Open Type Rubber Mixing Mill

1).The chill cast shell and the inner part of the roll can be poured separately. Thus different composition of iron for the shell and for the inner part can be chosen freely according to different requirements.

2).The thickness and the hardness of the chill cast shell can be controlled more precisely and uniformly.

3).The molten iron is condensed under the centrifugal force.The surface of the shell is free from porosity, sand hole, slag inclusion, or other casting defects.

4).When the roll is made by ordinary gravity pouring process, there is always a layer of mottled iron formed between the white iron(chill cast iron) and the gray cast iron. When drilled roll is used, this mottled cast iron layer always makes the drilling very dificule. When the roll is made by centrifugal pouring process, there is no mottled iron layer formed at all. The mottled iron layer problem no longer exists. The drilling can be done easily and precisely.

5).When proper materials are used and centrifugal pouring process is adopted. the hardness of the chill cast shell can hold as high as HS 74+/-2.The tensile strength of the roll can reach as high as 250 MPa. The working life of the roll made by centrifugal pouring process would be three to five times the working life of the rolls made by ordinary gravity pouring process.

Send product request

Other supplier products

| Rubber Cutting Machine | 1. Rubber cutting machine is used to cut natural rubber, synthetic rubber, rubber products and other plastic materials, simple structure, convenien... | |

| Rubber Crushing Mill Machine | Rubber Crushing Mill: groove on rear roller, used for raw rubber crushing before plastication. | |

| Rubber Crushing Mill Machine | Rubber Crushing Mill: groove on rear roller, used for raw rubber crushing before plastication. | |

| Large Plate Vulcanizer | 1)The machine is in frame structure with below pressing form (upwards). 2)Under the working hydraulic pressure, the embolism ascends to make hot pl... | |

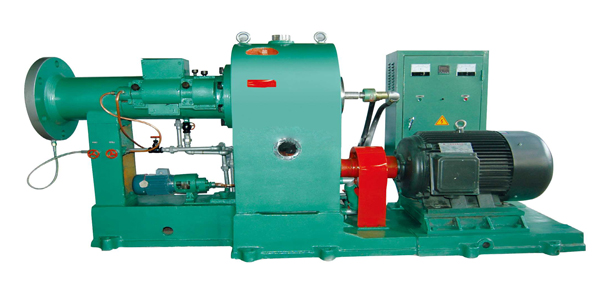

| Rubber Extruding Machine | The extruding machine is uses in squeezing out the tread protector, the tire tube, the rubber tube and each kind of rubber strip rubber machinery, ... |

Same products

| Air Cooling 500kg/h PP PE Granules Machine for Plastic Recyling Plant | Seller: Plastic Recycling Machines & Solutions - Haorui Machinery | Function of PP PE Pelletizing Line A PP PE pelletizing line is responsible for transforming wast... | |

| JYYJ-H-V6 polyurethane foam spraying machine | Seller: 824810 | -Voltage:380V 50HZ -Heating Power:22KW-26KW -OUTPUT:2-10kg/Min -MAX OUTPUT (Mpa):36Mpa -Matri... | |

| JYYJ-Q200D polyurethane foam spraying machine | Seller: 824810 | -Voltage:380V 50HZ -Heating Power:11KW -OUTPUT:2-10kg/Min -MAX OUTPUT (Mpa):25Mpa -Matrial A:... | |

| Pentamethylene High Pressure PU Foam Machine /High Pressure Cyclopentane Polyurethane Machine | Seller: 824810 | Features:1. The metering is accurate, and the high-precision metering device is adopted, and the ... | |

| High pressure polyurethane foam injection machine | Seller: 824810 | Product Features of High Pressure PU Machine:1. Material injection mixing head can freely move fo... |