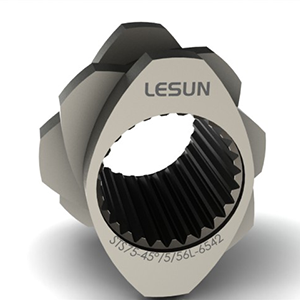

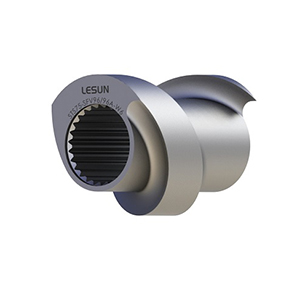

Backward Pumping Kneading Block

The backward pumping kneading block plays a role of adjusting the fullness of the material and extending the residence time of the material in the barrel during the material mixing. Its blocking force is weaker than the reverse feed screw sleeve, but slightly stronger than the 90 ° kneading block. Which area should choose the backward pumping kneading block? How to use it with the reverse screw sleeve in the full length? How many reverse elements should be selected for the full length of the screw? All of these questions are testing the experience and skill of the modification engineer, which has a considerable impact on the quality of the modified special material or masterbatch. For example, in the case of nylon (PA66) flame retardant enhanced modification, the first kneading zone must be stringed by four kneading blocks (such as 30 ° + 45 ° + 45 ° ++ 45 ° L), and must be finished by 45 ° L blocks Stuffing, the whole machine can stably plasticize and stably extrude the PA66, a strong crystalline plastic.

Technical Details of Backward Pumping Kneading Block

Brand:LESUN

Model:φ20 mm ~φ300 mm

Material:38CrMoALA / W6Mo5Cr4V2 / HIP

Properties: Wear-resisting, Corrode-resisting

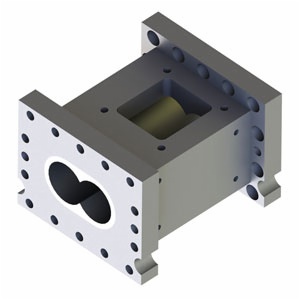

Application: Extruder

Backward Pumping Kneading Block Function

Processing Characteristics of Backward Pumping Kneading Block:

Nanjing Lesun Screw Co.,Ltd is a professional screw and barrel manufacturer. We provide extruder barrel, hexagonal shaft, Extruder Spare Parts, kneading blockand so on. Want to know about extruder screw price? Please contact us.

Send product request

Other supplier products

| Extruder Open Screw Barrel | The extruder open screw barrels are used in the feeding section, the natural exhausting section and the vacuum exhausting sections. Depending on th... | |

| Conveying Screw Element Manufacturer | The main function of the conveying twin screw elementsis to help the material forward in the cylinder, and it will determine the conveying speed ac... | |

| Kneading Screw Elements | The main function of the kneading blockscrew element is mixing, which is used for the distribution and dispersion of the materials. The strength an... | |

| Involute Spline Shaft | The plastic spline shaftis the form of mandrel splines used by all the twin screw extruders over the world. The standards of the spline are Chines... | |

| TWIN SCREW EXTRUDER PARTS MANUFACTURER | WITH REGARD TO PRODUCTION SPECIFICATIONS, LESUN NOT ONLY OFFERS STANDARD TWIN SCREW EXTRUDER PARTS MADE BY GENERAL SCREW EXTRUDER MANUFACTURER, BUT... |

Same products

| Pail Crimper | Seller: Chongyi Industries (Hangzhou) Co., Ltd. | pneumatic pail crimperis the sealing tool used to seal lids of metal open head containers, includ... | |

| METAL DRUM CAP SEAL | Seller: Chongyi Industries (Hangzhou) Co., Ltd. | Metal tab seal for drums, as know as tab seal, is generally made from tinplate material, sometime... | |

| Lacquered Drum Plug | Seller: Chongyi Industries (Hangzhou) Co., Ltd. | Lacquered steel drum plugsis G2 and G3/4 drum bung plugs with lacquered resins for better resista... | |

| Drum Tools | Seller: Chongyi Industries (Hangzhou) Co., Ltd. | Chongyi offers a comprehensive range of drum crimping toolfor usage of drum containers. Preciousl... | |

| Steel Drum Plastic Bung | Seller: Chongyi Industries (Hangzhou) Co., Ltd. | Steel drum barrel bungs plasticis G2 and G3/4'' plug type with ISO-228 thread, can well suit into... |