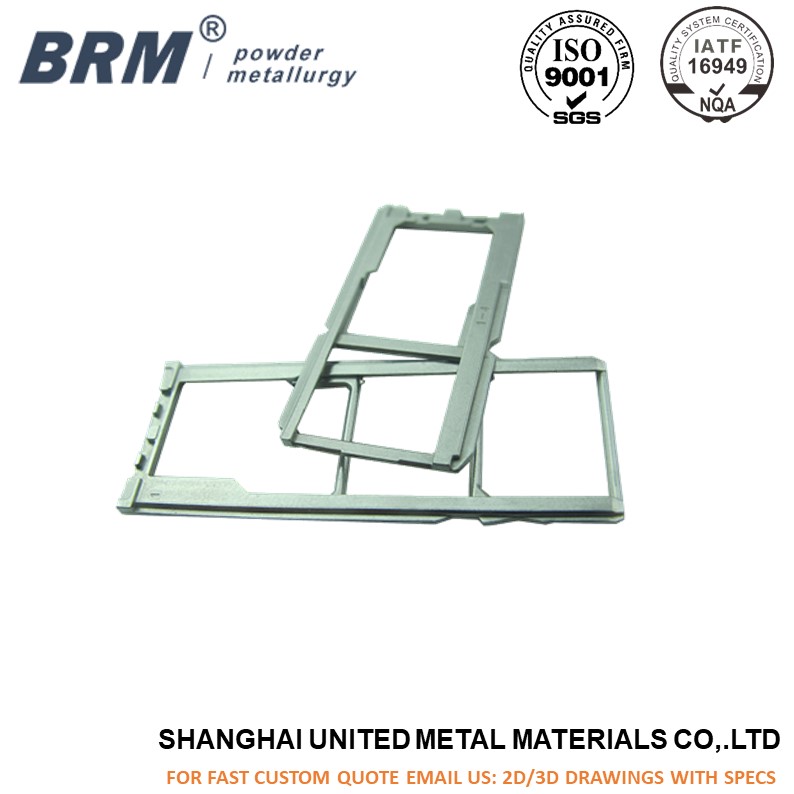

Mim SIM Card Holder Made In China

Why Choose BRM

1. Over 20 years experience of metal injection molding

2. Certification of IATF16949, ISO9001, SGS, RoHS etc.

3. 5000m² factory area with Daily output over 2000000pcs

4.One-stop serive of Designing, Manufacturing and Finishing

5. Tooling 25 days, Sampling15 days.

BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20 years. We have helped thousand of our customers with one-stop service from Designing, Manufacturing &Finishing by use of different metalworking process like

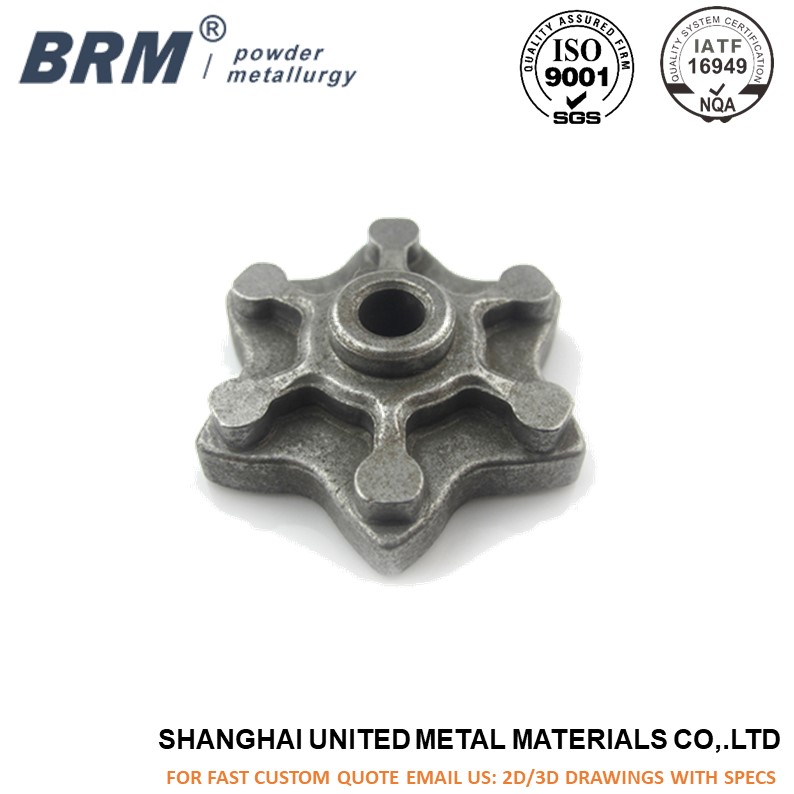

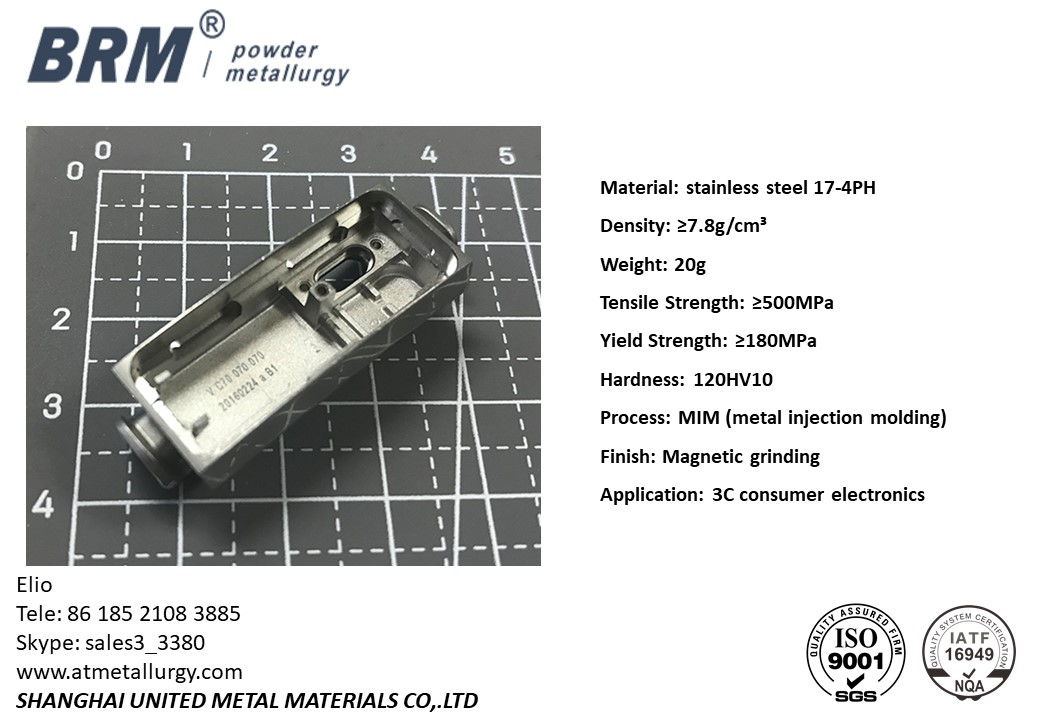

Metal injection molding

PM (press sintered)

Precision casting

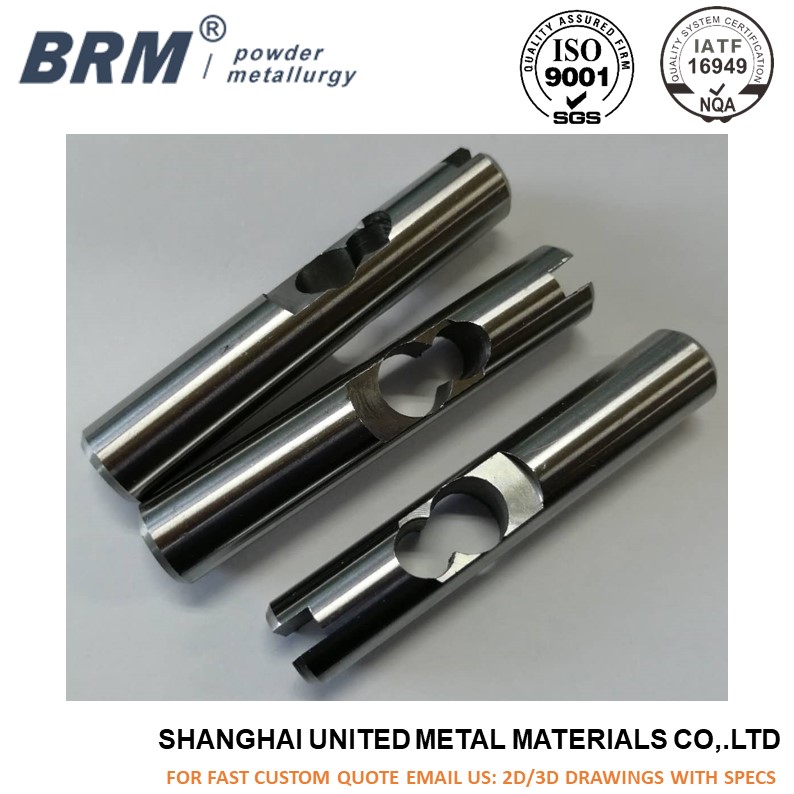

CNC &Machining

Certification IAFT16949, SGS, RoHS, ISO9001, ISO14001 and ISO18001. Also inspection report before delivery will be forwarded to control the quality.

Applicable materials we can do include stainless steel, low alloy steel, tool steel, tungsten alloy, soft magnetic alloy and so on. Our mim products can apply in many fileds especially Military, Automotive, 3C consumer electronics, Medical, Tools and Machinery.

Send product request

Other supplier products

| PM Motorcycle Shift Cam | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... | |

| Watch Case Mim 17-4PH Sintered Parts | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advance... | |

| MIM4140 steel selector button with blackening surface treatment | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... | |

| Precision CNC machining platen of rotor for automotive transmission parts | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... | |

| Watch Buckle Mim Sintered Stainless Steel | Why Choose BRM 1. Over 20 years experience of metal injection molding 2. Certification of IATF16949, ISO9001, SGS, RoHS etc. 3. 5000m² factor... |

Same products

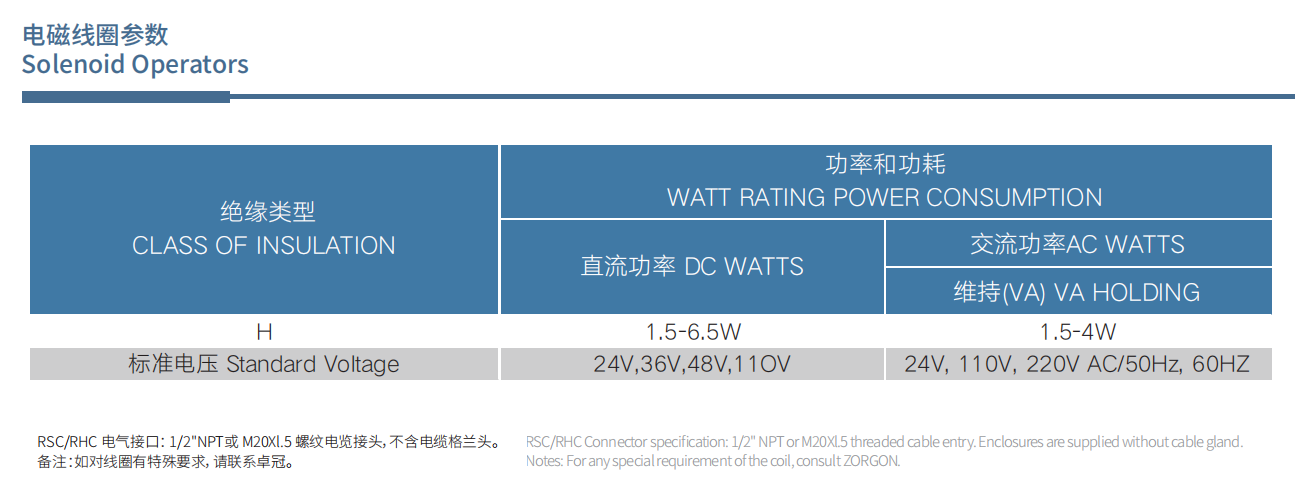

| SERIES 151 solenoid valve | Seller: ZORGON | 151 series solenoid valve, solenoid valve are suitable for use in conjunction with pneumatic cont... | |

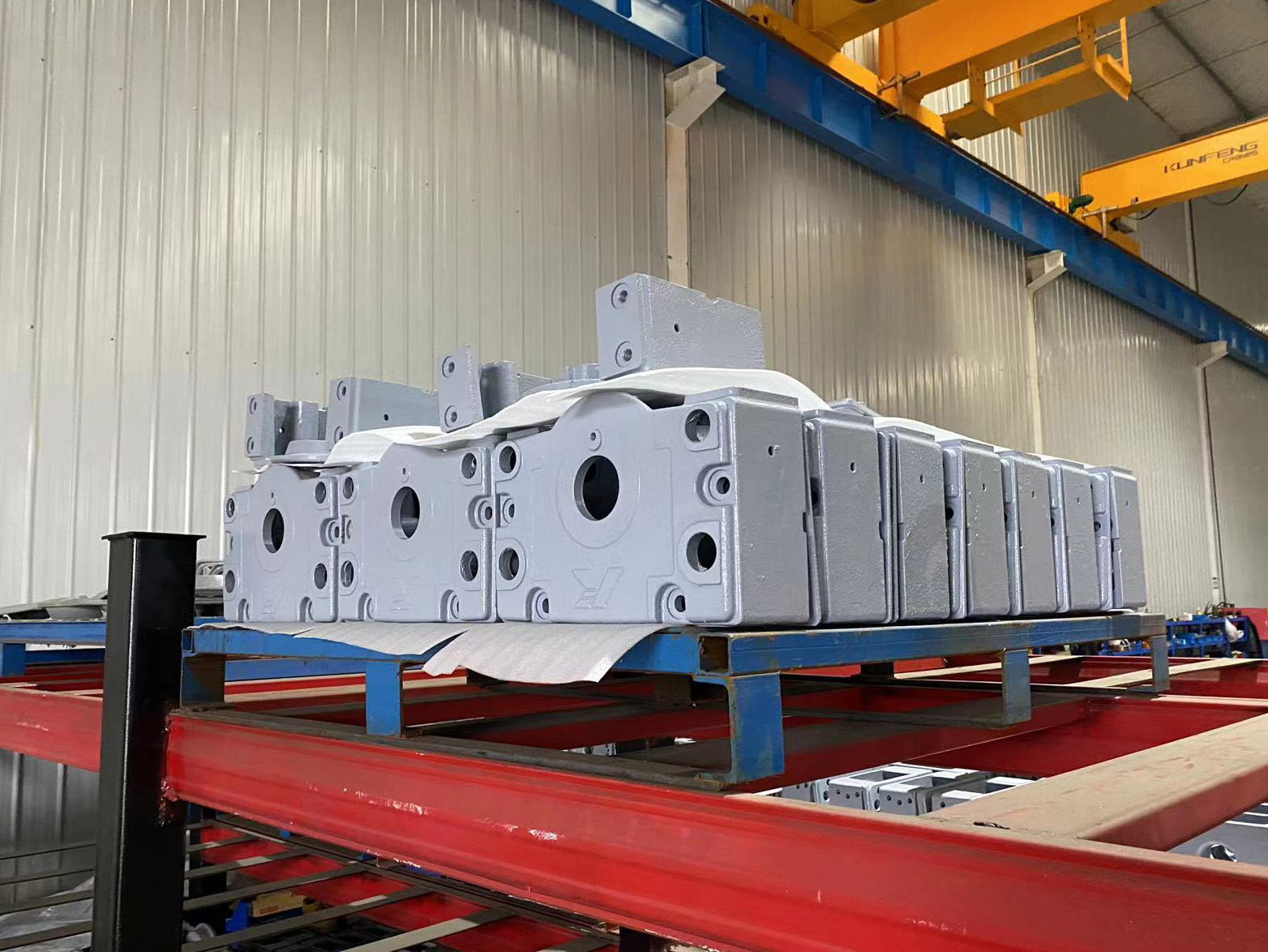

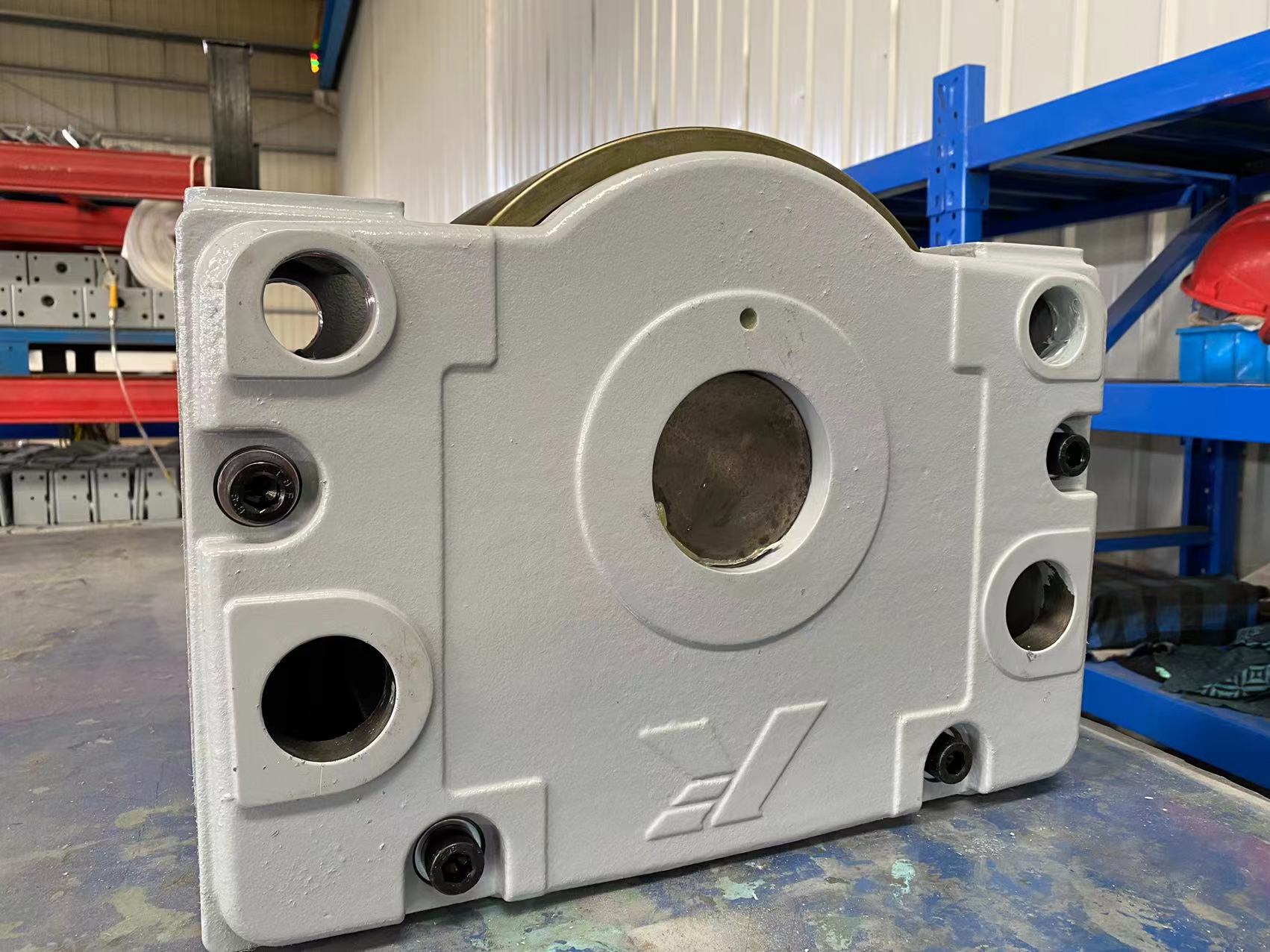

| Wheel Block Drive System with Gear Motor for Crane | Seller: KunFeng Heavy Industry (Suzhou) co., LTD. (KF CRANE) | A complete driven wheel system includes the wheels, electric AC induction brake motor, gearbox, e... | |

| DRSA Wheel Block System | Seller: KunFeng Heavy Industry (Suzhou) co., LTD. (KF CRANE) | KUNFENG® DRSA Wheel Block System features large load capacity with compact dimension, wheel d... | |

| CNC machining precision steel parts | Seller: BRM metal injection molding | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | Seller: BRM metal injection molding | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |