Cassava Chips Cutting Machine

Cassava Chips Process Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.

Goodway has 27 years of combined experience in thecassava chips slicerand cassava chips processing production line.

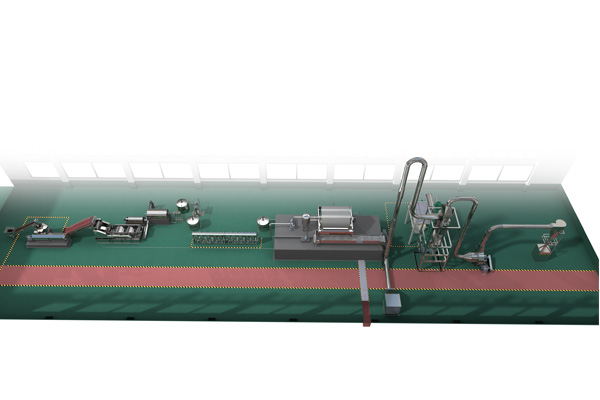

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips production process.

Cassava Chips Production Process

cassava chips production process

Cleaning and Washing Cassava Roots

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

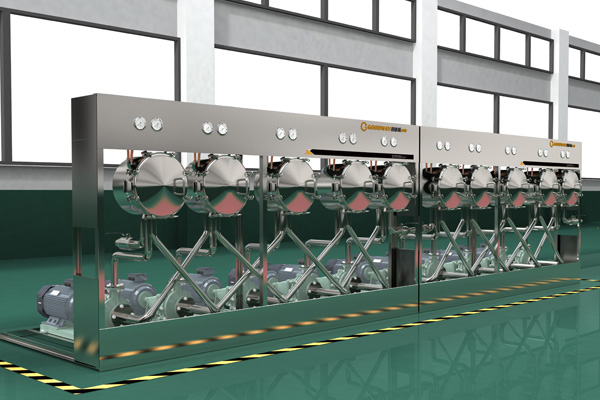

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter bladeof the cassava cutting machine, then cut the chips into strips by the cross cutter blade.

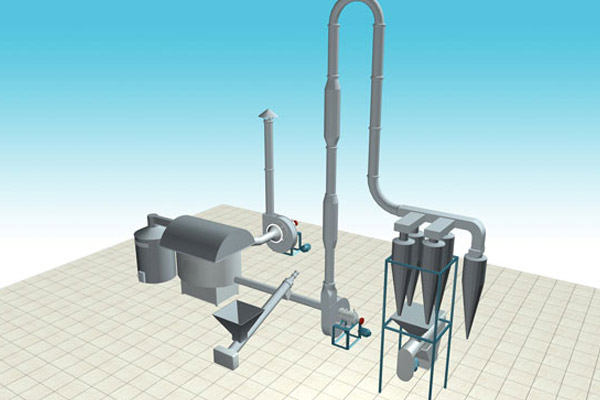

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Sweet Potato Starch Machine | Features of Sweet Potato Starch Machine Sweet Potato Starch Machine Sweet Potato Starch Process Description and Flowchart: Goodway has been co... | |

| Cassava Garri Fryer | Features of Cassava Garri Fryer Processing Capacity: 100-300kgs/hour Application Scope: Garri frying or roasting Product Introduction: garri fryer,... | |

| Cassava Stone Cleaning Machine | Features of Cassava Stone Cleaning Machine Used to remove the stones in the material such as rigid particles of impurities, at the same time have ... | |

| Airflow Flash Dryer(Cassava Drying Machine) | Features of Airflow Flash Dryer(Cassava Drying Machine) The starch factory at present normally adopt airflow drying (also called flash dryingor fl... | |

| Fufu Machine | Features of Fufu Machine Fufu machine for sale- Make Fufu(foofoo) from Fresh Cassava Fufu Process Description and Flowchart: Fufu (variants of... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |