Stellite Alloy Superalloy Precision Forging Service

Introduction to Stellite Alloy Superalloy Precision Forging Service

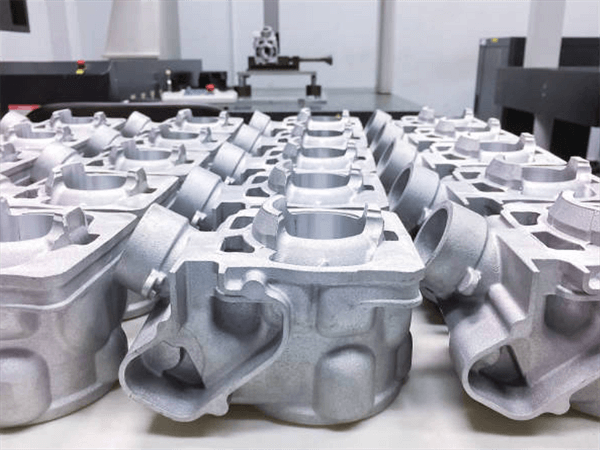

Stellite alloys are a group of cobalt-based superalloys that are known for their excellent wear resistance, hardness, and ability to withstand high temperatures. These properties make Stellite alloys an ideal material choice for demanding applications in industries such as aerospace, automotive, chemical processing, and power generation. At NewayAero, ourStellite Alloy Superalloy Precision Forging Servicecombines advanced forging technology with high-quality Stellite materials to create precision-engineered components that deliver exceptional performance in the harshest environments.

Theprecision forgingprocess for Stellite alloys involves shaping and forming the alloy through a series of controlled steps, where the material is heated to a temperature just below its melting point and then mechanically deformed under high pressure. This process allows for the production of parts with tight tolerances, improved material properties, and enhanced strength, making it ideal for high-performance applications where precise geometries are crucial. Precision forging also reduces material wastage compared to traditional casting processes, improving both material yield and cost-efficiency.

The forging process begins with the careful selection and preparation of the Stellite alloy material. The material is then heated to the appropriate forging temperature, typically between 1,100°C and 1,300°C (2,012°F to 2,372°F), depending on the specific grade and application. The heated Stellite alloy is then placed into a die, where it is subjected to controlled mechanical forces to achieve the desired shape and dimensions. Theprecision forgingprocess also refines the microstructure of the material, resulting in improved grain structure, mechanical properties, and overall durability.

By incorporating the latest forging technologies and quality control methods, NewayAero ensures that eachStellite alloypart produced meets the stringent requirements of industries like aerospace and power generation. The result is high-performance components capable of withstanding extreme wear, heat, and pressure, ensuring reliability and efficiency across a wide range of applications.

Stellite Alloys for Superalloy Precision Forging

Stellite alloysare available in various grades, each tailored to meet the specific requirements of different industries. These alloys are renowned for their excellent wear resistance, corrosion resistance, and ability to withstand high temperatures, making them ideal for applications in harsh environments. The most commonly used grades for superalloy precision forging include:

Stellite Grades for Precision Forging

-

Stellite 1

Stellite 12

Stellite 20

Stellite 21

Stellite 25

Stellite 3

Stellite 31

Stellite 4

Stellite 6

Stellite 6B

Stellite 6K

Stellite F

Stellite SF12

Each of these grades offers distinct advantages depending on the application. For example,Stellite 6is known for its exceptional wear and corrosion resistance, making it ideal for valve seats and other components exposed to harsh environments.Stellite 6Bis an enhanced version of Stellite 6 with improved resistance to wear and thermal fatigue, whileStellite 12is designed for applications requiring excellent oxidation resistance at elevated temperatures.

AtNewayAero, we use state-of-the-art forging equipment and advanced process controls to ensure that each Stellite component is manufactured to the highest standards. Our commitment to precision and durability ensures superior performance for even the most demanding applications.

Send product request

Other supplier products

| Aluminum Casting Service: Aluminum Die Casting | We offer custom aluminum casting services from design to finished aluminum die castings. We aim to provide customers with excellent custom alumin... | |

| Monel Alloy Equiaxed Crystal Casting Service | Introduction to Monel Alloy Equiaxed Crystal Casting Service Monel alloys, a family of nickel-copper alloys, are widely recognized for their excep... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components Inconel alloypowder metallurgy(PM) tu... | |

| Custom CNC Machining Service | With our custom CNC machining services, you can expect nothing but the best. Our team uses the latest technology and techniques to deliver result... | |

| Custom Gravity Cast Service | Explore the differences between gravity casting and other casting methods to determine the best choice for your project. Material rang: ADC12,... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |