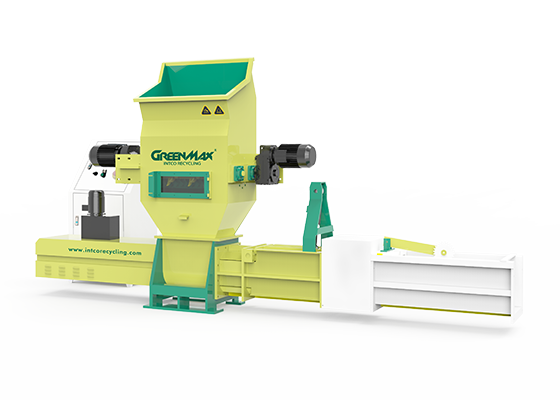

Single-Station One-step Extrusion Molding Machine for Mixed Waste Plastic Films

The fully automatic one-step plastic film extrusion equipmentis our company's patented product. Fully automatic film extrusion equipment: mainly used for processing various mixed plastic film materials to produce products, mixed waste plastic films: household garbage film, plastic film greenhouse film, paper mill waste plastic film, Marine garbage film, Tetra Pak, food packaging film, etc., after cleaning, drying and processing, do not need to classify, do not need to granulate and directly use plastic film materials to make various products you need.

Specifications of Single-Station One-step Recycled Plastic Extrusion Molding Machine

|

Item No. |

Frequency (pcs/min) |

Press pressure |

Output |

Total Power |

Product size (length * width) |

Outside dimension |

Weight |

|

(KG/H) |

(KW) |

(L*W*H) |

(Ton) |

||||

|

GWJZD-1 |

315 |

100-150 |

300*300 |

6000*1460*3500 |

25 |

||

|

GWJZD-2 |

2月3日 |

1500 |

350-450 |

250 |

1500*1300 |

10000*5400*6000 |

85 |

|

GWJZD-3 |

2000 |

450-550 |

108 |

1600*1400 |

14000*5500*7000 |

120 |

Features and Advantages of Single-Station One-step Recycled Plastic Extrusion Molding Machine

It can recycle the mixture of different plastic film, rigid plastics and the pellet.

Our equipment adopts low pressure injection molding, so the exhaust effect is better, and the raw material doesn’t need very low moisture content.

We use patented or special barrels and screws to ensure sufficient plasticization and dispersion of materials.

We use hydraulic press machine to offer huge pressure for making high density and strength products.

Our equipment doesn’t require high-quality material, so the material cost is very low.

Our equipment is not demanding on the mold, and the mold cost is low.

We adopt core technology to make product weight error really small.

We adopt PLC control system to realize high automation, less labor requirement and high efficiency.

How Does Single-Station One-step Recycled Plastic Extrusion Molding Machine Works

The one-step equipment adopts a (patented) variable diameter screw, and the feeding section adopts a large diameter, which is convenient for the feeding of the film material; the screw forced feeding is used on the top, so that the film material always has a downward force, and has the function of super force reversal . With screw forced feeding and variable diameter screw, the continuity and accuracy of feeding and the required output are ensured. Through the precise design of the equipment, it is ensured that the weight of each pallet is basically the same, and the error does not exceed 0.1 kg. The whole line is controlled by PLC and has a high degree of automation. One production line can be completed by only one person.

We can offer sorts of plastic recycling equipmentfor sale, if you want to buy high quality plastic washing recycling machine, please leave us a message.

Send product request

Other supplier products

| Mixed Plastic Recycling Extrusion & Injection Molding Machine | The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment ... | |

| Single-Station One-step Recycled Plastic Extrusion Molding Machine | The fully automatic one-step film extrusion equipmentis our company's patented product. Fully automatic film one-step extrusion molding equipment: ... | |

| PET Pelletizing Machine | PETPelletizing Machine Sale The pet flakes pelleting machinecan achieve ideal PET viscosity without a complex pre-crystallization drying system.... | |

| Double-Station Two-Step Extrusion Molding Machine for Mixed Waste Hard Plastics | The double-station recycled plastic extruder is twice as efficient as the single-station, and the price of recycled plastic extrusion machine is 3/... | |

| Single Screw Plastic Waste Granulator | The single screw plastic granulatoris mainly suitable for extrusion and granulation of raw materials, which is not only clean or single with stable... |

Same products

| PET bottle recycling machine And Squeezer POSEIDON C900 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| GREENMAX PET bottle recycling machine P-C350 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| PET bottle recycling machine And Squeezer POSEIDON C200 | Seller: Intco Recycling GREENMAX | PET bottle recycling machine Poseidon series specializes in de-watering and compacting beverage b... | |

| GreenMax Foam Compactor Z-C100 | Seller: Intco Recycling GREENMAX | GreenMax Zeus C100 foam compactor isspecialized in waste foam recycling by extruding foam based o... | |

| GREENMAX EPS crusher for beads | Seller: Intco Recycling GREENMAX | GREENMAX EPS beads crusher is a recycling equipment, especially for recycling EPS/polystyrene. Di... |