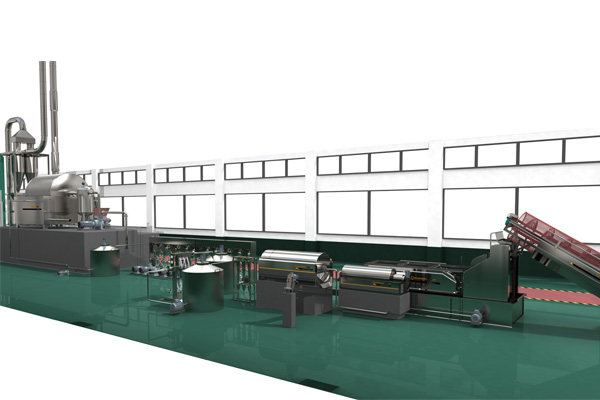

Cassava Garri Fryer

Features of Cassava Garri Fryer

Processing Capacity: 100-300kgs/hour

Application Scope: Garri frying or roasting

Product Introduction: garri fryer, cassava fryer machine, cassava frying machine, cassava roasting machine, cassava drying machine for cassava garri processing

Roasting is done mechanically using an automated Garri fryer made of stainless steel material and with electricity, natural gas, firewood or charcoal as the heat source. The finished product (Garri) is usually recognized from the color change from white to cream (for non-palm oil fortified Garri) and crispy hand feel of the grains/particles.

Product Structure of Garri Fryer Machine

- garri fryer machinehas a flat pot with stainless steel material, with few overall roundness errors, with a pot stirrer affixing high, avoid the paste pot phenomenon.

① Electric: A large heated area, temperature-controlled, heat evenly.

② Gas: Easy to use, fast heating, meet some of the demand for high temperature, unrestricted factory voltage.

③ Coal: Original heat source used for local traditional garri processing.

All parts of the frame body and all food contact areas are 304 stainless steel and polished, consistent with "People's Republic of China Food Sanitation Law" requirements, with beautiful appearance, reasonable design, compact structure, easy installation, simple operation, easy maintenance.

Technical Parameters of Garri Fryer Machine

|

Modelno. |

GD-EF-1200 (Electric heating) |

GD-GF-1200 (Gasheating) |

|

Machinematerial |

Stainlesssteel |

Stainlesssteel |

|

Capacity |

150-200KG/H |

150-200KG/H |

|

Power |

18KW |

|

|

Voltage |

380V/50Hz3Phase |

380V/50Hz3Phase |

|

Rotatespeed |

29R/Min |

29R/Min |

|

Heattransferarea |

2m2 |

2m2 |

|

Operatingtemperature |

150-180℃ |

150-180℃ |

|

The innerdiameterofthe pot |

1200mm |

1200mm |

|

Innerdepthofthe pot |

400mm |

400mm |

|

The innervolumeofpot |

400L |

400L |

|

Weight |

750KG |

750KG |

|

Dimension(L×W×H)(mm) |

1500×1500×1250 |

1660×1400×1200 |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Cassava Starch Machine | Features of Cassava Starch Machine Cassava (tapioca) Starch Processing Machine Cassava (tapioca) Starch Process Description and Flowchart: Goo... | |

| Cassava Processing Machine | As one of cassava processing machines manufacturersand cassava processing machinery suppliers, Goodway can provide the complete set of from cassava... | |

| Cassava Sieving Machine | During the production process of cassava starch, the sieving section is used to separate the fine residues(fiber) from the cassava slurry, remove t... | |

| Cassava Crusher | During the production process of fresh cassava, the crushing section is very important for the quality of final products, the cassava crushermachin... | |

| Potato Starch Making Machine 2019 | Potato Starch Process Description and Flowchart: Goodway has been continuously developing potato starch making machine since 1991 to maximize produ... |

Похожие товары

| YC160W Wheel excavator YC160W | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |