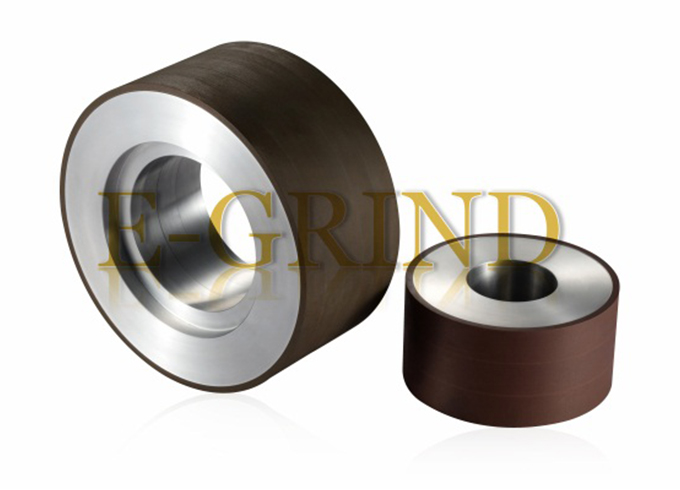

Diamond Grinding Wheel Dresser

E-Grind developed abrasive wheel dresser widely used in many metalwork industries like auto parts, engine and engine parts, mold, cutting tools, and other precision parts.

Our products greatly help our grinding wheel to provide perfect performance in cylindrical grinding, centerless grinding, surface grinding, and tool grinding processes.

Performance of diamond grinding wheel dressing tool

Stable quality control

Perfect tool life

Great save dressing cost

Help customers achieve the best performance from grinding wheel

Applications of Diamond Grinding Wheel Dresser

For truing, cleaning, and dressing diamond, CBN, and conventional abrasive wheels

Applicable to different machines such as cylindrical grinders, centerless grinders, surface grinders, and all CNC grinders

Tips on How to Dress A Diamond Grinding Wheel

Dressing a diamond grinding wheel requires precision and care to optimize its performance. Here are some tips to help you effectively dress a diamond grinding wheel:

Choose the Right Dressing Tool: Select a diamond grinding wheel dresser that is suitable for the specific type and grit size of your diamond grinding wheel. The dresser should match the wheel's specifications for optimal results.

Inspect the Wheel Before Dressing: Before starting the dressing process, thoroughly examine the diamond grinding wheel for any visible damage, such as chips or cracks. Ensure there is no uneven wear on the wheel's surface.

Ensure Proper Mounting: Secure the diamond grinding wheel dresser firmly in the tool holder or dressing arm of the grinding machine. Proper alignment and secure mounting are crucial for achieving accurate and even dressing.

Adjust the Tool Height: Set the height of the diamond dresser tool to the center of the grinding wheel. This ensures a consistent and even dressing across the entire wheel surface.

Maintain a Steady Feed Rate: Move the diamond dressing tool for surface grinder, maintaining a steady and consistent feed rate. This practice is vital for achieving an even dressing and preventing irregularities.

Follow Manufacturer Guidelines: Always refer to the grinding wheel dresser manufacturer's guidelines and recommendations for both the diamond wheel and the diamond dresser tool. Different wheels and tools may have specific requirements, and adhering to these guidelines ensures optimal performance.

E grind, as an excellent cbn grinding wheel suppliers, offers a wide range of crankshaft grinding wheels for you to choose from.

Other supplier products

|

|

Dicing Blade & Grinding Wheels For Semi-Conductor |

Henan E-Grind Abrasives Co., Ltd can offer the semiconductor industry cutting-edge dicing blades & grinding wheels of the utmost quality. Diamo... |

|

|

Grinding Wheel Dressing Stick |

E-Grind supply Dressing sticks to help you achieve maximum performance from your grinding wheel. For saving customers costs and time, we put 1 pc c... |

|

|

Centerless Grinding Wheels |

E-Grind Centerless wheels are widely used for grinding TCT cutting tools, bearing parts, automobile parts, plungers, cylinders and engine valves. F... |

|

|

Electroplated Tools |

Henan E-Grind Abrasives Co., Ltd. produces electroplated tools by plating diamond or CBN grains with a single layer of nickel. These electroplated ... |

|

|

Diamond Grinding Wheel Dresser |

As a diamond wheel manufacturer, E-Grind developed diamond dressers widely used in many metalwork industries like auto parts, engine and engine par... |

All supplier products

Same products