1050 1060 1070 3003 CC/DC Aluminum circles are used to make cookware/lighting/traffic signs

Aluminum circles, as the name suggests, are aluminum materials with a circular shape. It is mainly made of aluminum alloy. They are usually made by stamping or cutting aluminum plates and have good conductivity, corrosion resistance and machinability. Common alloy series include 1 series, 3 series, 5 series, 6 series and 8 series, among which 1 series (such as 1060, 1070), 3 series (such as 3003), 5 series (such as 5052, 5083) and 6 series (such as 6061, 6063) are the most common.

CC/DC aluminum circle specifications:

Alloy: 1060, 1050, 1070, 1100, 3003, 5052, etc.

Temper: O/Ho, H12, H14, H18, H24, hard, soft, stretching

Process: cold rolling or hot rolling

Thickness: 0.2-160 mm

Diameter: 100-1250 mm (diameter tolerance: +/-2 mm)

Application areas of aluminum disc:

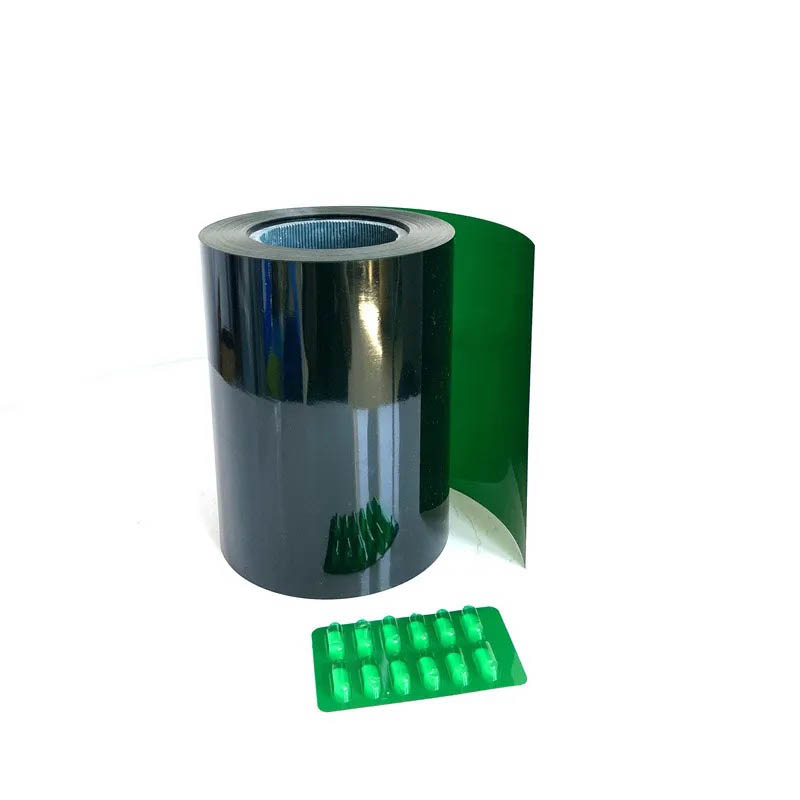

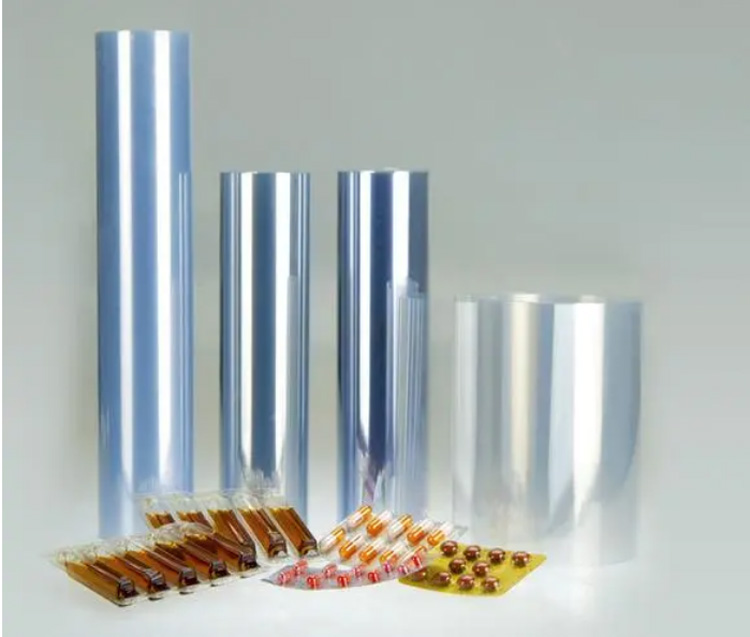

Aluminum circles have a wide range of applications, mainly including electronics, daily chemicals, medicine, culture and education, and auto parts. Aluminum disc also play an important role in electrical appliances, insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other fields. For example, in kitchenware, aluminum circles are used in the manufacturing process of products such as non-stick pans and pressure cookers; in hardware products, aluminum discs are also used in the production of products such as lampshades, water heater shells, and stretch tanks.

Aluminum Plates and Rounds Depending on the usage, aluminum rounds with different thickness, diameter and alloy composition can be selected to meet specific needs.

FAQ:

Q1: Where is your factory located?

A1: Our factory is in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

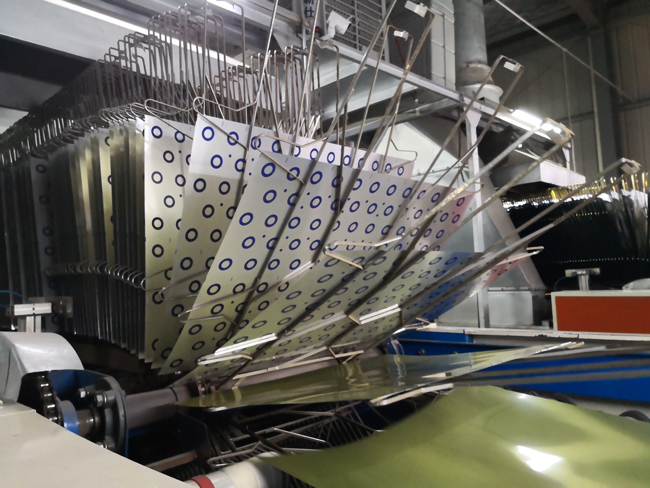

Equipped with various machines, such as aluminum plate machine, aluminum round machine, embossed aluminum coil machine, aluminum roof sheet machine, kraft paper/polysurlyn/pvc film coated aluminum coil machine, aluminum foil machine, etc.

Q2: What are the main products of your company?

A2: Our main products are aluminum plates/sheets, aluminum foil, aluminum coil, aluminum round/circle, aluminum roof sheet, aluminum coil with blue pvc film, embossed aluminum plates/sheets, color coated aluminum coil/sheets, aluminum tubes, aluminum wires, aluminum rods, PS/CTP sheets, etc.

Q3: How do you control quality?

A3: Factory test certification is provided with the goods, and third-party inspection can be provided.

Q4: How can I get your quotation?

A4: Please mention alloy and state, application, thickness, tensile strength, elongation, etc., we will quote as soon as possible.

Q5: How about the delivery time?

A5: Usually about 7-35 days, depending on different order requirements.

Q6. Can you provide samples?

A6: Yes, small samples are free, freight collect.

Customized samples take about 5-7 days.

Other supplier products

All supplier products

Same products

|

|

1050/1060/3003/5052/5083 Aluminum Discs for Cookware and Traffic Signs |

Seller: Henan Hongchang Aluminum Co., Ltd. |

Aluminum discs (also called aluminum circles) are produced from high-quality aluminum coils throu... |

|

|

Painted Aluminum for PP/ROPP Cap |

Seller: Zhengzhou Haomei Industrial Co., Ltd. |

It is applicable for cosmetics, yogurt caps, pharmaceutical bottle caps, milk tear-off caps, anti... |

|

|

Marine Grade Aluminum 5083 |

Seller: Zhengzhou Haomei Industrial Co., Ltd. |

With 5083 aluminum sheet replacing traditional steel ship, each ship can save about 8-100 tons of... |

|

|

5052 Aluminum Sheet Plate |

Seller: Zhengzhou Haomei Industrial Co., Ltd. |

5052 Aluminum Sheet/Plate belongs to Al-Mg alloy with magnesium as its main alloy elements. Of ot... |

|

|

High quality 3mm, 4mm, 5mm, 8mm 5083 H116/H321/H112 aluminum plates for ships, DNV/CCS certified sheets |

Seller: Henan Hongchang Aluminum Co., Ltd. |

Product information: 5083 aluminum alloy belongs to the Al-Mg series of rust-proof aluminum alloy... |