Jumbo-Bag Filling Machine with Pallet Magazine Jumbo Bag Packing Machine jumbo bag filler for carbon black powder 1 tonner bagger for flour baler for wood saving 1 ton bagger for MAGNETITE POWDER 1 to

Jumbo-Bag Filling Machine with Pallet Magazine Jumbo Bag Packing Machinejumbo bag filler for carbon black powder 1 tonner bagger for flour baler for wood saving 1 ton bagger for MAGNETITE POWDER 1 ton bag (FIBC) filling system for corn 1t Jumbo bag filling machine for ammonium nitrate 1000kg Jumbo Bag Packing Machine FIBC Bag Discharger Big Bag Discharger jumbo bag packing units 无锡航一机械有限公司 WUXI HY MACHINERY CO., LTD.

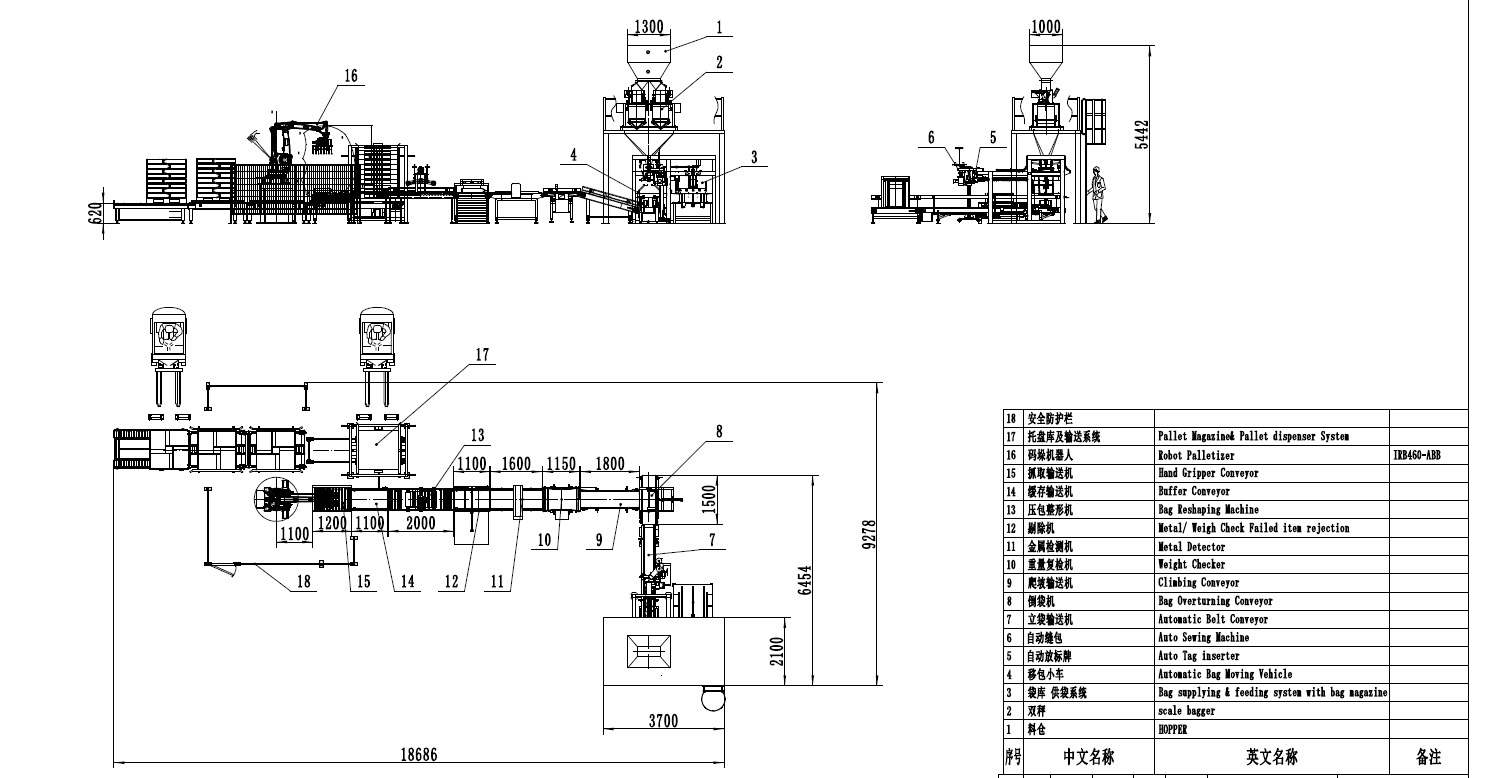

Super Sack Filler Jumbo Bag Filling Machine, FIBC Bag Filler bulk bag filler JUMBO BAG PACKING MACHINE ONE TON BAGGING UNIT, FIBC Bagger, Jumbo bag filling machine,Bulk bag filling machines,Bulk bag loader,big bag filling machine,super sack filler Jumbo Bag Filling Machine, Super Sack Filling Line, one ton packing machine, big-bags filling weighing packing machine for ton bags, big bag packing machine for 1000kg jumbo bags 无锡航一机械有限公司 自动吨袋包装秤大袋吨袋包装机 Produced by WUXI HY MACHINERY CO., LTD full automatic bagging palletizing and wrapping system Fully Automatic Packing System Palletizing Line

Application

This is big bag filling station, Jumbo Bag Filling Machine, Super Sack Filler, bulk bag filler, big bag filling machine, FIIBC bag filler produced by Wuxi HY Machinery Co., Ltd. It's used for quantitative weighing packaging solid materials into big bags such as 500kg, 1000kg, 2000kg, etc., and the main component parts as following: the feeding mechanism, weighing mechanism, pneumatic actuators, rail section, folder bag section, dust-removing section, electric control system, etc.. It's production packing line suitable for weighing packing many kinds of materials into 500~2000kg jumbo bag including food, protein, flour, grains, agricultural products, feed, talc powder, calcium chloride, fertilizers, urea, building materials, cement, mortar, big bag filling station for Calcium carbonate powder, engineering plastics, monosodium glutamate, starch, coal powder, cobblestone, paste block, polyethylene, PVC addition, Polyester flakes, potassium chloride, potassium sulfide, ammonium sulphide, sulphur, zinc oxide, oxalic acid and other powder, granules, tablets or mixtures. ( e.g., granular feed, corn, rice, paddy, wheat and granular seeds, feed, food, medicine, chemical raw materials, etc. ). And it can be designed to match with automatic pallet feeding system.

It's optional to install loading conveyors, dust collector, automatic pallet dispenser system, coding machine, pallet wrapping machine, etc. to make the complete production line. Produced by Wuxi HY Machinery Co., Ltd.

Technical Parameter

Model: LCS-HYT

Accuracy: 0.2%

Weighing scope: 500-2000kg per bag, customized design.

Capacity: 10~40bags/hr, depending on the materials features and bags supplying speed.

Power Supply: AC110-240V/220-600V, 50/60Hz, 1/3P, customized made as per local electrical system

Power: 1.1~5 kW, depends on the materials (powder or granules)

Compressed Air : 0.4~0.6 MPa ( 0.35m3/min)

Self Weight: 1100~1500kg, subject to the real machine.

Dimension of the Conveyor: W1500*L4000mm(2.5m + 1.5m), customized.

Send product request

Other supplier products

All supplier productsSame products

| Full-automatic Spring Packaging Machine ZF-TH700 | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | Seller: Hangzhou siseyin Technology Co., Ltd | ||

| Sticker equipment | Seller: Hangzhou siseyin Technology Co., Ltd | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |