Polyester Woven Dryer Mesh

Polyester Woven Dryer Mesh

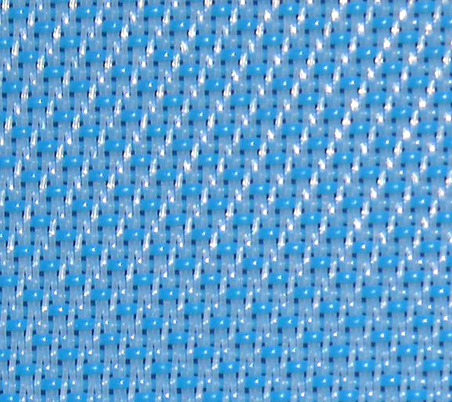

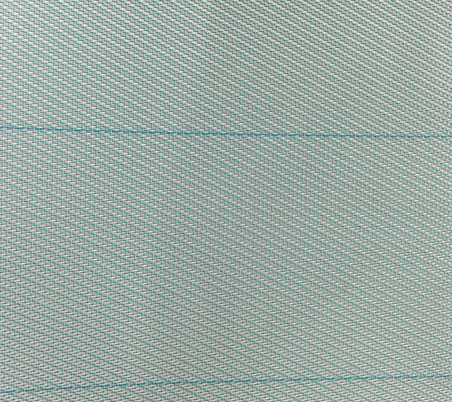

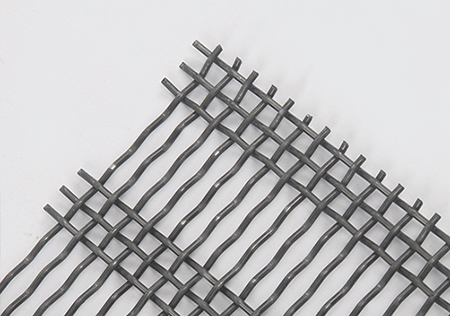

PolyesterDryerWovenMeshScreenFabriccan be divided into 3-shed, 4-shed according to the weaving. It can be divided insert, pin, pin ring and spiral ring join according to the interface type.

·Polyester Dryer Woven Mesh Screen Fabriccan be divided into 3-shed, 4-shed according to the weaving. It can be divided insert, pin, pin ring and spiral ring join according to the interface type.

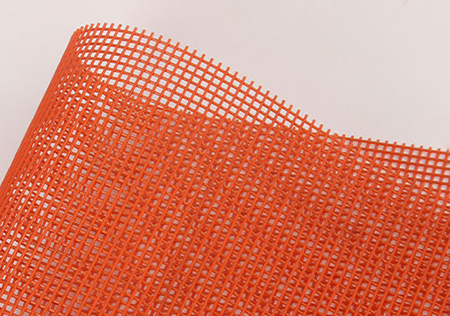

·22504/24504/4106 synthetic dryer wire mesh mainly used in the latter part of the muti-cylinder paper machine becuase its higher permeability, generally it is suitable for drying papers above 70g.

·4106-2/16904 synthetic dryer wire mesh generally used for multi-cylinder paper machine, the first three groups of paper drying, high-grade paper.

·4106-2/16904 synthetic dryer wire meshgenerally used in the fore group of paper drying, high-grade papers are all available.

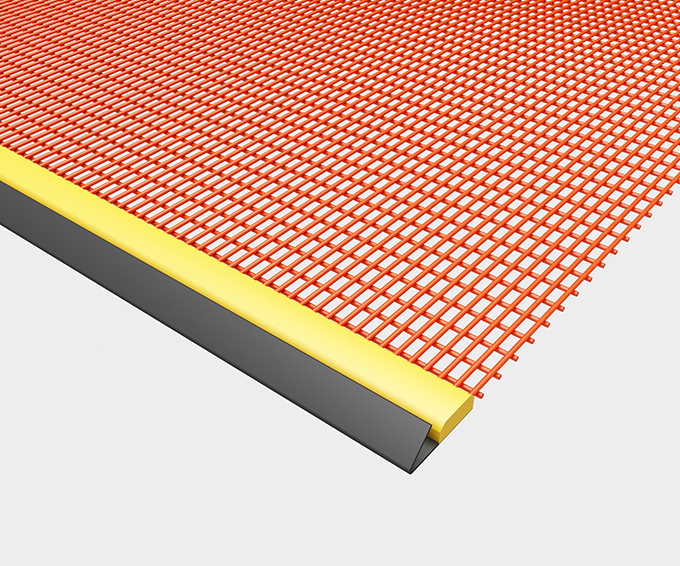

According to the category, polyester dryer fabricscan be divided into one and a half layer dryer fabric, double layer fabric, flat wire dryer fabric, flat double warp wire dryer fabric and special material dryer fabric.

3-shed, 4-shed one layer and a half are suitable for drying cultural paper, printing paper and packing paper etc.

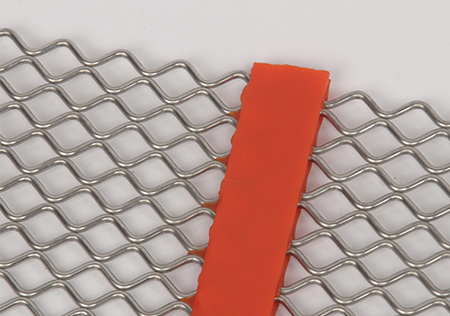

Flat wire and flat double warp wire dryer fabric is suitable for the fore several heating box of the drying zone, quality papers can use the both.

Special material dryer fabric have the characteristics of high temperature resistance, abrasion resistance and aging resistance etc.

|

Weaving series&Types |

Model of Fabrics |

Wire Diameter(mm) |

Density(wire/cm) |

Strength(N/cm) |

Air permeability (m3/m2/h) |

||

|

Warp |

Weft |

Warp |

Weft |

Area of the surface |

|||

|

3-shed series |

22503 |

24 |

Weft |

≥2000 |

8000±500 |

||

|

4-shed series |

20504 |

22 |

12 |

≥1900 |

13000±500 |

||

|

22504 |

24 |

12 |

≥2000 |

12000±500 |

|||

|

24504 |

26 |

12 |

≥2100 |

11000±500 |

|||

|

Round wire fabric |

4106 |

22 |

≥2000 |

6800±500 |

|||

|

Flat wire fabric |

4106-1 |

15 |

≥2000 |

5954±500 |

|||

|

4106-2 |

18 |

≥2000 |

4800±500 |

||||

|

SL4106 |

≥2100 |

6000±500 |

|||||

|

SJ1860 |

9 |

7 |

≥2200 |

2100±500 |

|||

Send product request

Other supplier products

| Polyester Press Felt | Polyester Press Felt High quality press felt and dryer felt for paper making machine The press felt plays an important role in removing the water... | |

| Double Layer Press Belts | Double Layer Press Belts Double Layer Press Felts include 1+1 composite structure and double layer of MD yarn structure. The 1+1 composite structu... | |

| Polyester sludge dewatering mesh | Sludge Dehydration Fabric (Press-Filter belt) for dewatering machine Polyester sludge dewatering mesh Sludge Dehydration Fabrics (Press-Filter Fabr... | |

| Single Layer Polyester Forming Fabric | Single Layer Polyester Forming Fabric Polyester Forming Fabric Introduction: According to the weaving type, Polyester forming fabricscan be divide... | |

| Polyester Forming Fabric Weaving for Paper Making | Polyester Forming Fabric Weaving for Paper Making polyester forming fabric, polyester paper making fabric Product description: Papermaking endless ... |

Same products

| China Manufacturer Swimming Pool Fence | Seller: Zhejiang Tiantai Advans Textile Co., Ltd. | Model POOL FENCE10 Material 1000*1000D PVC MESH +Aluminium Tube Height Normal 4' Color Black, ... | |

| Anpeng Woven Wire Mesh | Seller: Anpeng Wire Mesh Filter Equipment Co., LTD | As one ofprofessional woven wire mesh manufacturers, Anpeng wire screens should be your first cho... | |

| Slotted PU Mesh Wholesale | Seller: Anpeng Wire Mesh Filter Equipment Co., LTD | Anpeng PU-Mesh are made of abrasion-resistant polyurethane materials with steel wire structure em... | |

| Anpeng Self Cleaning Screen Mesh | Seller: Anpeng Wire Mesh Filter Equipment Co., LTD | Anpeng self cleaning wire meshseries is designed for though to screen applications where blinding... | |

| Anpeng PU-Mesh | Seller: Anpeng Wire Mesh Filter Equipment Co., LTD | Anpeng PUMeshscreens are made of abrasion-resistant polyurethane materials with steel wire struct... |