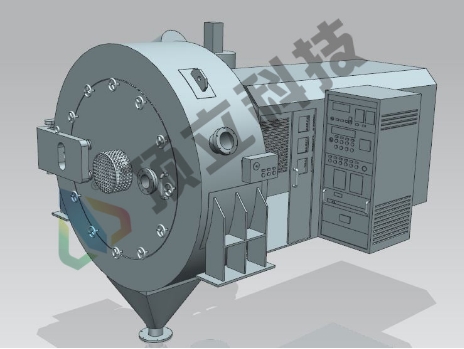

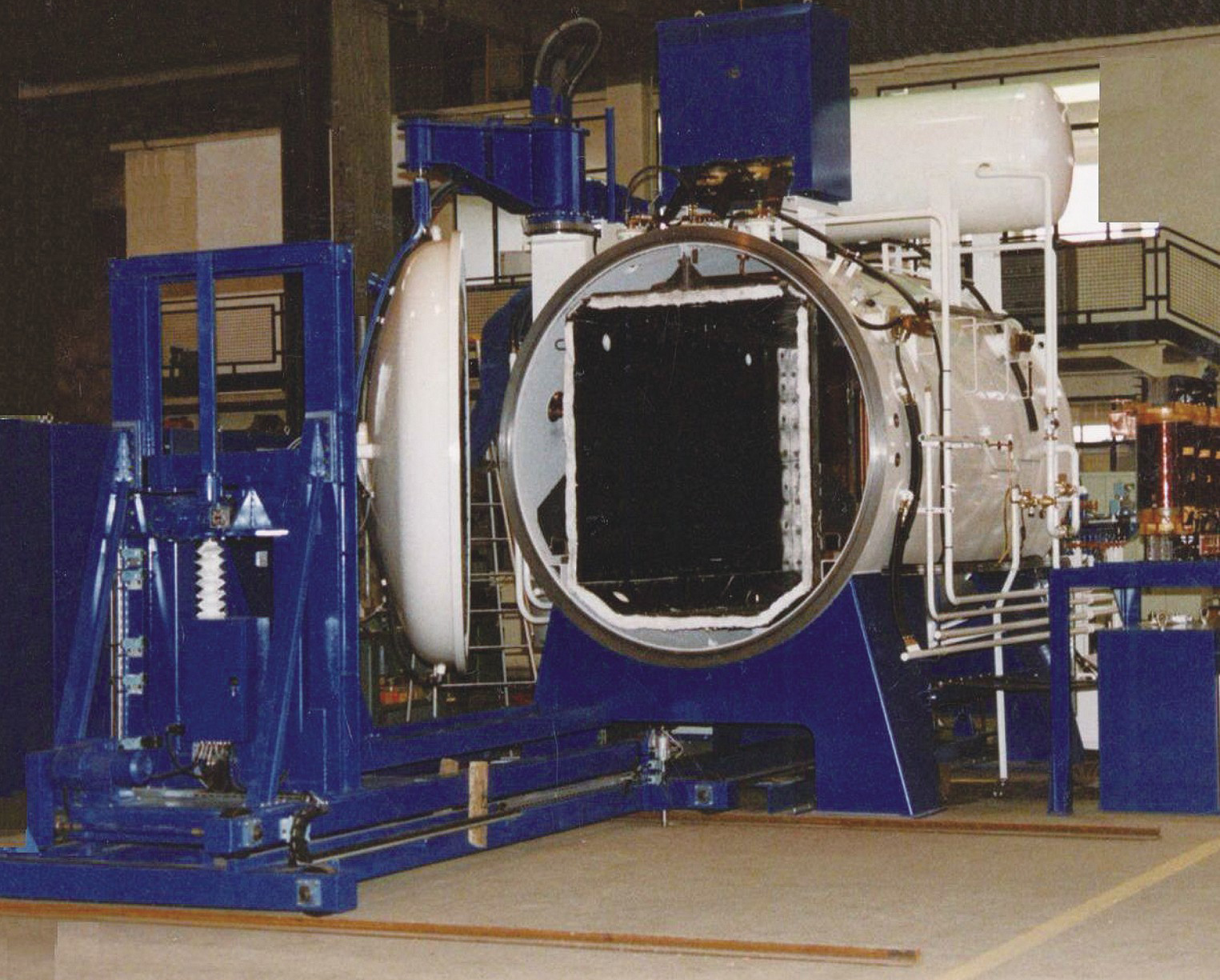

Plasma Rotating Electrode Atomization Equipment

Description

Plasma rotating electrode atomization equipment processes metal or alloy powders with good sphericity, fewer defects, uniform and narrow particle size distribution, low impurity content, low oxygen content and low growth, which is applied for aerospace materials and addictive manufacture of special metal-based powder material.

Advantages

1.On base of powder technology, Dingli is focus on the research of new generation plasma rotating electrode process and equipment manufacturing.

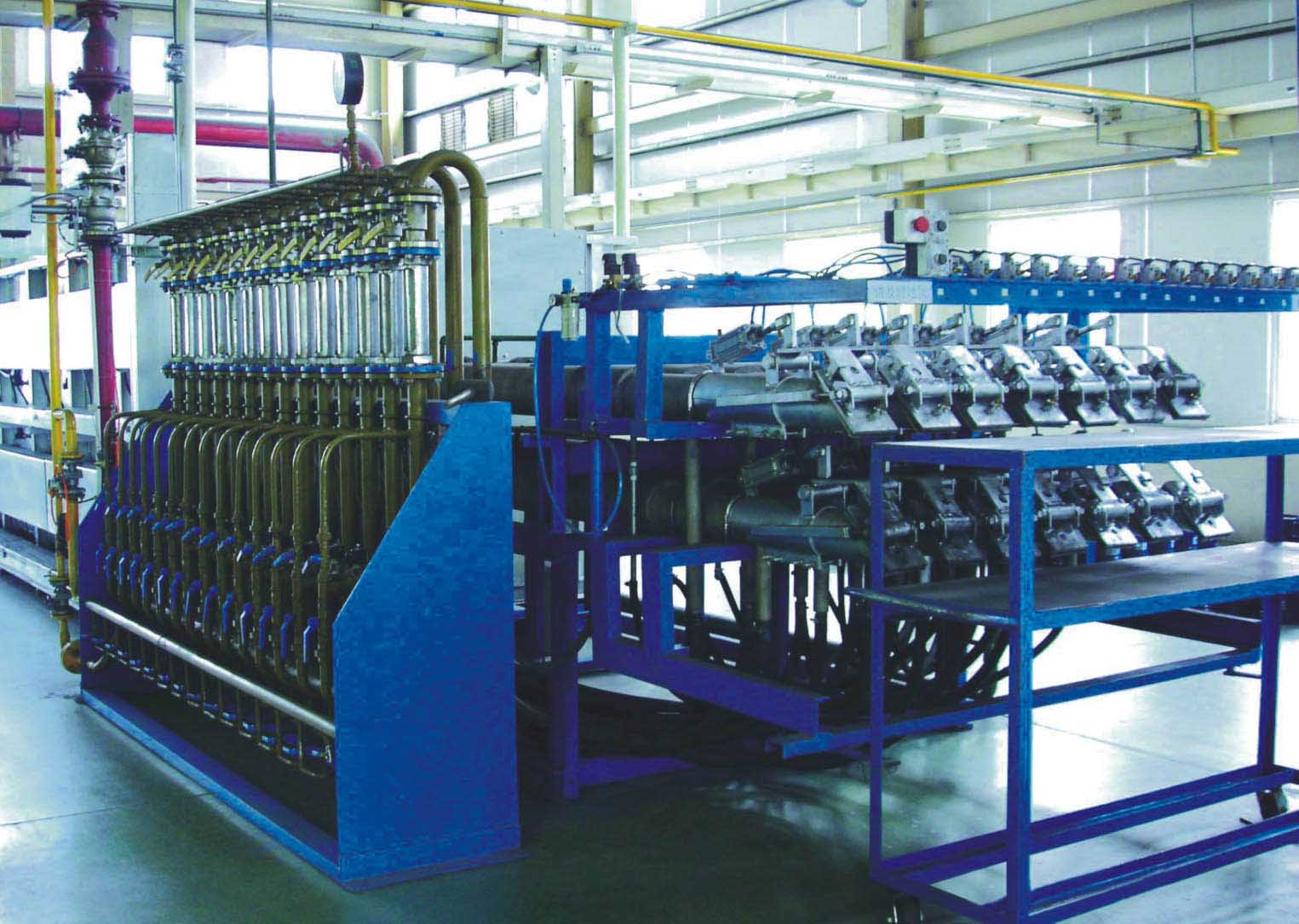

2. The company develop independent intellectual property rights in equipment technology and rotating atomization technology from continuous feed, sealing, auto arcing as well as information feedback, intelligent control.

3. There are 7 to 8 patents in the dynamic seal ring floating in oil-free, water-cooled centrifugal brush, tripod, high-speed rotary gas seal technology, bar connection technology, high-speed rotating vibration cancellation technology, conical furnace, high-current flexible couplings and other aspects, which enhance plasma rotating electrode atomization technology and equipment level.

Send product request

Other supplier products

| Gas Pressure Sintering Furnace | Gas pressure sintering furnace is mainly used for vacuum sintering and pressure sintering of Sic, Si3N4 and other ceramic parts. | |

| Intelligent Vacuum Heat Treatment Production Line | Vacuum heat-treatment intelligent product line includes almost all the heat treatment processes for different material parts. The product line can ... | |

| 18-Tube Automatic Reduction Furnace | DescriptionMulti-tube furnace is mainly used for metal powder (like tungsten, moly, etc) reduction.Technical Features1. Multiple tube heating guara... | |

| High Vacuum Aluminum Brazing Furnace | DescriptionHigh vacuum aluminum brazing furnace is applied for vacuum brazing of materials like heat exchanger, air condition evaporator, condenser... | |

| Horizontal Double Chamber Vacuum Carburizing Furnace | Horizontal vacuum carburizing furnace is applied for the carburizing and quenching after carburzing of materials like structure steel (20CrMnTi, 12... |

Same products

| Lifting Beams Adjustable Lifting Beam | Seller: Hebei Connect Trading Co.,Ltd | Structure: I Beam For Lifting type and streamline form. Working Load Limit: 2 Ton to 50 Ton A... | |

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... |