Instructions of Epoxy Zinc-Rich Primer

It is two components epoxy zinc-rich primer heavy corrosion by zinc primer paint, epoxy resin and other components. On steel surface treated to form a hard, wear-resistant, durable film, and provide long-lasting cathode protection.

Property ofZinc Rich Epoxy Primer Paint

- B. The treated steel with excellent adhesion and corrosion performance.C. Good abrasion resistance, impact resistance.D. As a shop primer does not affect the performance of cutting and welding.E. It can be designed to support a variety of paint as a primer, especially heavy industrial and marine environment protection system.F. Quick drying, can recoat after a short time.

Application of TheZinc Rich Epoxy Primer

Widely applicable to long-term anti-rust primer for steel primer, primer and maintenance, ships, bridges and other steel structures. Especially suitable for industrial, chemical, steel and other heavy-duty offshore matching zinc primer spray paint.

Surface Preparation of The Epoxy Zinc-Rich Prime

The surface roughness of steel welds, rounded edges and clear the splash-melt welding, cleared the surface of the grease, oil and other pollutants; surface sandblasted to ISO standard Sa2.5 level or power tools rust St3 level; surface roughness of 50-85um, before spraying to ensure the surface is dry and clean.The weather is good, the substrate temperature of not less than 5 ℃, relative humidity <85%. It must have good ventilation conditions in confined areas to ensure proper drying of the film. Before fully cured coating should not be exposed to oil, chemicals or mechanical stress.

Coating Application ofZinc Rich Epoxy Paint

Mixing mass ratio: Base material (A): The curing agent (B) = 10: 1.Theoretical amount: 220 g / m2.Painting passes: spraying or brushing 2 to 3, 60 to 80 microns dry.Mixing: Use a power mixer component A (base) Stir, then stirring state by mixing ratio of the added amount of group B (curing agent), and fully mixed, while stirring continued momentum needed painting.Thinner or Cleaner: For supporting diluent.Curing time: After mixed directly.After mixing pot life: 5 hours (23 ℃).

The Construction Method of Epoxy Zinc-Rich Prime

Brush: Recommended for small areas, acute sites and pre-coated and refinishing, but must meet the specified dry film thickness.Spraying: airless spray or air spray, the airless spray is recommended priority.Air spray: a discharge pressure 0.4-0.7Mpa, nozzle diameter 1.8-2.2mm;Airless Spray: discharge pressure 15Mpa, nozzle diameter 0.43-0.48mm;* When used in spray paint, because the need to adjust the viscosity, can be added to a thinner 0-10%.PrecautionsA. The construction and curing required to maintain adequate ventilation.B. Premature exposure to rain or condensation in the state, its color and luster affected.C. Heat resistance: resistance up to 200 ℃ dry heat.D. Weather resistance: can occur when there is no separate outer protective coating exposed some of chalking and yellowing;E. Chemical resistance: resistant to most alcohols, aromatic hydrocarbon solvents and solvent spills and overflows; not directly used in the acidic environment of use; if no suitable overcoat Do not use strong alkaline environment; when a suitable overcoat when neutral salts, basic salt resistance is excellent.F. Wear resistance: completely cured after a good wear resistance.G. Compatibility: polyurethane-based coating can be used with good support.

Shelf Life of The Epoxy Zinc-Rich Prime

Twelve months from the date of manufacture in the original unopened container at 32°C. Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat or ignition.Package: 20 kg/ barrel.Contact us get more details about Epoxy Zinc-Rich Primer Coating, such as TDS, Application Method, OEM etc.

Technical Data of The Epoxy Zinc-Rich Prime

|

UNCURED |

|

|

Appearance |

Thick paint |

|

Viscosity |

1700-2200 cP |

|

Cure System |

The catalyst cure |

|

Table Dry |

|

|

CURED At standard conditions (25℃and 50% relative humidity) for 5 days |

|

|

Hardness |

H ( pencil hardness) |

|

Color |

Colored |

|

Gloss |

Flat-high light |

|

Adhesion |

1 |

Ruisenis a professional silicone coating suppliers. We provide High Voltage Insulator Coating Series, Electric Cleaning Agent, zinc rich primer paint, zinc primer coating, epoxy zinc primer, zinc rich primerand so on. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| High Voltage Insulator Coating Series | High Voltage Insulator Coating(HVIC) is used on excessive voltage insulators to forestall flashover and arcing, particular in severely contaminated... | |

| Silicone Rubber Shield for Porcelain Insulators | Silicone Rubber Shield for Porcelain Insulatorscan used to protect the 10-35kV overhead power line insulators (such as pin porcelain insulator, cap... | |

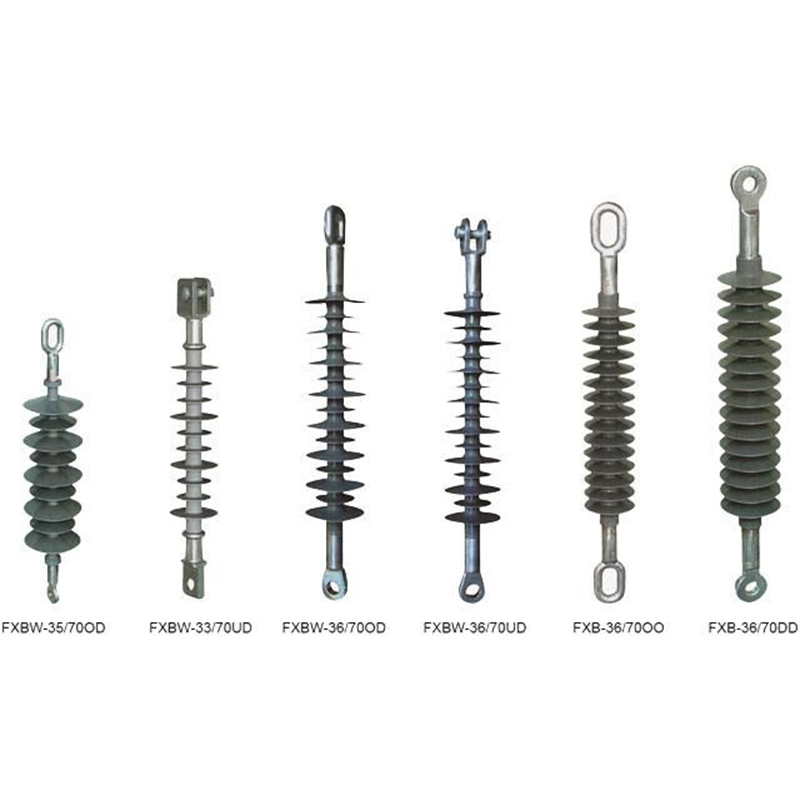

| Composite Insulator | Those silicone rubber insulator manufactureroffer different kinds of composite insulator for substation. Contact us get more details about composi... | |

| elf-cleaning & Anti-tracking Coating SRTV | Well solve the hydrophobicity loss problem of silicone rubber external insulation when in continual rainy and wet weather. It also helps to lessen ... | |

| Pin Type & Other Medium Voltage Line Post Insulator | We offer different kinds of pin type and medium voltage insulator for distribution system. Contact us get more details about pin type and medium v... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |