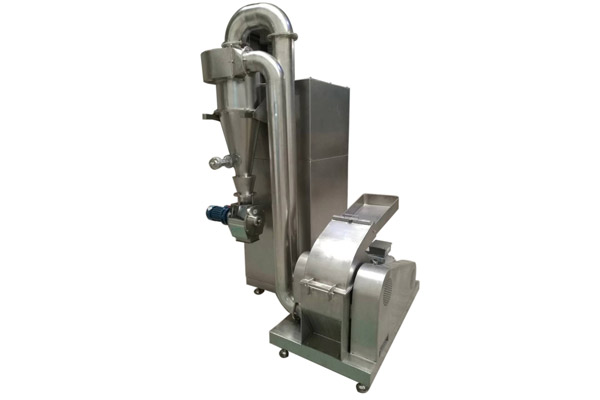

Cassava Chips Cutting Machine

Cassava Chips Process Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.

Goodway has 27 years of combined experience in thecassava chips slicerand cassava chips processing production line.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips production process.

Cassava Chips Production Process

cassava chips production process

Cleaning and Washing Cassava Roots

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter bladeof the cassava cutting machine, then cut the chips into strips by the cross cutter blade.

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Send product request

Other supplier products

| Potato Washing Machine | Features of Potato Washing Machine Processing Capacity: 3-20Tons/hour Application Scope: Fresh cassava washing to remove surface mud and sand Pr... | |

| Hydraulic Dewatering Press | Features of Hydraulic Dewatering Press Processing Capacity: 100-500kgs/hour Application Scope: Cassava slurry dewatering Product Introduction: Hydr... | |

| Cassava Flour Milling Machine | Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Pro... | |

| Fufu Machine | Features of Fufu Machine Fufu making machine for sale - Make Fufu(foofoo) from Fresh Cassava Fufu Process Description and Flowchart: Fufu (vari... | |

| Cassava Chips Cutting Machine | Features ofCassava Chips Cutting Machine Cassava Chips Process Description and Flowchart: Cassava chips are one kind of chips or slices made fro... |

Same products

| YC160W Wheel excavator YC160W | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |