Hydraulic Motor

Hydraulic Motor

The hydraulic motor is an actuator of the hydraulic system that converts the liquid pressure energy which provided by the hydraulic pump into the mechanical energy (torque and speed) of its output shaft. Liquid is the medium that transmits force and motion.

The hydraulic pump and the hydraulic cylinder motorare reversible hydraulic components, and the input of the working fluid to any one of the hydraulic pumps can make it into a hydraulic cylinder motor condition; conversely, when the main shaft of the hydraulic cylinder motor is external When the torque is driven to rotate, it can also be changed to the hydraulic pump working condition. Because they have the same basic structural elements - a closed and periodically variable volume and a corresponding oil distribution mechanism. However, due to the different working conditions of hydraulic cylinder motors and hydraulic pumps, their performance requirements are different, so there are still many differences between hydraulic motors and hydraulic pumps of the same type. First of all, the hydraulic cylinder motor should be able to be positive and reverse, thus requiring its internal structure to be symmetrical; the speed range of the hydraulic motor needs to be large enough, especially for its minimum stable speed. Therefore, it usually uses a rolling bearing or a static pressure sliding bearing; secondly, the hydraulic cylinder motor does not have to have self-priming capability because it operates under the input pressure oil condition, but requires a certain initial sealing property to provide the necessary starting torque.

As one of the hydraulic motor suppliers, we not only provide below standard hydraulic cylinder motors, but also produce hydraulic cylinder motors according to customer’s requirement, just show us the request!

Types of Hydraulic Cylinder Motors

According to its structure type, hydraulic cylinder motor can be divided into gear type, blade type, plunger type and other types. According to the rated speed of the hydraulic motor is divided into high speed and low speed two categories. The rated speed is higher than 500r/min and the rated speed is lower than 500r/min. The basic types of high speed hydraulic cylinder motors are gear type, screw type, blade type and axial plunger type.

Vane motors

Gear motors

Gerotor motors

Axial plunger motors

Radial piston motors

Staffa hydraulic cylinder motor

Calzoni hydraulic cylinder motor

Why Select Hydraulic Cylinder Motor

From the point of view of energy conversion, the hydraulic pump and the hydraulic motor are the hydraulic cylinder motor component that work in a reversible way. The input of working liquid into any hydraulic pump can make it become the hydraulic cylinder motor working condition. On the contrary, when the spindle of the hydraulic cylinder motor is driven by the external torque to rotate, it can also become a hydraulic pump working condition.Because they have the same basic structural elements--a closed and periodic volume and the corresponding oil distribution mechanism. However, because the working conditions of hydraulic cylinder motors and hydraulic pumps are different, their performance requirements are not the same, so between the same type of hydraulic motors and hydraulic pumps, there are still many differences.

First of all, the hydraulic cylinder motor should be able to forward and reverse, so its internal structure is required to be symmetrical. Therefore, it is usually used rolling bearings or hydrostatic sliding bearing.

Secondly, because the hydraulic cylinder motor works under the input pressure oil conditions, it does not have to have the self-priming ability, but it needs a certain initial tightness to provide the necessary starting torque. Because of these differences, the hydraulic cylinder motor and the hydraulic pump are similar in structure, but they cannot work reversible.

What Advantages do We have as a Hydraulic Motor Manufacturer?

Long history of hydraulic motors for sale

Founded in 2000, JC forging is a professional hydraulic motor supplier of precision forging parts.

Custom hydraulic cylinder motors

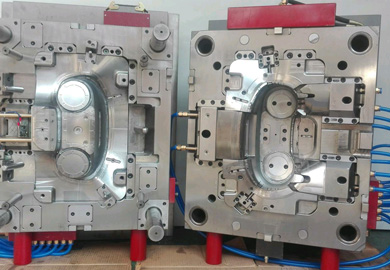

The company's main product is die mold forging parts, including but not limited to forged hydraulic cylinder bottoms, forged hydraulic cylinder end cap, forged hydraulic cylinder earring, and forged clevis, forged trunnions and other custom forged in metal parts.

Diverse forged iron products

JC forging is one of the most complete hydraulic motor suppliers with a wide range of hydraulic cylinder forgings in China. The company has 4 friction press production lines(630 to1600 tons) and more than 40 precision machining equipment, heat treatment equipment.

Strong capability beyond other hydraulic motor manufacturers

JC forging can produce 0.5-50kg precision die forgings, with an annual output of 5,000 tons of precision custom forged parts. Since its establishment, JC forging has cooperated with most of the well-known oil hydraulic motor manufacturers in China. Compared with other hydraulic motor manufacturers, its products have been exported to more than 20 countries and regions around the world.

JC forging is a professional forged components manufacturer, we provide hydraulic cylinder components, small hydraulic wheel motor, custom forgingpart and etc.

Send product request

Other supplier products

| Hydraulic Steering Control Units | The hydraulic steering gear is a hydraulic power steering type between the steering wheel and the steering mechanism, which does not need to be con... | |

| Forged Trunnion | Product: forged trunnion ak Application: hydraulic cylinder, truck Place of origin: Hebei, China (Mainland) Material: C45, 20, ASTM A216 7... | |

| BM3 Cycloid Hydraulic Motor | What is BM3 Cycloid Hydraulic Motor? The BM3 hydraulic motor is a shaft-loaded cycloidal hydraulic motor with higher load capacity and can be used... | |

| Hydraulic Cylinder | Hydraulic cylinder is an actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or oscillating mo... | |

| TG-E Multi-stage Hydraulic Cylinders | What is TG-E Multi-stage Hydraulic Cylinder? TG hydraulic cylinder is a single-acting multi-section telescopic sleeve lift cylinder. It has the adv... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |