28KW 220V FD600 Paper Plastic Fabric Tube Cement Bag Making Machine For Chemical

28KW 220V FD600 Paper Plastic Fabric Tube Cement Bag Making Machine For Chemical

Place of Origin:

China

Brand Name:

Model Number:

FD-600

Certification:

ISO900

Minimum Order Quantity:

1 set

Price:

Get latest price

Packaging Details:

WOODENBOXESINCONTAINER

Delivery Time:

Payment Terms:

T/T L/C

Supply Ability:

Unlimited

1.Descrition:

This machine can make the rolled paper-plastic compounded sheet into the tubular paper pipes, with functions of pressing, forming, gluing, cut-off, counting, etc.

It is suitable for cement, chemical, grain packing.

List of materials

No.

Parts name

Parts type

quantity

1

Axial flow fan

100FZY2-S 220V

2

2

DELTA man- machine

5.7#

1

3

DELTA PLC

14 point

1

4

Main frequency converter (DELTA)

5.5KW

1

5

Encoder(made in Japan)

HBA-6G5-30F600B

1

6

Button(YUANDA)

2

7

Two position Rotary knob(YUANDA)

3

8

Power indicator light(YUANDA)

1

9

alarm equipment

1

10

Air switch 1P

DZ47-D16-2

1

11

Air switch 3P

DZ47-D30-3

1

12

Power Switch

MYT50-242424

1

13

Intermediate relay(ZHENGTAI)

HH52P/DC24V

2

14

Alternating current contactor

CJX2-5011

1

15

Emergency stop button(YUANDA)

1

16

Photoelectric switch(KONTEC)

WS-C2G-S

1

17

Proximity switch

JI2-D4NK

2 piece

18

Synchronizer gear and belt

96:24

1set

Applications:

It is suitable for cement, chemical, grain packing

Specifications:

1) Bag length: unlimited

2) Bag width: 400-600mm

3) Output: 30-80pcs/min

4) Fabric roll width: 820-1250mm

5) Total weight: 5000 kg

6) Total Power: 28Kw

User Manual:

1.Design parameter for control cabinet andlist of main materials

1.1 Design parameter

1.1.1Control cabinet power supply:380V/50HZ, 3 phase 5 wire

1.1.2 Power: 10 KW

1.1.3Control cabinet has a good grounding for static removing

1.1.4Materials: Carbon steel, outside power coating

1.1.5Color: computer color

1.1.6Cable into the line:inlet then out

1.1.7 Protection Level:IP3X

1.1.8Installation occasions: User MCC distribution room or at the scene

2.operation button introduction

2.1 Control Panel【Control Panel】

【power indication】: Indicator light, the lights on meanthe Control cabinet have the electricity

【power switch】: General power switch, screw the button, the system have the electricity

【system starting】: System running button, press the button, the machine starts working

【system stop】System stop button, press the button, the machine stop working

【frequency control】when the system is working, screw the button can change the speed of bag making

【wheel cutter switch 】wheel cutter on/off button

【color-marking switch】wheel cutter color-marking on/off button

【emergency stop】system emergency stop button, press the button, the system will don’t have electricity

1.Operation steps

3.1 Power connection for the control cabinet, turn the button“power on”and then the system has electricity.

3.2 press the button“system starting”on the control cabinet and the then system will start

3.3 Setting the bag length

Servo drive Operational Interface

press【PAR/ALM】, it will show F000, and then press the key“up down”to F535

press【RD/WT】, it will show the primary bag length, (unit: cm ), you can press the key“up down”to adjust the bag length

press 【RD/WT】to confirm the size of the bag, press the 【PAR/ALM】two times, and then press 【STOP/RESET】, the screen will show 0.By now , setting the bag length has finished

3.4 Starting the “wheel cutter” switch on the control cabinet

3.5 To choose whether start the color tracking function or not

3.6 Turn the frequency speed control button, the machine will be running, accelerate to the required speed slowly.

3.7 Press the button“emergency stop” in the case of an emergency

in order to cut off system power quickly.

3.8 Please press the button【system stop】when you want to stop the system.

4. Attentions

4.1Please disconnect all of the circuit breaker when the system doesn’t use for a long time.

4.2 Keep machine intact till our engineer finish installation

4.3 If not knowing the meaning of the parameters, please do not adjust all the parameters of frequency converter and wheel cutter drivers in the control cabinet, in case of any problems , please call us for advice

4.4Please periodically check the wiring screw in the control cabinet whether is loose, the connection wire connects bag making machine and control cabinet whether is broken.

4.5Control cabinet are 380V power of strong electricity, when the system is running , please close the cabinet doors to avoid danger.

Remark: Our company maintain the final right of interpretation.

5. Supporting machine

Model:SQFD-Ⅱ

Thermal rating:1.5kw

Press capacity:1500-2500pcs/h

Earnest power:1.5kw

Insalls The size:3000X1400X1100mm

Gross weight (approximately) :800kg

The machine adopts frequency control, smart temperature control, high-speed sewing configuration, mainly for chemical bags, finished tube of the cement bag, suture the bottom and then heat sealing the package edge; it is idea equipment for back over.

Sample Bags:

Send product request

Other supplier products

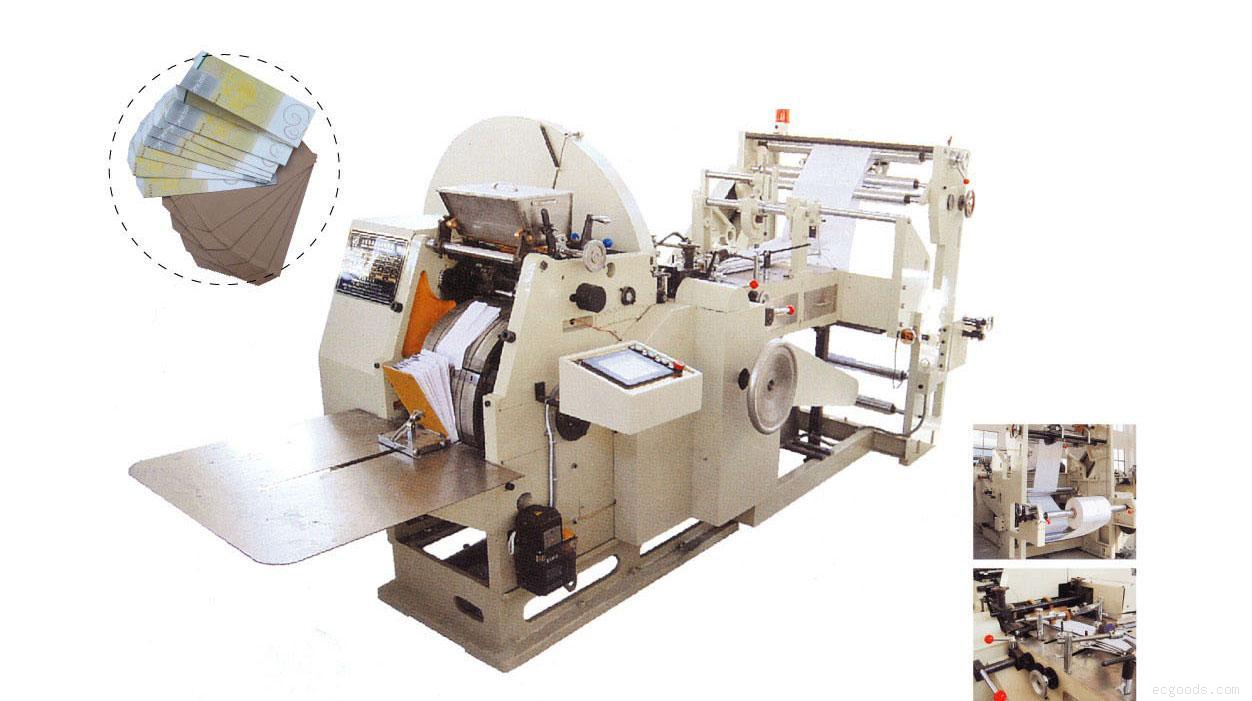

| 6KW high speed 60 - 300pcs / min food paper bag making machine for paper with 30-100 gsm | 6KW high speed 60 - 300pcs / min food paper bag making machine for paper with 30-100 gsm Introduction: In order to meet the requirements from our... | |

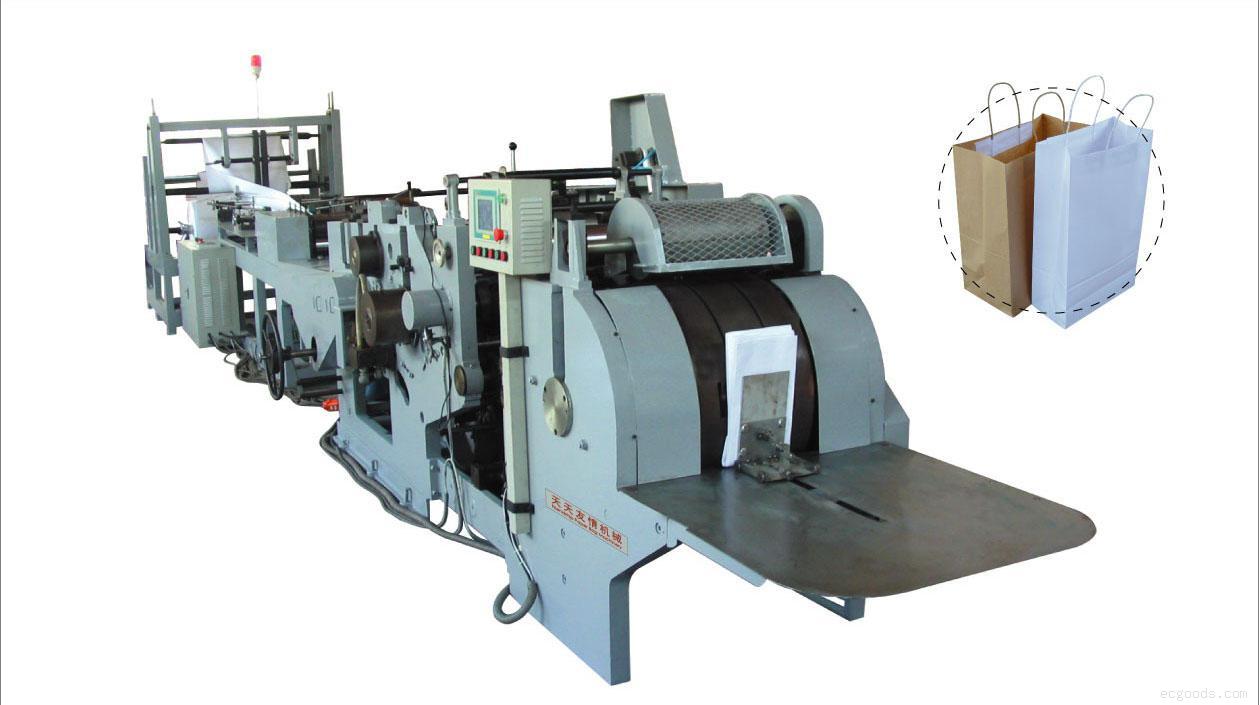

| 10KW, 18.5KW High Speed Roll Feeding Square Bottom Shopping Paper Bag Making Machine | 10KW, 18.5KW High Speed Roll Feeding Square Bottom Shopping Paper Bag Making Machine Third: HD-340 Sheet Feeding Paper Handbag Making Machine ... | |

| 12kw 50HZ 3 Phase 4 Wire Multilayer Kraft Paper Sack Machine / Cement Bag Making Machine | 12kw 50HZ 3 Phase 4 Wire Multilayer Kraft Paper Sack Machine / Cement Bag Making Machine Place of Origin: China Brand Name: Model Num... | |

| 15.2kw 1160mm printing width combine with four-colors flexographic printing machine | 15.2kw 1160mm printing width combine with four-colors flexographic printing machine technical parameters Model:XRCDYJ-1204 Printing width:1160m... | |

| 0.55KW Semi-automatic cement bag making machine for paper handle tube bag, chemic bag | 0.55KW Semi-automatic cement bag making machine for paper handle tube bag, chemic bag First: Semi-automatic cement bag production line It’s... |

Same products

| Embrace Intelligent Automation for Unmatched Box Production Efficiency | Seller: cenwan | 隆重推出我们的全自动智能高速折叠糊盒机,这是现代包装机械设计的巅峰之作。该设备融合了先进的机器人技术、智能传感技术和精密工程,可为各种瓦楞纸箱的生产提供真正的自动化体验。它旨在最大限度地提高产量... | |

| engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Engraving machine from China, low price and high quality, the machine is very good | |

| Precision engraving machine | Seller: Hangzhou siseyin Technology Co., Ltd | Packaging machinery export trade service, delivering goods to Russia, Europe, professional custom... | |

| Efficient Film Cutting and UV Curing for Your Mobile Devices | Seller: Shenzhen Wikshu Technology Co. | Mechanic Auto X450 Intelligent Film Cutting and Laminating All in One Machine for Cutting Laminat... | |

| China Supplier Automatic Glass Bottle Juice Liquid Filling Machine for Beverage Plants | Seller: Professional Hebei Shenghui Pump Company | Thebeverage liquid filling machine is a ideal choice for precisely and quickly filling fluids wit... |