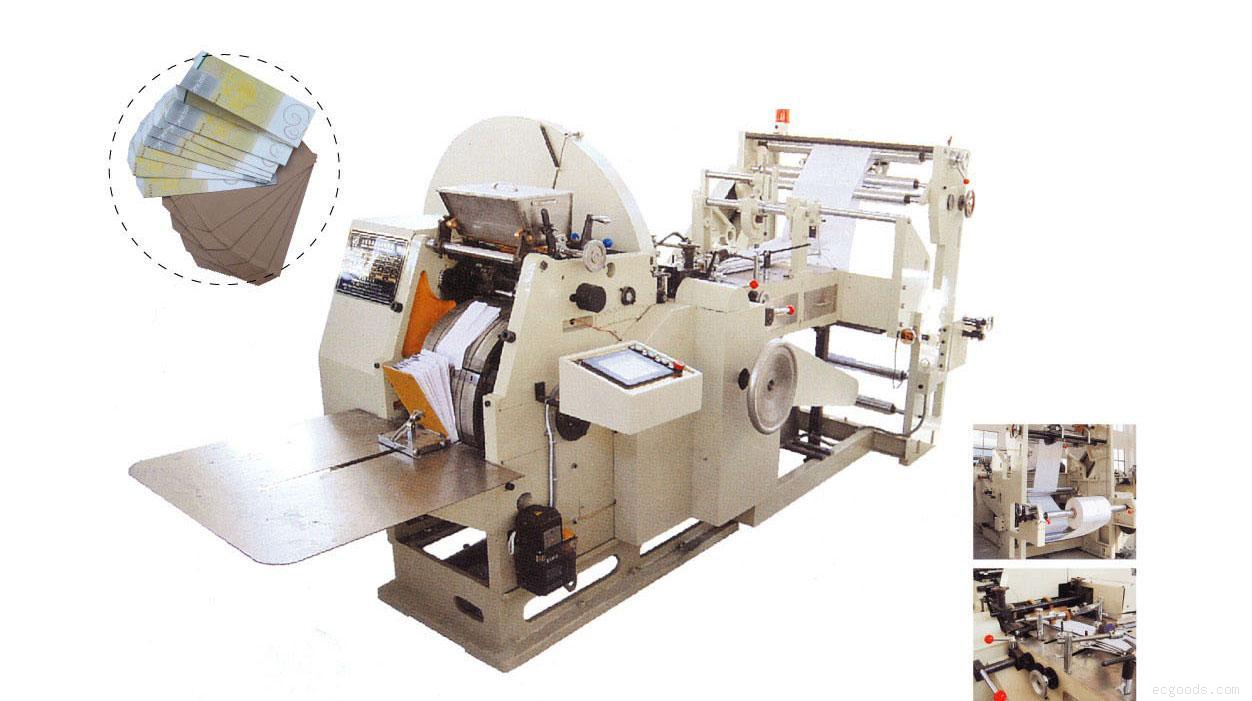

10KW 10 - 32 pcs / min energy-Saving paper yarn cement bag making machine

10KW 10 - 32 pcs / min energy-Saving paper yarn cement bag making machine

No.

Item

Index

Tank

Jacket (coil)

1

Design pressure mpa

Atmospheric pressure

Atmospheric pressure

2

Design temperature

℃

100

100

3

Working pressure

mpa

Atmospheric pressure

Atmospheric pressure

4

Operating Temperature

℃

<100

<250

5

Working medium

In liquid

HTF

6

main material

SUS304

SUS304

7

Corrosion allowance

mm

0

0

8

Weld factor

0.75

0.75

9

Heat transfer area

㎡

1.5

10

Power(KW)

0.75

11

Stirringspeed

rpm

47

12

Seal type

Mechanical seal

204B

13

Effective volume

m3

0.2

14

Full volume

m3

0.285

15

Heating power

KW

0.75

16

Container class

Outside the class

17

Dimensions

M

1.8 (L)×1.4 (W)×1.8 (H)

Introduction:

our factory developed this machine 8 years ago, on the basis of absorbing latest bag-making technology, we are continuing to improve its performance by integrating with latest technology from Europe.

Model WFD-650 sack-making machines are the latest products. They are successfully developed on the base of our original sack-making experience with incorporation of the advanced technical information, both domestic and foreign, and the result of our research work.. We have simplified many complex matching machines like“cirle loom”, “plastic injection machine” , “complex plastic film machine”, “printing machine”etc. Formerly used as macessary equipment in production. We have accomplished the work of arranging warp, and weft yarns in order by automatic, taking paper, gluing, temperature controlling

A. Characteristics:

Simplicity:

Its design simplifies bag making steps, unlike PP woven bag production line which includes plastic yarn extruding machine, circular loom, film blowing machine, laminating machine, printing machine, etc; the bag made by this machine only one step: feeding of two layers of paper, yam and glue to the machine, then bag tube as its end product, then sewing by industry sewing machine.

Excellence:

The machine has excellent properties with quick bag-making speed in about 25 bags/min, two color printing, smooth running, and one machine with two purposes, i.e. then sewing its bottom. Its entire quality index reached GB9774-1996 standard, and the waste bags can also be recollected. Therefore, it is an ideal green product to protect environment.

Compactness:

Since the structure of this machine has the feature of compactness in reasonable, it has no special requirement for the factory building.

Energy-Saving:

This machine only needs three workers, 9 KW consumption per 1000 bags making.

Quick Learning:

Installation and training period: within 15 working days.

Low Noise & low Cost, no pollution both bag making and bag itself

B. Usage & the Specialty of Cement Bag Produced by This Machine

The nylon-water soluble yam compound cement packing bag produced by this machine, is integrated by paper, yam, and water proof film, high temperature resistance, anti-aging, high strength, good permeability, and low cost, Meanwhile, it can be recollected totally without polluting environment to meet international EP standard.

The new cement-packing bags produced by this machine, after being sampling tested and inspected by the relative state quality supervision and inspection institute, accorded with the relative state GB9774-1996 standard in all of its quality index, and now is being turned out in batch.

The bags for packing all kinds of powder and granule materials such as cereal, starch, sugar, feed, chemical fertilizer, mineral products etc, can be produced by this machine.

C. Major Technical Data

1. Raw Material: normal paper or recycled paper-bag paper in 80g/m, and 1250mm of width, 18-20 count of yam or water soluble yam (or nylon yam), and 17-99PVA glue.

2. Specification: bag width 420mm, length 720-760mm, laid-in edge 8mm.

3. Fixed Operator: 3 persons

4. Speed of Bag-making: 10-32 pcs/min

5. Total Power: 10KW

6. Dimension: 1600x2500x2000(mm)

7. Weight: 5000KG

8.Bag length: unlimited

9. Bag width: 350-650mm

10: Side folding: Max 150mm

D. Technological Process

Warp in 416 spindles---gluing on threading---inter papers feeding and loop forming---warp-distributing---weft-netting---exterior papers feeding and binary color-printing---compounding both interior and exterior papers and the yam to loop-forming---compression roll-drawing and compounding---holes making---edge-folding---bags-cutting and counting---finished products.

E. After-sales Service:

1. Machine-transporting on commission basis.

2. Installing and adjusting the machine for free domestically.

3. Free training

We could customize our machinery to meet your especial requirements.

Send product request

Other supplier products

| 6KW high speed 60 - 300pcs / min food paper bag making machine for paper with 30-100 gsm | 6KW high speed 60 - 300pcs / min food paper bag making machine for paper with 30-100 gsm Introduction: In order to meet the requirements from our... | |

| 12kw 50HZ 3 Phase 4 Wire Multilayer Kraft Paper Sack Machine / Cement Bag Making Machine | 12kw 50HZ 3 Phase 4 Wire Multilayer Kraft Paper Sack Machine / Cement Bag Making Machine Place of Origin: China Brand Name: Model Num... | |

| 15.2kw 1160mm printing width combine with four-colors flexographic printing machine | 15.2kw 1160mm printing width combine with four-colors flexographic printing machine technical parameters Model:XRCDYJ-1204 Printing width:1160m... | |

| 20KW 630 - 1450MM High Speed Roll Fed Paper Bags Making Machines HD - 550 for Business | 20KW 630 - 1450MM High Speed Roll Fed Paper Bags Making Machines HD - 550 for Business HD-550 High-speed Roll fed Paper Bag machine is the new gen... | |

| 3.7 KW 5000pcs / h seasickness paper bags making machine quotation with display LCD | 3.7 KW 5000pcs / h seasickness paper bags making machine quotation with display LCD Introductions: This bag making machine is specially designe... |

Same products

| Embrace Intelligent Automation for Unmatched Box Production Efficiency | Seller: cenwan | 隆重推出我们的全自动智能高速折叠糊盒机,这是现代包装机械设计的巅峰之作。该设备融合了先进的机器人技术、智能传感技术和精密工程,可为各种瓦楞纸箱的生产提供真正的自动化体验。它旨在最大限度地提高产量... | |

| engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Engraving machine from China, low price and high quality, the machine is very good | |

| Precision engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Packaging machinery export trade service, delivering goods to Russia, Europe, professional custom... | |

| Efficient Film Cutting and UV Curing for Your Mobile Devices | Seller: Shenzhen Wikshu Technology Co. | Mechanic Auto X450 Intelligent Film Cutting and Laminating All in One Machine for Cutting Laminat... | |

| China Supplier Automatic Glass Bottle Juice Liquid Filling Machine for Beverage Plants | Seller: Professional Hebei Shenghui Pump Company | Thebeverage liquid filling machine is a ideal choice for precisely and quickly filling fluids wit... |