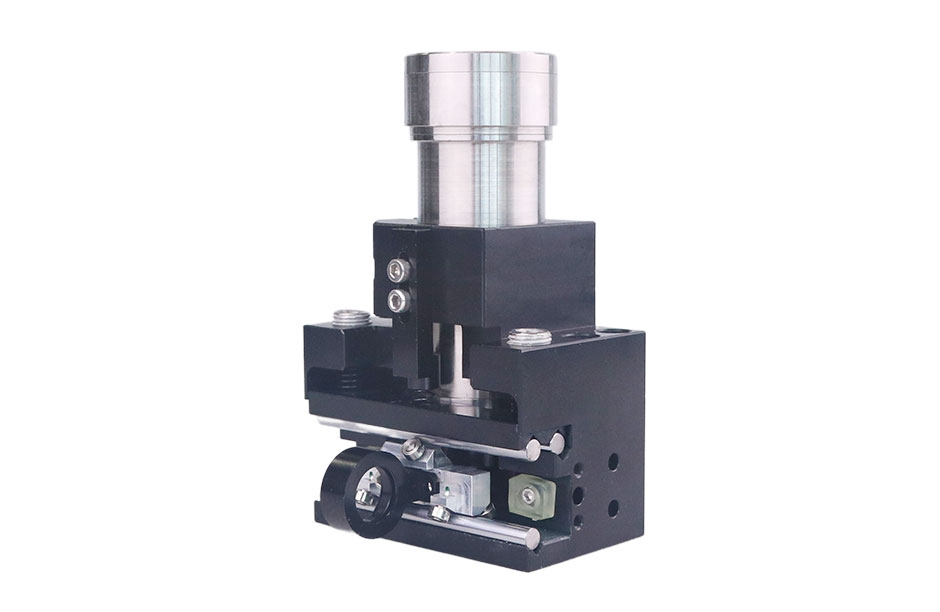

5-axis Laser Micromachining System

5-axis Laser MicromachiningSystem

The ordinary precession drillingsystem can only process the taper hole, and can not achieve the standard straight hole and inverted cone hole processing. Besides the standard straight hole and the taper hole processing, the 5-axis laser micro machining system can also process the inverted cone hole, which greatly expands the laser drilling applications. With different wavelengths and super fast lasers, the thermal effect of drilling is small and the surface treatment is smooth. Only by making the processing materials unlimited, has been applied to drilling and processing in all walks of life.

Key Features Of 5-axis Laser Micromachining System

In order to ensure accurate synchronization, it is necessary to process the position data of each axis under the same processor and control clock. This design uses high speed digital chip FPGA to achieve

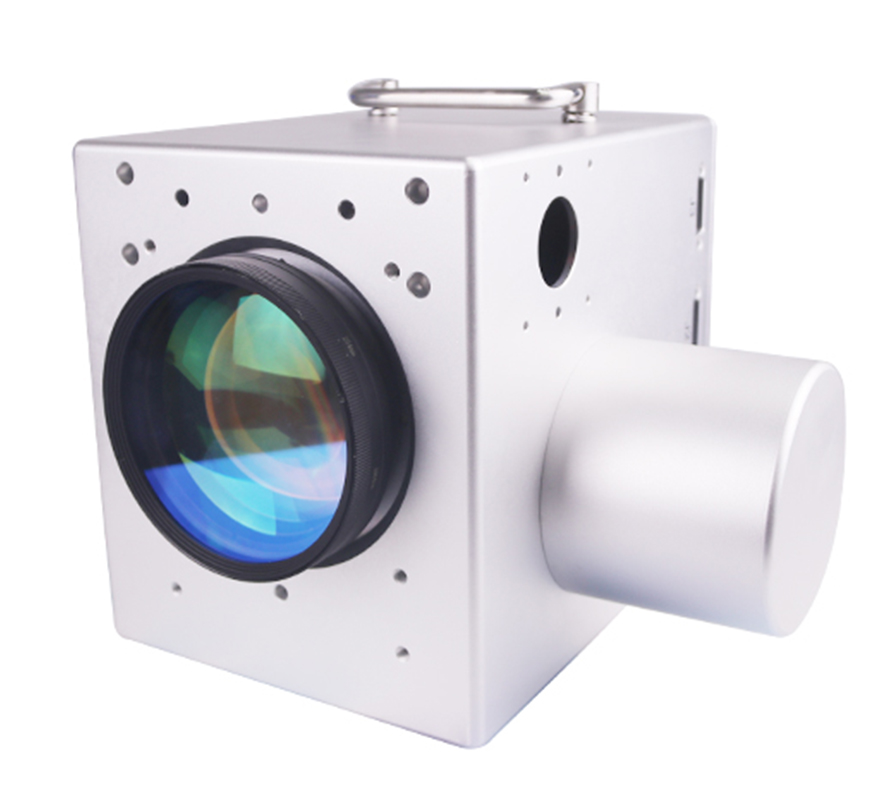

The positioning accuracy of the galvanometer will directly affect the machining accuracy of the equipment, and the factors affecting the positioning accuracy of the galvanometer mainly include the accuracy of the galvanometer feedback system, controller and the accuracy of correction.

The self-developed 24-bit high-precision encoder, combined with the high bandwidth driver based on PID and feedforward controller, improves the control accuracy of the system.

Adopt high-precision CNC machine tool to fix and clamp important structural parts at one time to ensure high-precision installation of galvanometer motion module.

Specifications Of 5-axis Laser Micromachining System

|

Working field size (Diameter, Depending On Nozzle Opening) |

mm |

φ0.025mm to φ1mm |

|

Maximum Focus Range In Z Direction |

mm |

±1mm |

|

Entrance Beam Diameter (1/e2) |

mm |

10mm |

|

Focus Diameter In Image Field (1/e²) for M² = 1 |

um |

25um |

|

Maximum Angle Of Incidence |

18° |

|

|

Precession Frequency |

HZ |

200-600HZ(rpm) |

|

Objective Focal Length |

mm |

50mm |

|

Repeatability |

um |

≤0.5um= |

|

Theoretical Resolution Of Incidence Angle |

urad |

2urad |

|

Dimension(L*W*H) |

mm |

601×280×274 |

|

Weight |

Kg |

Hansscannerprovides galvo head, galvanometer scanner, laser micromachining ppt, polygon scannerand etc. If you want to know more, please contact us.

Send product request

Other supplier products

| 5-axis Laser Micromachining System | 5-axis Laser MicromachiningSystem The ordinary precession drillingsystem can only process the taper hole, and can not achieve the standard strai... | |

| 3-axis Galvo Scan Head | The large-format 3D laser scanner headis free of the processing range limits of 2D field lenses, and can be flexibly selected 100x100mm-2000x2000mm... | |

| Laser Scanning System From Han's Scanner | Laser Scanning System From Han's Scanner Han's Scanner focuses on scanning galvanometersystem solutions. Our products include Ultragalvo photoelec... | |

| F-theta Lens | What is f theta lens Han's Scanner telecentric f theta lensseries products are the most commonly used parts in the laser field. After our continuo... | |

| Galvo Scanner | The single-axis galvo motor systemcontains a high-precision sensor and a motor part based on moving magnet technology. The motor rotor is optimized... |

Same products

| Ultra-galvo Scanner | Seller: Shenzhen Han\'s Scanner S&T Co., Ltd. | Ultra-galvo Scanner The galvanometer scanner laser using photoelectric sensor as feedback system... | |

| Scan Heads | Seller: Shenzhen Han\'s Scanner S&T Co., Ltd. | Scan Heads UltraScan products cover a comprehensive range of models, suitable for customers with... | |

| Polygon Scanner | Seller: Shenzhen Han\'s Scanner S&T Co., Ltd. | Polygon Scanner Different from laser galvanometercontrol technology, polygon laser scanner has r... | |

| Galvo Scanner | Seller: Shenzhen Han\'s Scanner S&T Co., Ltd. | Galvo Scanner The single-axis galvo motorsystem contains a high-precision sensor and a motor par... | |

| Laser Scanning System From Han's Scanner | Seller: Shenzhen Han\'s Scanner S&T Co., Ltd. | Laser Scanning System From Han's Scanner Han's Scanner focuses on scanning galvanometersystem so... |