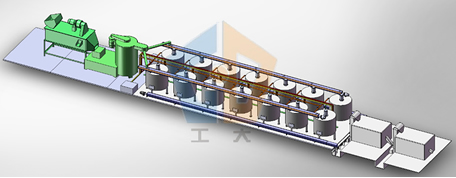

The new automatic malting equipment

The malting device , the newest invention of our company , is designed for small and medium-sized malting company .Totally different from readitional malting system , multi-storide construction for barley soaking and drying and the brick-mixed consreuction of germination box , as well as the output of the materials during the period from germination to drying are omitted .This malting system includes screening and clearing machines , malting unity machines , blowers , hot-air generators , polishing machines , deculming machines and packing , which not only improved , and produces high-quality malt . Malting unity machine integrates processes suchi an wheat soaking , germination , drying into one . Wheat soaking tanks , germination boxes and drying ovens will not be needed. While soaking wheat , the procedures such as pouring ,drainage , ventilation and water spraying are carried out automatically and can suit many kinds of soaking means .Once finished , there is no need to remove materials , wheat starts to germinate naturally . The wind temperature and humidity are controlled automatically and wheat will be turned over in time so as to ensure the quality of malt . After germination , drying treatment is carried out automatically , due to the drying procedures of high-efficient ovens with single layer so that energy consumption is reduced . Automation is realized throughout the whole process . This equipment is mainly applied to malt produce , including soaking , sprouting , drying processes , and it is also used to sprout and germinate for the other seed . The mainly function is use the ingress and egress of water and ventilation to finish the soaking process . made the barley basorb enough moisture and ensure the requirement of sprout .Then use the ventilation and spray system finish the barley sprout processing , wait for the malt grow up ,use the hot-wind system drying green malt , finish the whole malt produce process. The outstanding character of equipment is save the operate and produce space of soaking ,sproting ,drying processes , and integrate this three absolute processes in a all-in-one equpiment , save all construction project and leave out the feeding procedrue of the three working procedure , savings investment , saving labor force , energy conservation , reduce production costs and improve labor productivity .

Other supplier products

|

|

Automatic glass bottle-washing machine |

Automatic glass bottle-washing machine

1. Principal features

The machine contains the inner layer washing machine , the outside remove labeling m... |

|

|

beer filling machine |

1. Scope of application

It is mainly used in filling beer, soda drink, light sparkling wine, mineral water, etc.

2. Technical Features

GD Isobar... |

|

|

Column type filter machine |

Column type filter machine 1. Apply for Beer , yellow wine , syrup , beverage ,and some biology juice industry . 2. Filter principle This type of m... |

|

|

Vane-type diatomite filter machine |

Vane-type diatomite filter machine

1. There are two kinds of vane-type diatomite filter: vertical vane-type diatomite filter and level vane-type ... |

|

|

Beer filling capping 2-in-1 unit machine |

1. Principal features It is used for filling and sealing various kinds of glass bottle with crown type bottle mouth for beer filling production lin... |

All supplier products

Same products