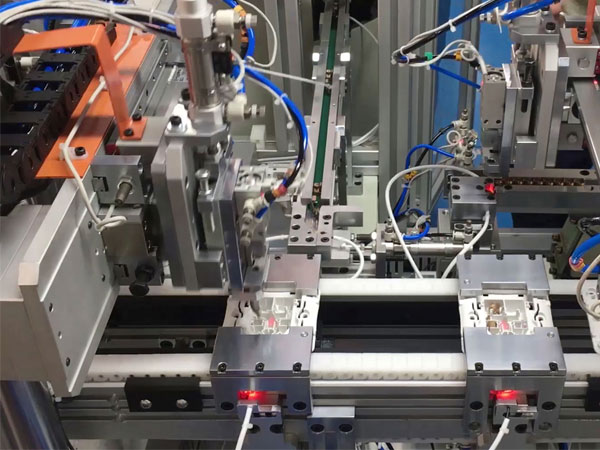

Conveying

Conveyors are used for product conveying. There are different types of the conveyor, which can be used for conveying various kinds of products.

Flexible conveyor is a device designed to transport raw materials, semi-finished products or products in order to improve the efficiency of processing or conveyor production. The products can be conveyed from one place to another. There are a large number of different types of conveyors designed to convey different types of products or perform specific tasks. Yiheda can provide you with automatic feed conveyor.

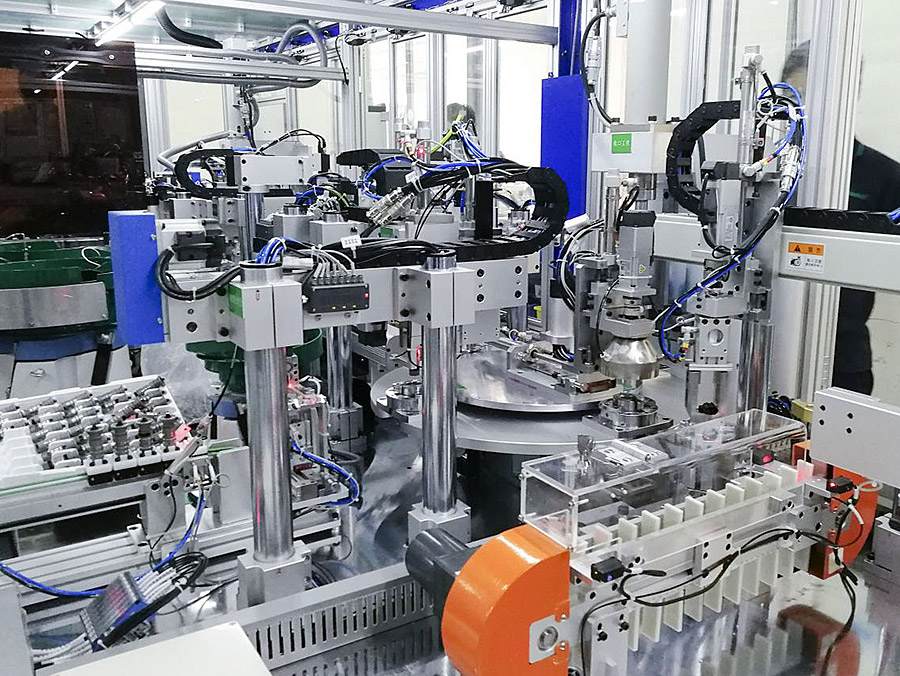

The functions of feeding mechanism of CNC lathe

The functions of feeding mechanism of CNC lathe: The automated feeding manipulator of NC lathe can imitate some movement functions of the human hand and arm, and is used to grasp and carry objects or operating tools according to fixed procedures. It can replace the heavy labor to achieve mechanization and automation of conveyor production line, and can operate in harmful environment to protect personal safety. The automated feeding manipulator of NC lathe is usually used as an additional device of machine tools or other machines, such as loading and unloading and transferring work pieces on NC lathe.

The use of CNC machine tools instead of manual labor can save costs, improve efficiency and reduce the rate of defective. At the same time, it liberates the labor, makes the tedious work flow simple and easy to operate, and greatly reduces the labor cost.

What is the assistant manipulator? What is the purpose of the assistant manipulator?

What is the assistant manipulator? It is a new kind of auxiliary equipment used for labor saving in material handling and installation. It skillfully applies the balance principle of force to form a gravity-free floating state of materials in the air, that is, the gravity of materials is balanced by the automatic conveyor belt system, so that the operator can balance the movement and positioning of materials in space only by pushing and pulling the materials.

The assistant manipulator balances the gravity of the object through the thrust or pull force generated by the cylinder to achieve the assistant effect. By detecting the end fixture of the sucker or the manipulator and balancing the gas pressure in the cylinder, it can automatically identify whether there is a load on the manipulator arm of the manipulator, and automatically adjust the air pressure in the balancing cylinder through the pneumatic logic control loop to achieve the purpose of automated balance. When working, heavy objects are suspended in the air to avoid collision between products.

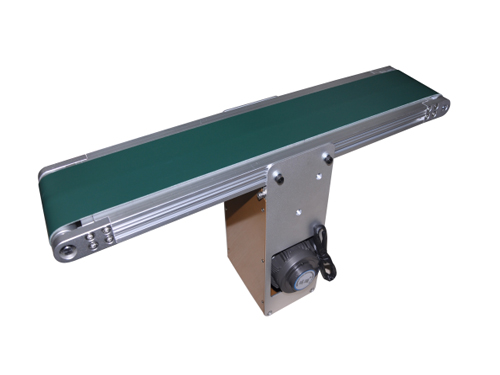

Basic knowledge of the belt conveyor

The basic knowledge of the automatic conveyors is mainly divided into: daily maintenance knowledge, conveyor limitations and conveyor operation rules.

First, what are the daily maintenance of belt conveyor?

1. check whether the belt is degumming.

2. check whether spring is loose or deformed and replaced.

3. check whether the motor has abnormal sound.

Second, what are the limitations of the belt conveyor?

The gradient of belt, the length of conveying material, the nature of conveying material, the width of belt, the running speed of belt, etc.

In addition, there will be special belts for different materials; for example, the belt with bucket slope can be close to 90 degrees, and the gradient of pattern belt can also be relatively large.

Third, what departments are widely used in belt conveyors?

Large ones for coal and mining; small ones for electronics and electrical appliances, and some for chemical industry, tobacco, plastic, etc.

There are also food industries, such as biscuits, bread and so on. The automatic conveyor for industrial automation is only one kind of conveying equipment. Conveying equipment is widely used in industries, such as automobiles, household appliances and so on.

Four, operation rules of the belt conveyor

1.The fixed conveyor should be installed on a fixed basis according to the prescribed installation method. Before the formal operation of the mobile conveyor, the wheel should be wedges with triangular or brake. In order to avoid moving in the work, there should be a one-meter channel between the machine and the machine, and between the machine and the wall when there are several conveyors working in parallel.

2.Before using the conveyor, it is necessary to check whether the running parts, belt buckles and carrying devices are normal and whether the protective equipment is complete. The tightness of the tape must be adjusted to a proper level before starting.

3.The belt conveyor should start at no load. After the operation is normal, the material can be fed. No feeding before driving.

4. When several conveyors are connected in series, they should start from the unloading terminal and start in sequence. After normal operation, the material can be fed.

5. When the tape runs off during operation, stop and adjust it, so as not to use it reluctantly, in order to avoid wearing edges and increasing load.

6. The working environment and the temperature of the delivered material must not be more than 50 degrees centigrade and less than -10 C. It is not allowed to convey materials containing acid and alkali oils and organic solvents.

7. No pedestrians or passengers are allowed on the conveyor belt.

8. Before stopping, the conveyor must stop feeding before stopping the material on the belt.

9. The conveyor motor must be well insulated. Cable of mobile conveyor should not be dragged or dragged. The motor must be grounded reliably.

10. When the belt slips, it is strictly prohibited to pull the belt by hand to avoid accidents.

What are the advantages of automated loading and unloading?

There are three main advantages of automated loading and unloading.

(1)High production efficiency: To improve production efficiency, we must control the production rhythm. Except that the fixed production and processing rhythm can not be improved, automated feeding and unloading replaces manual operation, so that the rhythm can be well controlled, avoiding the impact of human factors on production rhythm, greatly improving production efficiency.

(2)Flexible process modification: We can quickly change the production process by modifying the procedures and gripper fixtures. The debugging speed is fast, and the training time for employees is not needed, so it can be put into production quickly.

(3) Improve the quality of work pieces: Use robot auto conveyor systemsand production line conveyor systems. From feeding, clamping to blanking, it is totally completed by robots, which reduces the intermediate links and greatly improves the quality of parts, especially the work piece surface is more beautiful.

Dongguan Yiheda Automation Co., Ltd. was established in 2010. Yiheda has 1700 staffs including 110 automation R&D personnel, specializes in designing and manufacturing the custom automation solution to customers, such as automatic industrial machines, automatic machines, assembly solutions, industrial automation design.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Automatic Assembly | Nowadays, assembly automation technologyis gradually replacing the manual assembly, since it can reduce labor costs and improve production efficien... | |

| Conveying | Conveyors are used for product conveying. There are different types of the conveyor, which can be used for conveying various kinds of products. Fle... | |

| Feeding System | The feeding component is used for material automatic feeding includes screw feeding machine, automatic supplement machine and material hopper mac... | |

| OCV Full-Automatic Assembly Line | The VVT(OCV)is one of accessories of automotive engine, which was used to control the inlet of engine. VVT(OCV) , electromagnet coil assembly line ... | |

| Belt conveyor (Short type) | The conveyor works with automatic machine and other conveyors. There are many kinds of materials that can be conveyed by the conveyor, with complet... |