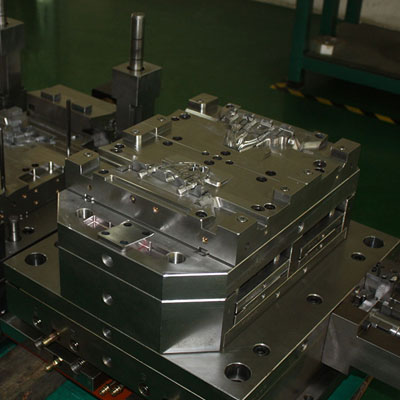

2K Mould

2KMoulding Definition

The part molding by 2K Mouldhas been recognized by more and more people because it is superior to traditional injection-good structures and appearances. 2K or 'two-shot' injection moulding consists of processing two different polymers (or two different colors of one polymer) into an end product by means of one injection moulding process.

A two-color injection mould refers to a double shot injection molding processin which two different materials are injection molded into the same set of moulds to form an injection molded part from two materials. Some materials are of two different colors, some are soft and hard, and are molded by the same injection molding machine with two sets of injection mechanical equipment (two-color injection molding machine), and two kinds of plastics are injected in sequence.

After the mold is clamped, the first material is injected into the mold to form first plastic parts, and after the injection is completed, the mould is opened, the first product is left in the core side, and the template is rotated by 180 degrees, then the mould is closed again and the 2nd plastic resin is injected into the mould through the second barrel to form a two-color product.

What is the difference between a 2K mould and a normal mould?

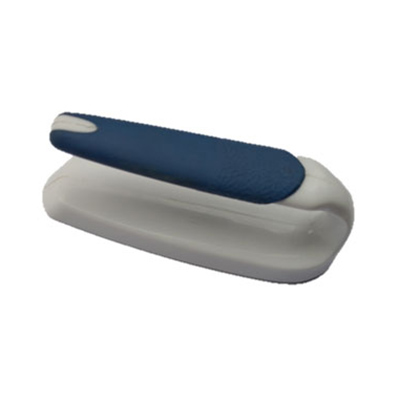

The appearance of the product made by the two-color mould is more beautiful than that produced by the single-color mold, and it is easy to change the color without painting. The disadvantage is the high cost and high technical requirements.

The double shot mouldingis formed by mixing two materials, The two materials must have good bonding strength. In order to ensure good bonding strength, the bonding performance test must be carried out first, and the bonding performance is confirmed to be put into production.

The two cores of the 2K mould are the same, and the cavity is different.

The cavity and core of the double shot mould must be matched, which requires precise positioning of the mold base.

In the second injection molding of the two-color mold, in order to avoid the 2nd cavity scratching the first molded product, it is possible to design some clearance, but the strength of each sealing position must be carefully considered.

Two-color product application range:

Product function requirements, such as some light-transmitting buttons, power switch, remote control buttons, car switches, etc..

Improve the touch feel. Some hand-held products use soft rubber to feel comfortable, such as toothbrushes.

Increase the aesthetic appearance of the product, such as some two-color buttons and the logo of appearance parts, which are beautiful and will not be rubbed off.

The top and bottom covers of some electronic products, or the plastic cover with waterproof performance.

The nozzle of the 2k injection mouldingmachine mainly has two parallel injection systems or is L-shaped.

As a two shot moulding ltd, we have types of custom plastic injection molding chinafor sale, if you have needs, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Two Shot Molding Parts | Two Shot Tool Construction Part two shot tool construction saves the injection machine quantity and plant area, lower the labor cost and minimize ... | |

| Automotive Molding Parts | Injection Molding Automotive Parts Hanking mouldinvolves various automotive injection plastic mold oem, our engineers are familiar with the charac... | |

| Industrial Molding Parts | Industrial hanking mould parts are referred to the plastic parts of industrial products, HanKing Mould Enginering Ltd.preferred to think of it as n... | |

| Plastic Parts Gallery | It is a complex task to design plastic parts involving many factors according to varoius requirements for different industires. "How is the part to... | |

| Gear Mold | Custom Plastic Gear Injection Mold Making, with many different dimensions and material, 2 cavities or 4 cavities customized plastic gear mold. HanK... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |