Hydraulic Cylinder End Cap

Product: hydraulic cylinder end cap

Application: hydraulic cylinder

Place of origin: Hebei, China (Mainland)

Material: C45, 20, ASTM A216 70-36 grade WCB

Process: die mold forged, forging + CNC machining,

Surface treatment: anti-rust oil or painting

Surface roughness: 12.5Ra

Weight: 0.5-50kg

Sample lead-time: 3-8 weeks

Heat treatment: normalizing, quenching, tempering and annealing

Hydraulic cylinder capis also known as “blind end”. Because hydraulic cylinder end cap is inside the cylinder barrel and not exposed to daylight, hence the name. This part encloses the pressure chamber from one end of the hydraulic cylinder. The cylinder head has the option for an integrated rod sealing arrangement or an option for a seal gland.

Hydraulic Cylinder End Cap

Product Description

Hydraulic Cylinder End Cap Description

Customized drawings are accepted

Standards: ASTM, AISI, ANSI, AWS, ASME, AB, SAE, API, BS, CAS, JIS and DIN

Packing: seaworthy packing or as per clients' requirements

Competitive advantages of hydraulic cylinder end cap:

The forged hydraulic cylinder end cap used on different type of cylinders, strong and durable.

The precision forging process of hydraulic cylinder end cap can guarantee the material without defect inside the parts.

We can provide machined hydraulic cylinder end caps according to customer’s drawings.

Forging is a process method that uses forging machinery to exert pressure on metal blanks, causing them to create plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. By forging can eliminate the metal in the smelting process of the casting state loose and other defects, optimize the microstructure, and because of the preservation of complete metal streamlined, forging mechanical properties are generally better than the same material castings

For more information about custom metal forgingsand custom forged parts, please feel free to contact us!

Send product request

Other supplier products

| Hydraulic Cylinder End Cap | Hydraulic Cylinder End Cap Product: hydraulic cylinder end cap Application: hydraulic cylinder Place of origin: Hebei, China (Mainland) M... | |

| Forged Hydraulic Cylinder Head | As a reliable custom metal forged components manufacturer, JC Forging provides custom forged parts of various shapes, such as forged hydraulic cyli... | |

| Crane Truck Cylinder | What is Crane Truck Cylinder? The truck-mounted series cylinders include a front horizontal cylinder, a rear crane boom hydraulic cylindersa front... | |

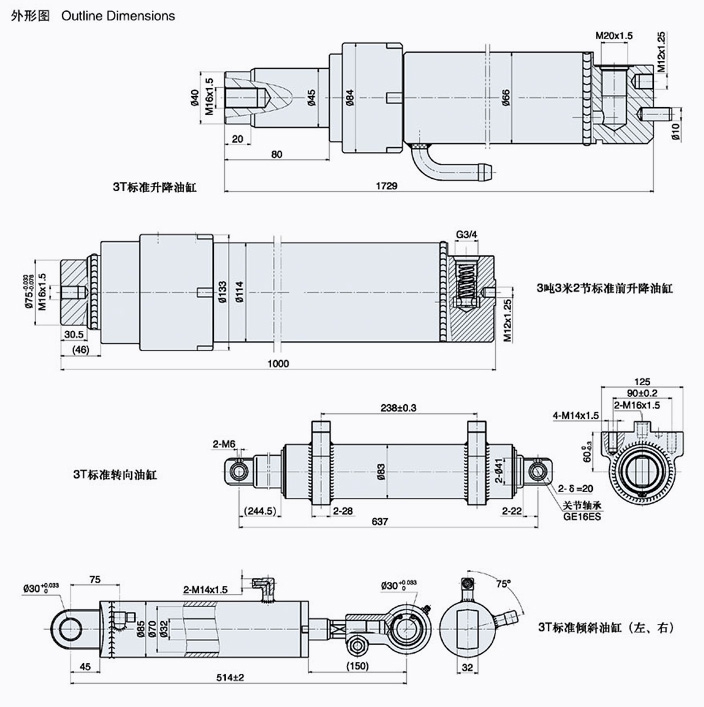

| Forklift Series Cylinders | Forklift Series Cylinders What is Forklift Series Cylinder? The forklift hydraulic lift cylinder include tilt cylinders, lift cylinders, steering c... | |

| Hydraulic Cylinder | Hydraulic cylinder is an actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or oscillating mo... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |