Rene Alloys Vacuum Investment Casting Service

Introduction to Rene Alloys Vacuum Investment Casting Service

Rene alloys are a series of high-performance nickel-based superalloys that are engineered to provide exceptional strength, oxidation resistance, and creep resistance at high temperatures. These alloys are crucial in demanding industries such as aerospace, power generation, and turbine manufacturing, where components must withstand extreme thermal and mechanical stress. At NewayAero, our Rene Alloys Vacuum Investment Casting Service offers the precision and reliability required to produce complex, high-performance components from these advanced materials.

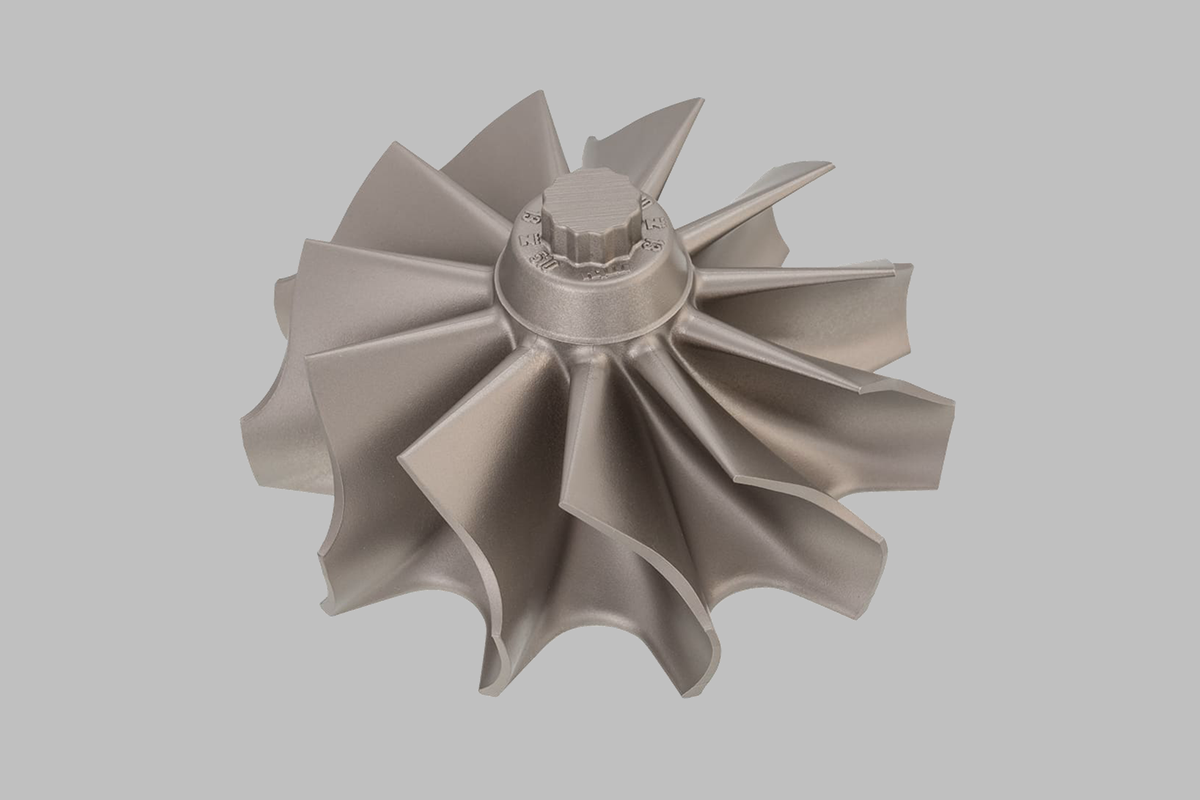

The vacuum investment casting process is ideal for manufacturing intricate parts with tight tolerances and excellent surface finish, which are essential when working with Rene alloys. This process begins by creating a wax pattern of the desired component. The pattern is then coated with a ceramic shell through repeated dipping and drying, followed by heating to remove the wax, leaving behind a hollow mold. The mold is placed in a vacuum chamber to create a controlled environment, ensuring minimal contamination and high-quality casting. Molten Rene alloy is then poured into the mold, filling the cavity to form the part. The vacuum environment minimizes the presence of gases that could weaken the material, ensuring the purity and strength of the final casting.

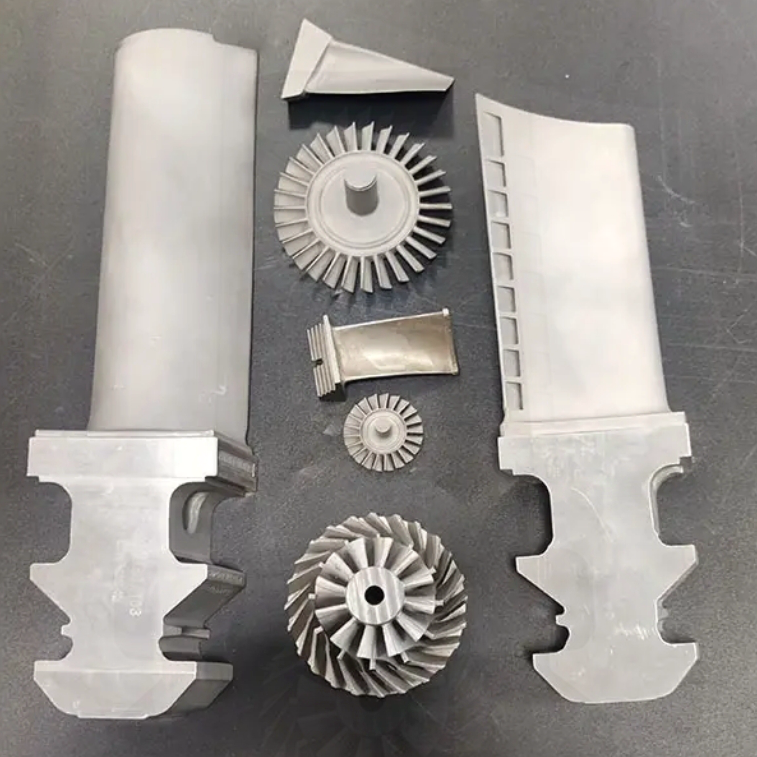

After the mold is cooled and solidified, the ceramic shell is removed, and the part undergoes various post-casting processes such as heat treatment, surface finishing, and machining to meet the final specifications. These post-casting processes improve the mechanical properties of the part, enhancing strength, fatigue resistance, and performance under high temperatures. The vacuum investment casting method allows for the production of parts with complex geometries, such as turbine blades, combustion chambers, and other critical components that demand high precision and durability.

By utilizing advanced casting techniques, NewayAero ensures that each Rene alloy component meets the highest standards of quality, performance, and reliability, ideal for extreme applications across aerospace and power generation.

Rene Alloys for Vacuum Investment Casting

Rene alloys are selected based on their unique properties that suit specific applications. Some of the most commonly used grades for vacuum investment casting include:

Rene Alloys Grades for Vacuum Investment Casting

-

Rene 104

Rene 108

Rene 142

Rene 41

Rene 65

Rene 77

Rene 80

Rene 88

Rene 95

Rene N5

Rene N6

For example, Rene 104 is widely used for its exceptional creep and oxidation resistance, making it ideal for turbine blades and other components in gas turbines. Rene 108 offers superior high-temperature strength and is often used in the most extreme conditions, such as in aerospace engines and high-stress turbine components. Other grades like Rene 142 and Rene 95 are also known for their outstanding mechanical properties at elevated temperatures and are commonly used in critical aerospace and power generation applications.

At NewayAero, our Rene Alloys Vacuum Investment Casting Service ensures that every part produced meets the exacting standards required for high-temperature, high-performance applications, providing our clients with components that deliver reliability and durability in the most demanding environments.

Send product request

Other supplier products

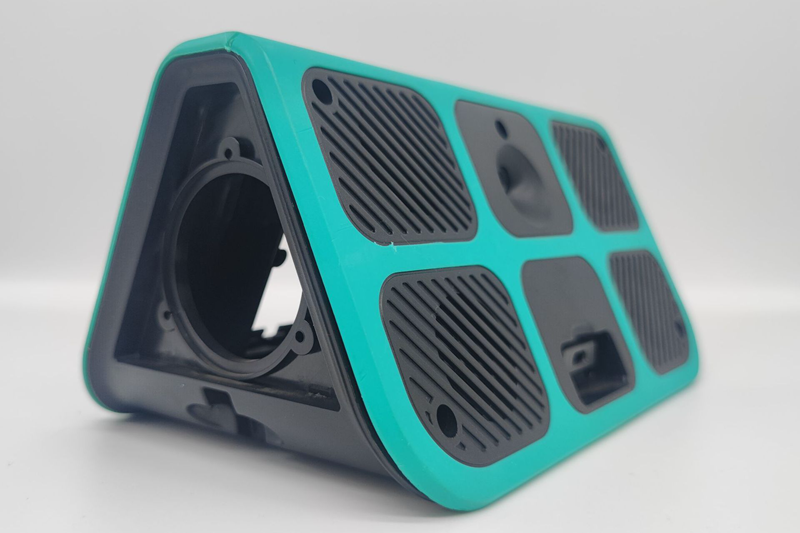

| Custom Overmolding Process | Access 30 years of experience as a custom overmolding manufacturer for your custom parts. Get exceptional customized overmolding parts with high ... | |

| Custom CNC Machining Service | With our custom CNC machining services, you can expect nothing but the best. Our team uses the latest technology and techniques to deliver result... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel alloys, known for their exceptional strength and re... | |

| Casting Superalloys (High temperature alloys) Vacuum Investment Casting | At , we specialize in high-performance casting services for superalloys, focusing on for the most demanding applications. Our Vacuum Investment Ca... | |

| Custom Precision Cast Parts Manufacturing Service | Our custom precision cast parts manufacturing services are mainly die casting, lost wax casting, sand casting, and gravity casting. According to ... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |