Magnetic Liner

All supplier products

For the conventional , ore pulp and grinding media wear and impact the liner directly while in operation, along with the electrochemical corrosion at the same time.

or the conventional ball mill liner, ore pulp and grinding media wear and impact the liner directly while in operation, along with the electrochemical corrosion at the same time. But for the magnetic liner, the working principle is quite different: these magnetic liners are arranged alternately in the ball mill to form a strong magnetic field, the magnetic liner attracts a layer of broken or small steel balls and ferromagnetic minerals to the liner surface when in operation, thus forming a natural dynamic protective layer. In initial period, the workers can add broken balls or iron powder to help form the protective layer, which often can be 20~30mm. So the service life of the magnetic liner is extended greatly, is generally 10 times even dozens of times of high manganese steel liner.

Material:

Material and production process of the protective metal casing:

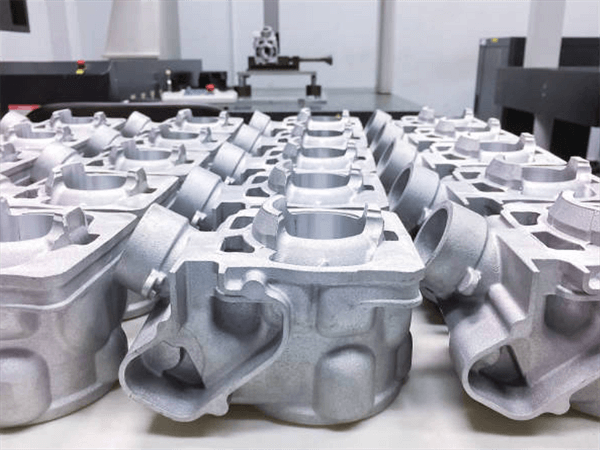

Our company’s researchers developed a special non-magnetic material, which consists of military special alloy metal and some necessary elements. This type material has many great properties:such as wear-resistant, acid-proof, Alkali-resistant,corrosion resistance and excellent non-magnetic permeability. All these properties enable the formation of sufficient strength and thickness of protective layer . By using EPC casting process, we produce metal casing with neat appearance and precise size, so the contact surface of the cylinder and magnetic liner can up to more than 95%.

Send product request

Other supplier products

| Ball Mill Liner | Three characteristics: With scientific and reasonable formulation of alloy elements, the high manganese steel liner is multivariate micro-alloyi... | |

| High Chrome Grinding Ball | Size of casting iron ball: Small size: Ø10mm--Ø40mm; Medium size: Ø50mm--Ø90mm; Big size: Ø100mm--&Oslas... | |

| Forged Grinding Ball | According to the present situation of 9.754.88m SAG mill, grid plate hole 60mm, and we recommended your company changed ball diameter from the or... | |

| Crusher Hammer | Matters Needing Attention Rong Mao is a leading manufacturer of , crusher hammer in China. | |

| High Manganese Steel Ball Mill Liner | High manganese steel ball mill liner is used to protect the direct impact and wear of grinding ball and materials. At the same time, the differen... |

Same products

| Custom Gravity Cast Service | Seller: Neway Precision Works Ltd | Explore the differences between gravity casting and other casting methods to determine the best... | |

| Metal Injection Molding Service for MIM Parts Manufacturing | Seller: Neway Precision Works Ltd | Neway is a top-notch metal injection molding service provider for custom MIM parts. Get your ... | |

| THE 24th CHINA(GUANGZHOU) INTERNATIONAL DIE CASTING,FOUNDRY & INDUSTRIAL FURNACE EXHIBITION | Seller: GUANGZHOU JULANG EXHIBITION DESIGN CO., LTD | 2024China(Guangzhou)Int’l Metal & Metallurgy Exhibition THE 24th CHINA... | |

| Hydraulic Steering Control Units | Seller: Hebei Golden-hammer forgings co., ltd | The hydraulic steering gear is a hydraulic power steering type between the steering wheel and the... | |

| Hydraulic Motor | Seller: Hebei Golden-hammer forgings co., ltd | The hydraulic motor is an actuator of the hydraulic system that converts the liquid pressure ener... |