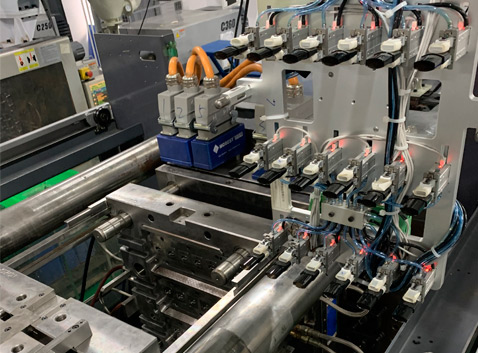

Trial-Run Molding

A mould trialis a process by which a new mould is optimised in order to produce the desired products as efficiently as possible. This makes it one of the most important aspects of injection moulding.

DETAIL OF TRIAL MOLDING

Trial Molding Process

Set barrel temperature according to recommendations from the material supplier. Middle of recommended in front and lower end of recommended in back, if don’t have date sheet, reference from mold flow report. Record actual melt temp with air shot method. If the customer is to attend the trial, the material data sheet should be printed and present at the machine.

Set mould temperature to the middle of recommended temp span, if don’t have date sheet, reference from mold flow report. Also, make sure the actual mould temp is right during production.

Set clamping force according to Moldflow report, or max clamp of customer specified machine.

Set holding pressure to 0 at first.

Increase the shot size gradually until parts are ~90% full. Check cavity variation. If more than 7% cavity variation, write down in page and mark as the issue needs to improve

Increase the shot size until parts are 100% full, parts can be sink but not short. If parts have flash, burns or air traps, write down in paper comment as the issue needs to fix

Set shot size to 97% full, should be done including an estimated holding time.

Set holding pressure to ½ the actual injection pressure.

Runoff samples and mark them trial number and date, this is very important information for us to find which samples are from the previous trial time, quantity according to customer requirements if parts are ok. 1 balance shot and 2-3 runners should always be sent together with the samples.

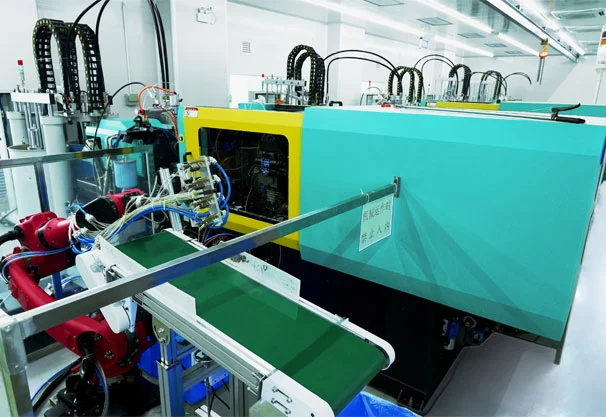

As a precision injection molding manufacturer, we will do our best to meet all the needs of clients.

Send product request

Other supplier products

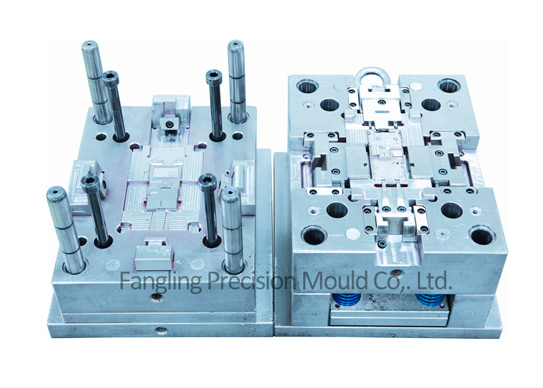

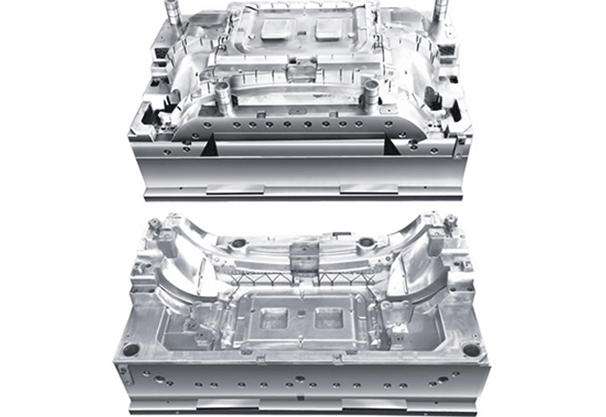

| PRECISION PLASTIC INJECTION MOLDS/TOOLS | When it comes to plastic injection mold parts, precise moulds and precision equipment are required for precision molding or PIM. Among the topics c... | |

| Mold Assembly | When designing plastic injection moulded parts to be used in conjunction with other parts, the assembly must be considered. There are several assem... | |

| Stamping Mold Parts | Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press ... | |

| Wire Cutting Mold Parts | We are an unparalleled name in offering a wide gamut of wire cutting parts. These spare parts are amongst the most desirable and reliable products ... | |

| Final Plastic Products | We stock a line of plastic moulded productsincluding well over 200 components for dialysis. We continue to innovate with new product designs and di... |

Same products

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | Seller: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Seller: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Seller: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Seller: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |